The Rise of Centerless Grinder Automation Transforming Manufacturing Efficiency

In recent years, the manufacturing industry has undergone a significant transformation, largely driven by advancements in automation technologies. One area that has seen remarkable innovation is the realm of centerless grinding. Centerless grinders have long been a critical component in manufacturing processes, particularly for industries that require high precision and efficiency in the production of cylindrical components. As manufacturers seek to enhance their operational efficiency and reduce production costs, the demand for centerless grinder automation solutions has surged.

Understanding Centerless Grinding

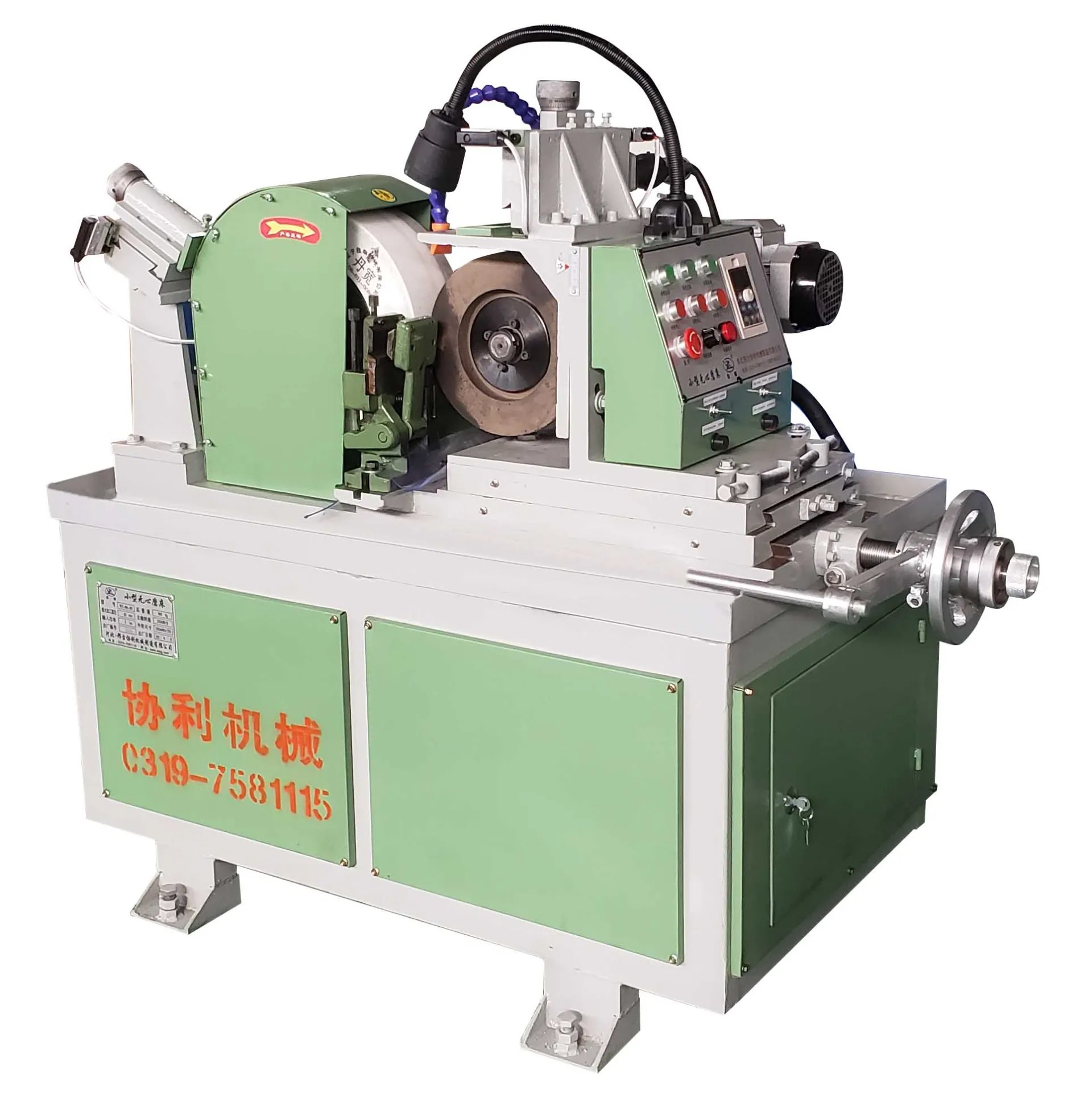

Centerless grinding is a machining process that involves the removal of material from a workpiece to achieve a desired shape and finish without the need for centering the piece. This technique offers several advantages over traditional grinding methods, including higher throughput, reduced cycle times, and enhanced dimensional accuracy. Centerless grinders operate by placing the workpiece between a grinding wheel, a regulating wheel, and a work rest. This configuration allows for continuous operation, making it ideal for mass production settings.

The Need for Automation

As competition intensifies within the manufacturing sector, companies are increasingly pressured to optimize their processes. Automation in centerless grinding presents a solution to several challenges faced by manufacturers. For instance, manual operations often lead to inconsistencies and increased rejection rates due to human error. Automation minimizes these risks by ensuring that grinding processes are executed with precision and repetition. Furthermore, the integration of robotic systems and automated feeding mechanisms significantly boosts productivity by reducing machine idle time and labor costs.

Key Players in Centerless Grinder Automation

A number of manufacturers have emerged as leaders in the development of automated centerless grinding machinery. These companies are leveraging advanced technologies such as artificial intelligence, machine learning, and IoT connectivity to enhance their products. For instance, some machines are equipped with smart sensors that monitor the grinding process in real-time, automatically adjusting parameters to ensure optimal performance. Others incorporate vision systems that perform quality control checks, thereby reducing the need for post-process inspections.

Benefits of Automated Centerless Grinders

