Internal Centerless Grinding Machine Manufacturers Pioneering Precision Engineering

In the realm of precision manufacturing, internal centerless grinding machines stand out as essential tools for achieving high tolerances and superior surface finishes in various cylindrical components. The ongoing advancements in grinding technology have bolstered the capabilities of these machines, making them indispensable for industries ranging from automotive to aerospace.

Internal centerless grinding machines operate on a unique principle that eliminates the need for external fixtures. This technique allows for the efficient processing of parts with precise inner diameters and complex geometries. Manufacturers who specialize in producing these machines have leveraged cutting-edge technologies and innovative designs to optimize efficiency and maintain exceptional accuracy.

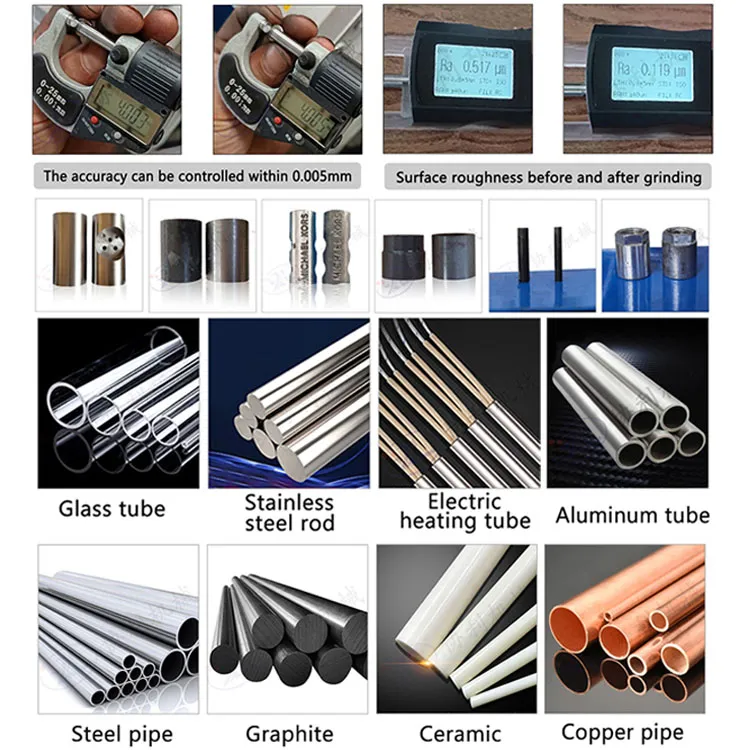

One prominent characteristic of today’s internal centerless grinding machines is their ability to accommodate a wide range of materials

. From hardened steel to ceramic composites, these machines can handle diverse substrates, ensuring that manufacturers can meet varied customer specifications. This versatility has made them particularly attractive to sectors that require stringent quality control and rapid production rates.internal centerless grinding machine manufacturers

The role of manufacturers in this sector is critical, as they are responsible for developing machines that not only improve operational efficiency but also prioritize user safety and ease of maintenance. Leading internal centerless grinding machine manufacturers are now incorporating advanced features such as automated controls, real-time monitoring systems, and user-friendly interfaces. These innovations not only enhance productivity but also reduce the likelihood of operator error and machine downtime.

Furthermore, sustainability is becoming a hot topic within the grinding industry. Manufacturers are increasingly focused on minimizing waste and reducing energy consumption in their machine designs. This aligns with the broader global shift towards environmentally friendly manufacturing practices. The introduction of energy-efficient motors, improved cooling systems, and advanced filtration processes reflects this commitment to sustainability.

As competition intensifies in the global market, manufacturers of internal centerless grinding machines are continuously striving to differentiate themselves. This is achieved through a combination of superior engineering, high-quality materials, and outstanding customer support. By establishing strong relationships with clients, these manufacturers gain valuable insights that inform the development of future products and innovations.

In conclusion, internal centerless grinding machine manufacturers are at the forefront of precision engineering, driving advancements that cater to the evolving needs of various industries. Their commitment to innovation and quality ensures that these machines will continue to play a pivotal role in manufacturing processes worldwide, contributing to enhanced productivity and product excellence.