The Rise of Wholesale Surface Polishing Machines Enhancing Industrial Efficiency

In the modern manufacturing landscape, efficiency and quality are paramount. With industries increasingly focusing on output and precision, wholesale surface polishing machines have emerged as essential tools for a variety of sectors, including automotive, aerospace, and consumer goods. This article explores the significance of wholesale surface polishing machines, their benefits, and the innovations driving their adoption.

Understanding Surface Polishing Machines

Surface polishing machines are equipment designed to refine the surfaces of materials, improving their aesthetics and functionality. They are widely used to create smooth, shiny finishes on metals, plastics, and other materials. The polishing process not only enhances the visual appeal but also plays a crucial role in preparing surfaces for further treatment, such as painting or coating.

The Importance of Wholesale Supply

Wholesale suppliers play a vital role in making surface polishing machines accessible to a broader range of businesses. By offering these machines at competitive prices, wholesalers enable small and medium-sized enterprises (SMEs) to invest in high-quality equipment without straining their budgets. This democratization of advanced manufacturing technology helps companies improve their production processes and maintain competitiveness in their respective markets.

Benefits of Wholesale Surface Polishing Machines

1. Cost Efficiency One of the most significant advantages of purchasing from wholesalers is the cost savings. Businesses can acquire machine tools at reduced prices, allowing for better allocation of financial resources to other areas, such as research and development.

2. Quality and Reliability Wholesale suppliers often have established relationships with manufacturers, ensuring that the machines they provide meet industry standards. High-quality machines lead to better polishing results, which translate into enhanced product quality and customer satisfaction.

3. Bulk Purchasing Options For larger manufacturers, purchasing wholesale allows for bulk buying. This not only further reduces costs but also ensures consistent equipment availability, crucial for maintaining continuous production processes.

4. Access to Advanced Technology Wholesalers tend to stock the latest models of surface polishing machines, incorporating cutting-edge technologies such as robotics and automation. This access helps businesses stay ahead of the curve in an increasingly competitive landscape.

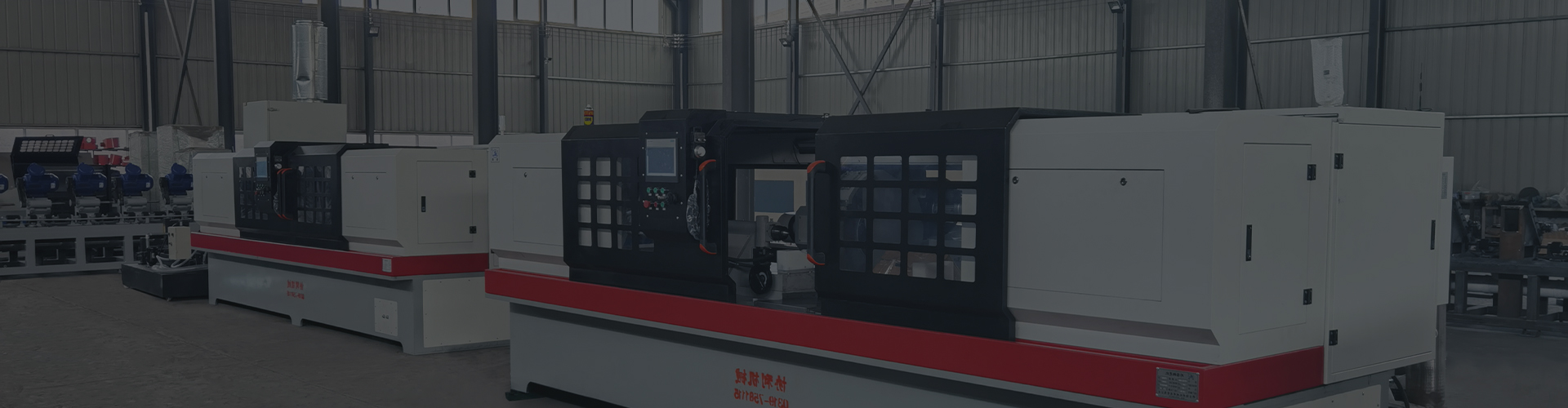

wholesale surface polishing machine

5. Technical Support and Training Many wholesale suppliers offer support and training for their machines, ensuring that businesses can make the most out of their investments. This support is invaluable, especially for SMEs that may lack the in-house expertise to implement advanced machinery.

Innovations in Surface Polishing Technology

The market for surface polishing machines is evolving rapidly. Innovations such as automated polishing systems, CNC machines, and eco-friendly polishing agents are revolutionizing how industries approach surface finishing.

1. Automation The integration of robotics into surface polishing machines allows for higher precision and consistency. Automated systems can operate continuously, significantly increasing output and reducing labor costs.

2. Computer Numerical Control (CNC) CNC polishing machines can be programmed to execute complex polishing tasks automatically. This technology not only enhances consistency but also allows for intricate designs that manual polishing could not achieve.

3. Sustainability With increasing environmental concerns, manufacturers are developing eco-friendly polishing solutions. These include biodegradable polishing compounds and machines designed to minimize energy consumption and waste.

4. Smart Technology The advent of Industry 4.0 has introduced smart technologies to surface polishing. Machines equipped with IoT capabilities can monitor performance metrics in real-time, allowing for predictive maintenance and reduced downtime.

The Future of Wholesale Surface Polishing Machines

As industries continue to evolve, the demand for high-quality surface finishing will only increase. Wholesale surface polishing machines will remain crucial in meeting this demand, especially as technology advances and manufacturing processes become more complex.

Businesses looking to invest in surface polishing machines should consider the benefits of wholesale purchasing, from cost savings to access to cutting-edge technology. As the market expands and innovation continues, wholesale suppliers will play an essential role in shaping the future of surface polishing and industrial manufacturing.

In conclusion, the wholesale market for surface polishing machines not only enhances production capabilities but also drives innovation, ensuring that industries can meet growing consumer demands for quality and efficiency. The continued evolution of this sector promises exciting opportunities for manufacturers and suppliers alike.