Exploring the Landscape of Retrofit Servo Centerless Grinder Factories

The evolution of manufacturing technology has been pivotal in enhancing productivity and precision in various industries. Among the game-changing innovations is the retrofit servo centerless grinder, a machine that stands out for its efficiency and accuracy in processing cylindrical components. This article delves into the realm of retrofit servo centerless grinder factories, examining their significance, advantages, and the future of this technology.

Understanding Centerless Grinding

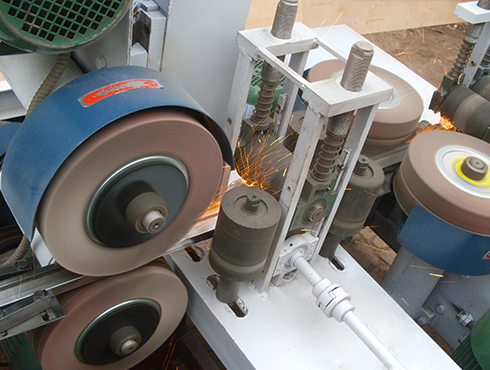

Centerless grinding is a machining process that involves the removal of material from a workpiece without the need for centering or supporting fixtures. Instead, the workpiece is held between two wheels a grinding wheel and a regulating wheel. This unique configuration allows for the production of highly precise cylindrical components with improved surface finishes. However, traditional centerless grinding machines often face limitations in terms of adaptability and operational efficiency.

The Need for Retrofitting

In the competitive landscape of manufacturing, optimizing existing machines for enhanced performance is an attractive proposition. Retrofitting involves upgrading these machines with modern components such as servo motors, CNC controls, and advanced software. By integrating servo technology, manufacturers can achieve greater control over the grinding process, resulting in improved precision, consistency, and productivity. This transformation not only maximizes the lifespan of older machinery but also significantly reduces the costs associated with acquiring new equipment.

Benefits of Retrofit Servo Centerless Grinders

1. Increased Precision Retrofit servo centerless grinders provide superior control over the grinding process. The use of servo motors allows for fine-tuning of parameters, leading to enhanced dimensional accuracy and minimal tolerance deviations. This is particularly crucial for industries that demand high precision, such as aerospace and automotive.

2. Boosted Productivity The integration of modern control systems enables faster adjustment of grinding parameters and real-time monitoring. This results in reduced setup times and minimized downtime, allowing factories to maintain a steady production flow and meet customer demands more effectively.

retrofit servo centerless grinder factories

3. Cost Efficiency Retrofitting existing machinery is often more cost-effective than investing in brand new equipment. It allows factories to leverage their current assets, providing an equitable balance between performance improvement and financial investment.

4. Adaptability The evolving demands of the market require manufacturers to remain flexible. Retrofit servo centerless grinders can be configured to handle a variety of workpieces, making them suitable for different applications and industries without significant retooling.

5. Sustainability By retrofitting existing machines, manufacturers contribute to sustainability efforts. This approach minimizes waste by prolonging the life of equipment, reducing the need for new machine production, and decreasing the overall carbon footprint associated with manufacturing operations.

The Future of Retrofit Servo Centerless Grinders

As technology continues to evolve, the future of retrofit servo centerless grinders looks promising. The ongoing development of artificial intelligence and machine learning will likely play a crucial role in further enhancing grinding processes. Predictive maintenance analytics, for instance, can foresee equipment issues before they become significant problems, leading to higher uptime and operational efficiency.

Moreover, as industries increasingly embrace Industry 4.0 principles, the integration of IoT (Internet of Things) devices could transform retrofit servo centerless grinders into interconnected, smart machines that communicate with each other and share data in real-time. Such advancements will allow manufacturers to optimize their processes with unprecedented insight and control.

Conclusion

Retrofit servo centerless grinder factories represent a vital segment of modern manufacturing, bridging the gap between traditional practices and innovative advancements. By enhancing older machines, the industry can realize significant gains in precision, productivity, and sustainability. As technology evolves, so too will these retrofitted systems, ensuring they remain at the cutting edge of manufacturing capabilities. Investing in retrofit solutions not only revitalizes production lines but also prepares businesses for a future where adaptability and innovation are paramount.