The Evolution and Importance of Pipe Buffing Machine Factories

In the modern manufacturing landscape, the finishing processes are as crucial as the initial production stages. Among these processes, pipe buffing stands out as an essential operation that ensures quality and aesthetic appeal in metal components, particularly pipes. Pipe buffing machine factories play a pivotal role in this area, driving innovation, efficiency, and product quality in various industries.

Understanding Pipe Buffing Machines

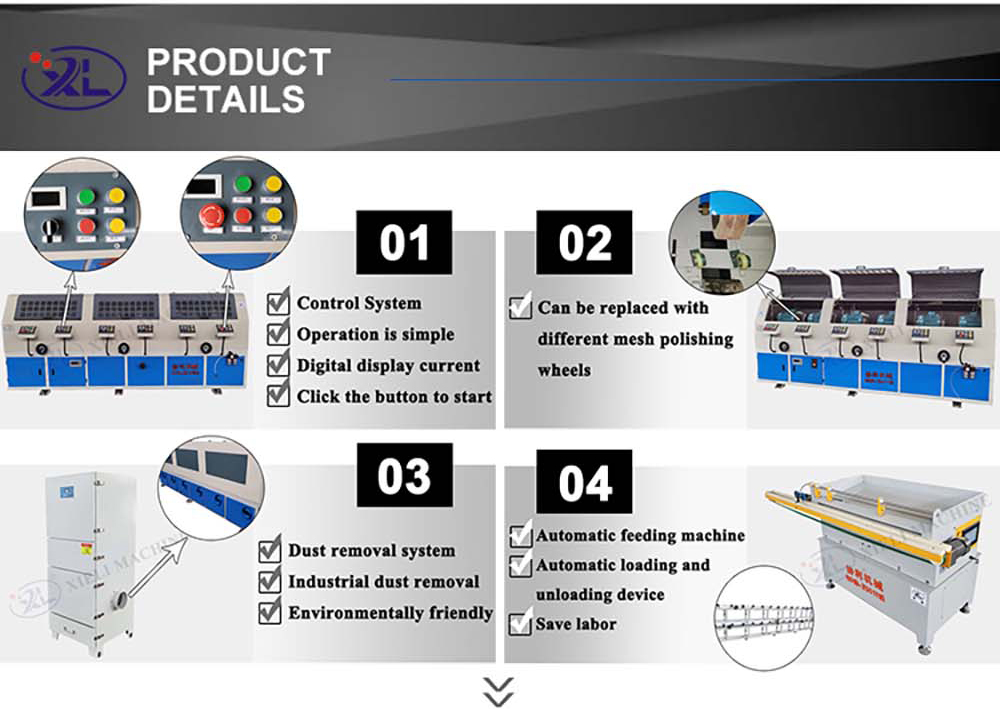

Pipe buffing machines are specialized equipment designed to polish and smooth the surfaces of pipes. This machinery employs various buffing wheels, abrasive materials, and techniques to remove imperfections, scratches, and oxidation from metal pipes, effectively enhancing their surface finish. The primary objective is to create a visually appealing product while also improving its corrosion resistance and overall durability. Industries such as automotive, aerospace, construction, and manufacturing utilize these machines to maintain high standards in their products.

The Role of Pipe Buffing Machine Factories

Factories dedicated to manufacturing pipe buffing machines significantly contribute to industrial efficiency. They not only produce these essential machines but also innovate to meet the ever-evolving demands of different sectors. By investing in advanced technologies and automation, these factories can enhance the productivity of buffing processes. The integration of computer numerical control (CNC) and robotics allows for precision in buffing, reducing human error and inconsistency in quality.

These factories also ensure that pipe buffing machines are customizable to accommodate various pipe sizes and materials. This flexibility enables clients from different industries to acquire machines that fit their specific needs, further enhancing production efficiency.

Quality Control and Standards

Quality control is fundamental in the operation of pipe buffing machine factories. To maintain high-quality products, these factories typically implement stringent quality management systems. This involves regular testing and calibration of machines to ensure they meet international standards. Quality pipes are essential, especially in industries where safety and reliability are non-negotiable, such as in oil and gas pipelines or aerospace components.

pipe buffing machine factories

Furthermore, these factories often adhere to environmental and safety regulations to ensure that their manufacturing processes are sustainable and safe for workers. This commitment to quality and responsibility fosters trust and long-term relationships with clients, who rely on consistently high-performing machines.

Challenges Faced by Pipe Buffing Machine Factories

Despite their crucial role, pipe buffing machine factories face several challenges. One significant issue is the rapid pace of technological change. Keeping up with innovation requires significant investment in research and development. Factories must also consider the increasing demand for automation and smart machinery, which requires skilled labor and ongoing training for employees.

Moreover, the global supply chain can pose challenges, particularly regarding the availability of high-quality raw materials required for machine production. Fluctuations in material costs can impact pricing strategies, affecting competitiveness in the market.

The Future of Pipe Buffing Machine Manufacturing

Looking ahead, the future of pipe buffing machine factories appears bright. The ongoing trends towards automation, artificial intelligence, and Industry 4.0 present exciting opportunities for innovation. Factories that embrace these technologies are likely to enhance efficiency, reduce costs, and improve product offerings.

Additionally, the global push for sustainability will further drive innovations in machine design and processes. The development of eco-friendly materials and practices in manufacturing will become increasingly important to meet both regulatory demands and consumer expectations.

In conclusion, pipe buffing machine factories are vital to the manufacturing ecosystem. They not only provide essential machinery for finishing processes but also drive technological advancements and uphold quality standards. As industries continue to demand higher performance and sustainability, these factories will evolve, ensuring they remain integral to the future of manufacturing.