Exploring the Homemade Centerless Grinder A Price List Overview

In the world of metalworking and machining, precision is paramount. One tool that has revolutionized the way we grind materials is the centerless grinder. While industrial machines are often costly and large, many enthusiasts and small shop owners are turning to homemade solutions to save money and achieve personalized results. This article delves into the homemade centerless grinder market, providing insight into designs, features, and an overview of potential pricing.

What Is a Centerless Grinder?

A centerless grinder is a type of cylindrical grinder that eliminates the need for a machine operator to reposition the workpiece by using a combination of wheels. The workpiece is held in place by the two grinding wheels, one for grinding and the other for support. This mechanism allows for high-speed and efficient grinding of various materials, making it particularly popular among those who work with precision metal parts.

The Rise of Homemade Solutions

The interest in homemade centerless grinders has surged due to a combination of factors the rising costs of equipment, a desire for customization, and the DIY spirit prevalent in today’s maker culture. By crafting a homemade centerless grinder, individuals can tailor it to their specific needs, using materials they have on hand or sourcing affordable components.

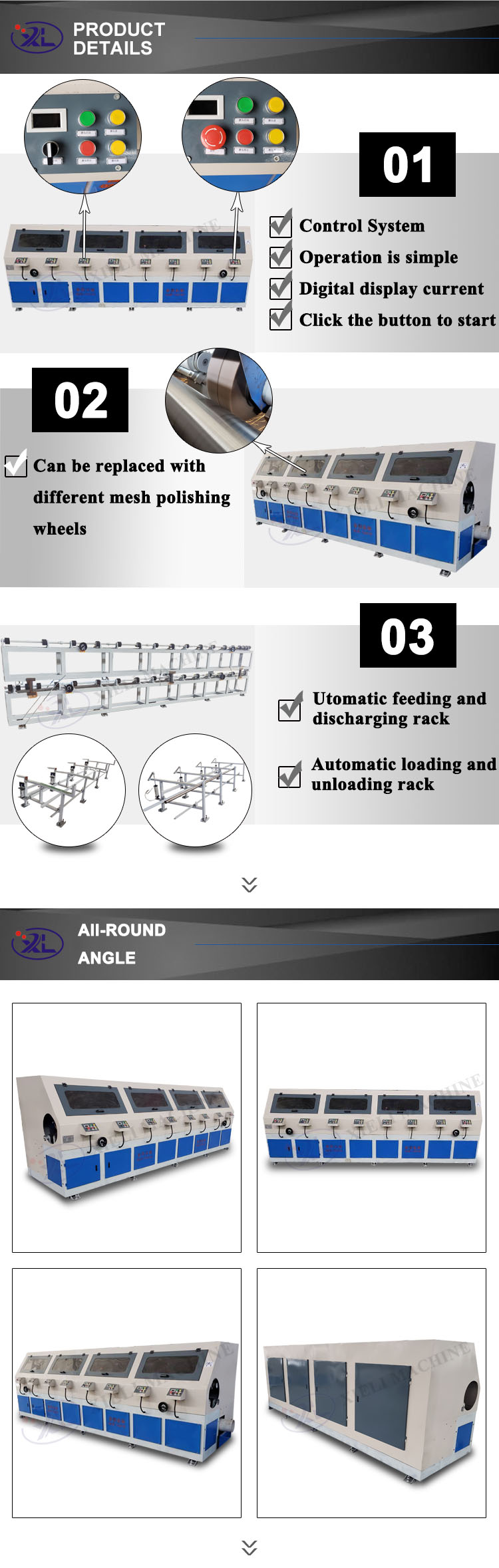

Key Features of Homemade Centerless Grinders

1. Customizability Homemade grinders can be designed to meet specific tolerances and dimensions suitable for the projects at hand. Builders can choose the motor size, wheel specifications, and overall design.

2. Cost Efficiency One of the most significant advantages of creating a homemade grinder is the potential for cost savings. By sourcing used components or repurposing materials, builders can keep expenditures low.

3. Learning Experience Constructing a centerless grinder not only provides a sense of accomplishment but also deepens the builder's understanding of the mechanics involved in grinding and machining processes.

homemade centerless grinder pricelist

Pricing Overview

When it comes to the price of homemade centerless grinders, costs can be dramatically different based on complexity, materials, and the skill level required for assembly. Below is a general overview of potential costs involved in building a homemade centerless grinder

- Basic Chassis Fabricating the main body of the grinder can range from $50 to $200, depending on whether the builder uses new steel, scrap metal, or wood.

- Grinding Wheels The cost of grinding wheels can vary widely. A pair can range from $20 to $100, depending on the material and quality.

- Motor A suitable motor is critical for performance and can be one of the larger expenses. A decent motor suitable for a homemade centerless grinder can cost between $100 and $300.

- Bearings and Hardware Bearings, bolts, and other necessary hardware can accumulate costs that typically range from $30 to $100.

- Miscellaneous Supplies Additional supplies like belts, electrical wiring, and switches might add another $20 to $50.

In total, a reasonably functional homemade centerless grinder could wind up costing anywhere from $300 to $800, depending on choices made throughout the build process. More elaborate designs with higher-end components could push this number higher.

Conclusion

Homemade centerless grinders represent an exciting and cost-effective avenue for metalworking enthusiasts and professionals alike. By understanding the core components, features, and pricing associated with these machines, builders can engage more thoroughly in their projects while also saving money. As the maker community continues to grow, homemade centerless grinders will undoubtedly play a significant role in the future of machining and grinding, empowering individuals to make precision tools tailored to their specific needs. Whether you’re an experienced machinist or a curious beginner, creating your own centerless grinder may just be the next rewarding endeavor on your journey into the world of woodworking and metalworking.