Centerless OD Grinder Exporter A Key Player in Precision Manufacturing

In the world of precision manufacturing, the centerless OD (outer diameter) grinder stands out as a crucial machinery for achieving high accuracy and efficiency in the grinding process. As globalization continues to expand markets, the role of centerless OD grinder exporters has become increasingly significant. These exporters facilitate the distribution of advanced grinding technology to various industries worldwide, including automotive, aerospace, and electronics.

Understanding Centerless OD Grinding

Before delving into the significance of exporters, it’s essential to understand what centerless OD grinding is. This grinding method involves the removal of material from a workpiece without the need for a fixture or holding device. The workpiece is typically supported by the grinding wheels and a regulating wheel, allowing for consistent and precise cylindrical shapes. This method is particularly favored for its ability to handle long, slender parts that require tight tolerances.

Centerless grinding offers several advantages over traditional grinding processes. It significantly increases throughput, reduces setup time, and allows for the grinding of multiple parts simultaneously. These factors make it a go-to solution for manufacturers seeking cost-effective and efficient production methods.

The Role of Exporters in the Market

Centerless OD grinder exporters play a pivotal role in the availability and dissemination of this technology outside its country of origin. They ensure that the latest advancements in grinding machinery reach manufacturers across the globe. The technology varies widely, and exporters often provide a range that can cater to different production needs—ranging from basic models to highly automated and digitally controlled machines.

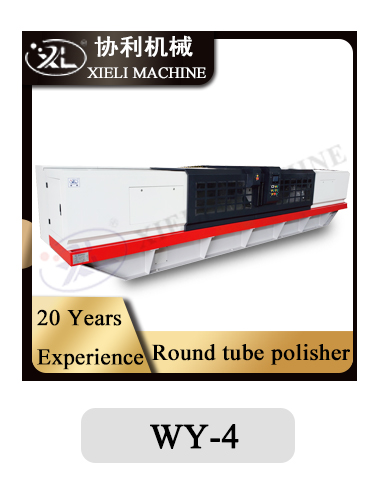

centerless od grinder exporter

In recent years, demand for centerless grinders has surged due to the increasing need for high-quality finished products. Industries such as automotive manufacturing, where precision components like shafts and rods are critical, require the reliability of centerless grinders. Exporters bridge the gap by supplying quality machines that adhere to international standards, ensuring that manufacturers can maintain competitiveness in their respective markets.

Quality and Compliance in Exporting

When it comes to exporting centerless OD grinders, quality assurance is paramount. Exporters must ensure that the machinery they provide complies with regulations set by both the exporting and importing countries. This includes adherence to safety standards, energy efficiency requirements, and technological advancements. Reputable exporters often collaborate with manufacturers to conduct thorough inspections and quality checks before shipment.

Moreover, as sustainability becomes increasingly important in manufacturing, many exporters are turning towards delivering eco-friendly options. This includes machines designed for energy efficiency and reduced waste, aligning with global efforts to maintain sustainable industrial practices.

Conclusion

In conclusion, centerless OD grinder exporters serve as a vital link in the global supply chain of precision manufacturing technology. Their contribution goes beyond merely selling machines; they provide manufacturers with the tools necessary to enhance productivity and improve product quality. In a world where technological advancements happen at a rapid pace, these exporters ensure that businesses have access to cutting-edge solutions that can meet modern manufacturing demands.

As industries continue to evolve, the significance of centerless OD grinders and their exporters will undoubtedly grow. The combination of precision machining, increased production efficiency, and a focus on quality positions centerless grinders as an indispensable asset in the toolkit of manufacturers worldwide. Therefore, choosing a reliable centerless OD grinder exporter is crucial for any business looking to enhance its manufacturing capabilities and remain competitive in the global market.