The Rising Demand for Stainless Steel Pipe Polishing Machines A Focus on Chinese Suppliers

In today's global manufacturing landscape, the demand for high-quality stainless steel products is on the rise. One critical aspect of the production of stainless steel pipes is the polishing process, which not only enhances the aesthetic appeal of the pipes but also improves their corrosion resistance and overall durability. In this context, stainless steel pipe polishing machines have gained significant importance. This article delves into the growing need for these machines and highlights prominent suppliers based in China.

Importance of Stainless Steel Pipe Polishing

Stainless steel is widely used across various industries, including automotive, construction, and food processing, owing to its excellent mechanical properties and resistance to corrosion. However, raw stainless steel pipes often have uneven surfaces, scratches, and other imperfections that need to be addressed to meet industry standards. Polishing these pipes is crucial for several reasons

1. Enhanced Aesthetic Appeal A polished surface is visually appealing, which is essential in applications where appearance matters, such as architectural projects or consumer products.

2. Improved Resistance to Corrosion Polishing removes impurities and oxidation layers from the surface, thereby enhancing the corrosion resistance of stainless steel. This is particularly important in environments exposed to moisture and corrosive substances.

3. Better Hygiene Standards In industries like food processing and pharmaceuticals, polished stainless steel is easier to clean and sanitize, making it a preferred material.

4. Increased Longevity By reducing surface imperfections, polishing can extend the lifespan of stainless steel pipes, resulting in cost savings over time.

The Role of Polishing Machines

Polishing machines are essential for achieving the desired finish on stainless steel pipes. They employ various methods, such as mechanical polishing, electropolishing, and abrasive polishing, to smooth the surface effectively. The choice of machine depends on several factors, including the size of the pipes, the required surface finish, and the production volume.

Chinese Suppliers Leading the Market

China has emerged as a significant player in the manufacturing and supply of stainless steel pipe polishing machines. Several factors contribute to the prominence of Chinese suppliers in this field

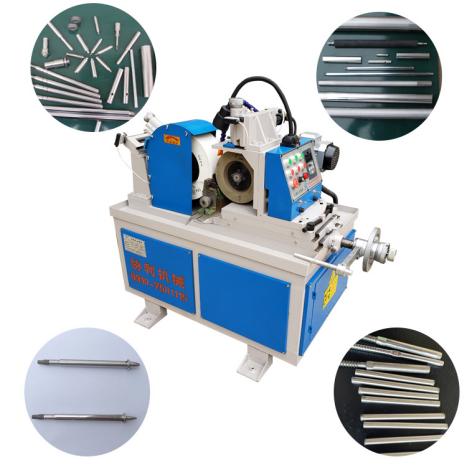

stainless steel pipe polishing machine china suppliers

1. Innovative Technology Chinese manufacturers invest heavily in research and development, resulting in advanced polishing machines that offer precision and efficiency. Many machines now incorporate automation and digital control for enhanced performance.

2. Cost-Effectiveness The competitive pricing of machines produced in China makes them attractive to businesses worldwide. This cost advantage often stems from lower labor costs and a well-established supply chain.

3. Diverse Product Range Chinese suppliers offer a wide variety of polishing machines tailored to different applications. From small-scale operations to large industrial facilities, there’s a machine suitable for every need.

4. Export Infrastructure With a robust export infrastructure, Chinese suppliers can easily reach international markets, making it simpler for foreign buyers to acquire stainless steel pipe polishing machines.

Notable Chinese Manufacturers

Several Chinese companies have garnered a reputation for manufacturing high-quality stainless steel pipe polishing machines. Some of the notable ones include

- Jiangsu Lijin Machinery Recognized for its state-of-the-art polishing technology and a wide range of machines designed for different industries.

- Zhangjiagang Lianxin Machinery Specializes in customized solutions and has a strong focus on quality control, ensuring that each machine meets international standards.

- Wuxi Mingtai Offers a variety of polishing machines and provides excellent after-sales service to customers around the globe.

Conclusion

The increasing demand for stainless steel pipes in various sectors necessitates the use of efficient polishing processes to ensure quality and compliance with industry standards. Chinese suppliers of stainless steel pipe polishing machines play a crucial role in meeting these demands through innovative technology, competitive pricing, and a diverse range of products. As industries continue to evolve, the role of these machines and their suppliers will remain vital in shaping the future of stainless steel production. Investing in high-quality polishing technology is, therefore, a strategic move for businesses aiming to enhance their product offerings and maintain a competitive edge in the market.