Understanding Discount Ovality in Centerless Grinders

Centerless grinding is a critical manufacturing process used to enhance the precision of cylindrical components. This method is valued for its ability to produce parts with high accuracy and a superior surface finish without the need for extensive setup time. However, achieving optimal results in centerless grinding is not just about the machine and the right wheels; it's also about understanding specific terms and principles, such as discount ovality.

What is Ovality?

Ovality refers to the deviation of a cylindrical part’s shape from the ideal round form. In an ideal scenario, a cylindrical part should possess a perfect circular cross-section. However, due to various factors in the manufacturing process, the part may develop an oval shape, leading to dimensional inaccuracies. This deviation can affect the performance and functionality of the component, particularly in applications where tight tolerances are critical.

The Concept of Discount Ovality

Discount ovality specifically addresses the reduction of ovality during the grinding process. This term implies that the centerless grinding operation is performed in a manner that significantly minimizes the ovality of the workpiece. Achieving discount ovality is essential for enhancing the quality and performance of cylindrical parts, especially in industries such as automotive, aerospace, and precision engineering where even minute deviations can have profound effects.

Factors Contributing to Ovality

Several factors can contribute to ovality in centerless grinding, including

1. Wheel Alignment The alignment of the grinding wheels is crucial. Any misalignment can lead to uneven grinding pressure, resulting in parts that are not perfectly round.

2. Workpiece Support In centerless grinding, the workpiece is supported by the regulating wheel and often by the work rest blade. Any inconsistencies in support can lead to variations in roundness.

3. Feed Rate The speed at which the workpiece is fed into the grinding wheels can impact the ovality. An inappropriate feed rate may lead to uneven removal of material.

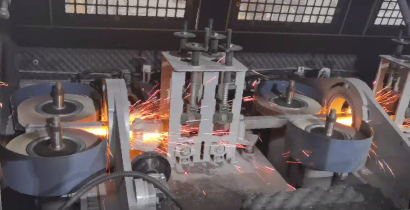

discount ovality in centerless grinder

4. Wheel Condition The condition of the grinding wheels themselves can have a significant impact on the quality of the ground part. Worn-out or improperly dressed wheels can contribute to undesired oval shapes.

5. Coolant Use Coolants play a vital role in the grinding process. Insufficient or improper application can lead to heat buildup, causing thermal expansion and resulting in ovality.

Strategies for Achieving Discount Ovality

To effectively achieve discount ovality in centerless grinding, manufacturers can implement several strategies

1. Regular Maintenance Ensuring that the grinding machine and its components are well-maintained can prevent issues related to wheel alignment and performance. Regular inspection of wheels, bearings, and other components is crucial.

2. Precise Setup Properly setting up the machine is vital. This includes aligning the wheels accurately and ensuring that the workpiece is correctly positioned.

3. Optimal Parameters Identifying and adhering to optimal grinding parameters, like feed rate and wheel speed, can reduce the chances of ovality. Utilizing advanced monitoring systems can help in maintaining these parameters continually throughout operations.

4. Dressing the Wheels Regularly dressing the grinding wheels to maintain their shape and sharpness can enhance their ability to grind accurately and consistently.

5. Implementing Feedback Loops Using feedback mechanisms, where measurements of roundness are taken during the grinding process, can help in making real-time adjustments, thereby minimizing ovality.

Conclusion

Achieving discount ovality in centerless grinding is essential for manufacturing high-quality cylindrical components with precise dimensions. By understanding the factors leading to ovality and adopting strategic practices, manufacturers can significantly improve the roundness of their products. This not only enhances the performance of the parts but also boosts customer satisfaction and reduces waste in the production process. In a competitive marketplace, the pursuit of discount ovality can provide manufacturers with a distinct advantage.