Exploring Custom Centerless Grinder Tables Enhancing Precision and Efficiency in Modern Manufacturing

In the world of precision manufacturing, the need for accuracy and efficiency cannot be overstated. Custom centerless grinder tables play a pivotal role in achieving both of these critical elements. These specialized tables allow for intricate grinding processes that ensure high-quality finishes on various metal components. This article delves into the significance of custom centerless grinder tables, their benefits, and the factors to consider when investing in these essential tools.

Understanding Centerless Grinding

Centerless grinding is a machining process that eliminates the need for centering the workpiece. This method is particularly advantageous for producing small, cylindrical parts in large quantities, making it a staple in manufacturing industries ranging from automotive to aerospace. The process involves placing the workpiece between two grinding wheels the grinding wheel and the regulating wheel. This unique setup allows for continuous operation and high throughput while maintaining tight tolerances.

The Importance of Customization

While standard centerless grinders serve their purpose, the dynamic nature of modern manufacturing often requires customized solutions to meet specific needs. Custom centerless grinder tables are designed to accommodate unique specifications related to the size, shape, and material properties of the workpieces being processed. By tailoring the grinder table to exact requirements, manufacturers can enhance operational efficiency, reduce waste, and ultimately improve product quality.

Benefits of Custom Centerless Grinder Tables

1. Precision Engineering Custom tables can be engineered to hold workpieces at specific angles and positions, ensuring that grinding is executed with high precision. This leads to tighter tolerances and better overall part quality.

2. Increased Efficiency By optimizing the design of the grinder table, manufacturers can significantly reduce the time taken for each grinding cycle. This results in higher throughput and more efficient use of resources.

3. Versatility Custom grinder tables can be adapted for various applications, including different grinding processes (such as in-feed and through-feed grinding) and material types. This versatility allows manufacturers to meet diverse customer needs without sacrificing quality.

4. Reduced Downtime A custom solution can minimize machine setup times. When the grinder table is designed specifically for the intended application, operators can switch between tasks more quickly, leading to less downtime and higher productivity.

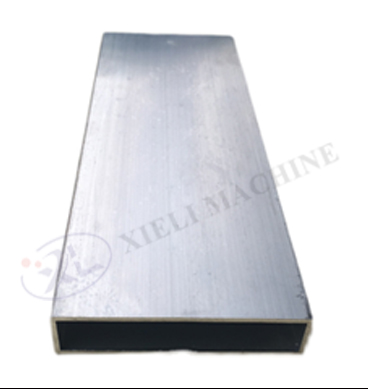

custom centerless grinder tables

5. Improved Ergonomics Custom tables can also enhance the ergonomics of the grinding process. By designing tables that are easy to adjust and operate, manufacturers can ensure a safer and more comfortable work environment for operators.

Factors to Consider When Investing

When considering a custom centerless grinder table, manufacturers should keep several factors in mind

- Material Compatibility Ensure that the table can support the types of materials that will be processed. Different materials may require specific handling and support to achieve desired results.

- Size and Space Constraints Assess the available floor space and the size specifications of the workpieces. Custom tables should be designed to fit seamlessly into existing production setups.

- Integration with Existing Equipment Custom tables must be compatible with current machines and workflows. This may require collaboration with engineers to ensure smooth integration.

- Cost Considerations While investing in custom solutions may have higher upfront costs, the long-term benefits in efficiency and quality often outweigh these expenses. Manufacturers should evaluate the return on investment (ROI) when considering customization.

- Supplier Expertise Choosing a supplier with experience in developing custom centerless grinder tables is essential. Their knowledge can greatly influence the table's design, ensuring that it meets performance standards and operational goals.

Conclusion

In the ever-evolving landscape of manufacturing, the demand for precision and efficiency continues to grow. Custom centerless grinder tables provide an effective solution for industries seeking to enhance their grinding processes. By investing in tailored solutions, manufacturers can enjoy improved quality, reduced operational costs, and increased productivity. As technology advances and manufacturing requirements become more specialized, the importance of customized equipment, such as centerless grinder tables, will only continue to rise.