1. Increased Productivity Automated centerless grinders can operate continuously, significantly increasing output compared to manual systems. They can also handle multiple parts simultaneously, further enhancing productivity.

centerless grinder automation manufacturers

2. Improved Quality With automated controls and real-time monitoring, manufacturers can achieve higher consistency in part quality. The precision of automated systems reduces the variability typically associated with manual operations.

3. Enhanced Flexibility Modern automated centerless grinders are designed to accommodate various part sizes and shapes, allowing manufacturers to easily switch between different products without extensive retooling.

4. Reduced Labor Costs By minimizing the reliance on manual labor, companies can reduce operational costs while also reallocating human resources to more strategic roles.

5. Increased Safety Automation can help mitigate risks associated with manual grinding processes. With fewer human operators in close proximity to the machinery, the likelihood of workplace accidents diminishes.

Future Trends in Centerless Grinding Automation

As technology continues to evolve, the future of centerless grinder automation appears promising. Innovations such as collaborative robots (cobots) will likely become more prevalent, working alongside human operators to enhance workflow efficiency. Additionally, the integration of digital Twin technologies will allow manufacturers to simulate and optimize grinding processes before implementation, further reducing downtime and waste.

Moreover, the adoption of Industry 4.0 principles will facilitate the interconnectivity of machines and systems, enabling manufacturers to gather and analyze data for continuous improvement. Predictive maintenance powered by AI will help companies foresee potential machine failures, reducing unforeseen downtimes and maintenance costs.

Conclusion

The automation of centerless grinding represents a pivotal shift in manufacturing practices, driving efficiency, quality, and safety. As industry players continue to embrace these advancements, it is evident that the future of manufacturing lies in the integration of intelligent automated systems. By staying ahead of the curve and investing in cutting-edge technology, manufacturers can position themselves for success in an increasingly competitive landscape. Embracing centerless grinder automation is not merely a trend but a necessity for those aiming to thrive in the ever-evolving world of manufacturing.