The Best Stainless Steel Pipe Polishing Machines Enhancing Quality and Efficiency

In the world of metalworking, particularly in the fabrication of stainless steel pipes, the finishing process is as important as the cutting and shaping stages. The quality of the final product often depends on the effectiveness of the polishing process. This is where the best stainless steel pipe polishing machines come into play, offering manufacturers the tools they need to achieve a high-quality finish, enhance corrosion resistance, and improve the overall aesthetic appeal of their products.

Understanding Stainless Steel Pipe Polishing

Stainless steel pipes are favored in many industries due to their excellent corrosion resistance, strength, and aesthetic value. However, the natural finish of stainless steel often requires enhancement through polishing. Polishing not only improves the visual appeal of the pipes but also helps in removing imperfections and burrs that can occur during machining. The process can also create a smoother surface that minimizes the adherence of contaminants, thus making the pipe easier to clean and maintain.

Features of Top Polishing Machines

When looking for the best polishing machines for stainless steel pipes, several key features should be considered

1. Versatility Ideal machines should accommodate various pipe diameters and wall thicknesses. The ability to polish different shapes, including round, square, and rectangular pipes, adds significant value.

2. Efficiency High-quality polishing machines should work quickly without sacrificing the quality of the finish. Features like adjustable speed settings allow operators to optimize performance based on the specific requirements of the job.

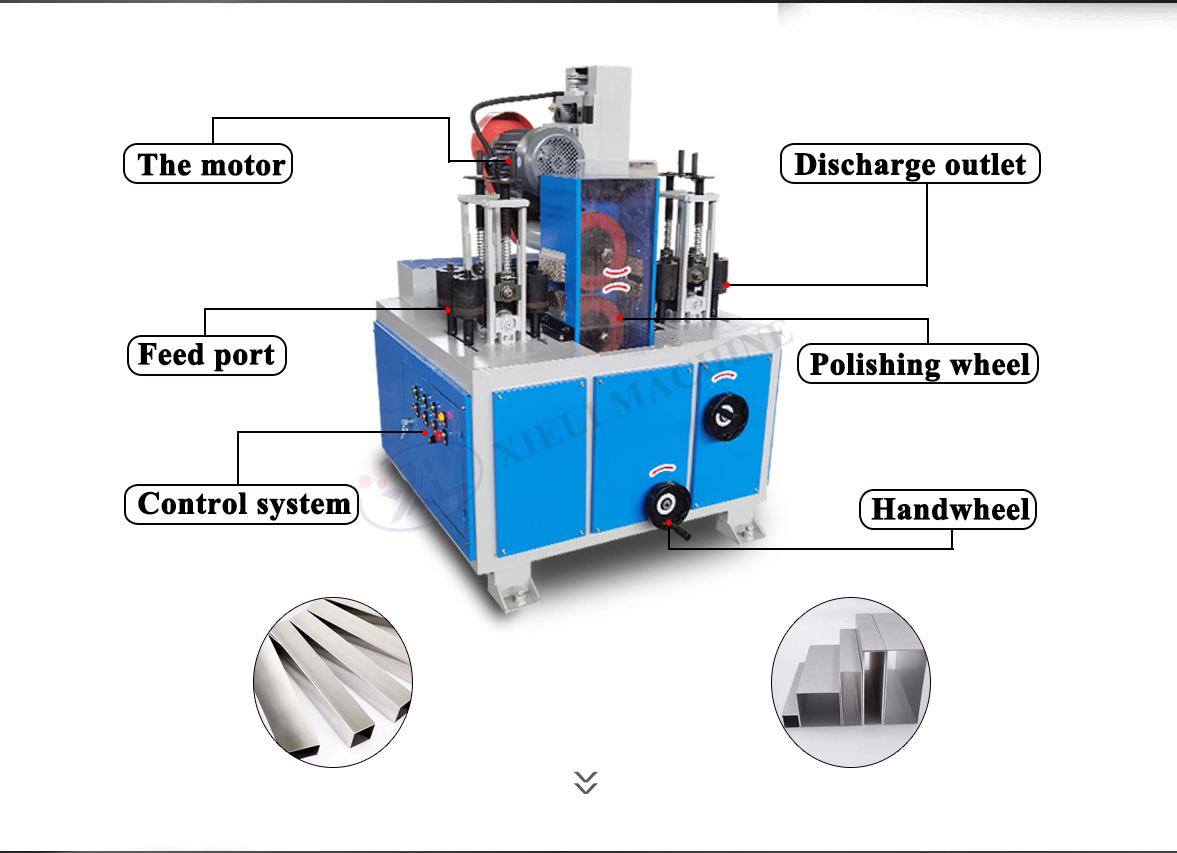

best stainless steel pipe polishing machine

3. Durability Since the polishing process can be demanding, the machines should be constructed from robust materials. This ensures they withstand the rigors of continuous use, providing a long service life.

4. User-Friendly Controls The best machines come with intuitive controls that allow for easy operation, even for inexperienced operators. Digital displays and programmable settings are features that contribute to ease of use.

5. Safety Features Ensuring the safety of operators is paramount. Machines should include safety shields, emergency stop buttons, and other protective features to minimize risks during operation.

The Importance of Technology in Polishing

Modern polishing machines often integrate advanced technology to enhance output quality. For instance, CNC (Computer Numerical Control) machines provide high precision in polishing operations, allowing for consistent results across different batches. Some machines may also employ automated loading and unloading systems, which can significantly increase productivity by reducing downtime between polishing cycles.

Conclusion

Investing in the best stainless steel pipe polishing machine is crucial for manufacturers looking to enhance their product quality and operational efficiency. With the right machine, businesses can ensure that their stainless steel pipes not only meet industry standards but also stand out in terms of appearance and durability. By considering features such as versatility, efficiency, durability, user-friendliness, and safety, manufacturers can select the most appropriate polishing equipment to elevate their production capabilities. As the demand for high-quality stainless steel products continues to grow, the role of advanced polishing machines will become even more critical, driving innovation and excellence in the industry.