The Importance of OEM Steel Tube Polishing Machines in Modern Manufacturing

In the fast-evolving landscape of modern manufacturing, the need for precision, quality, and efficiency has never been more critical. At the forefront of this need is the OEM (Original Equipment Manufacturer) steel tube polishing machine, a technology crucial in producing high-quality steel tubes used in various industries, including automotive, aerospace, and construction. This article delves into the significance of these machines, their operational principles, and their contribution to product quality.

Understanding OEM Steel Tube Polishing Machines

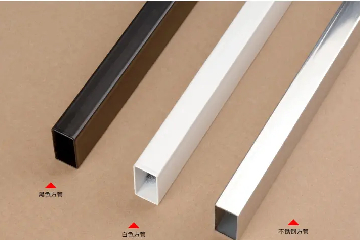

OEM steel tube polishing machines are specialized equipment designed to enhance the surface finish of steel tubes. These machines are tailored to meet specific requirements dictated by the client, ensuring that the polishing process aligns seamlessly with the manufacturing goals. The polishing process typically involves removing imperfections, scaling, and oxidation from the tube surface, resulting in a smoother and more polished finish that is aesthetically appealing and functional.

The primary components of a steel tube polishing machine usually include a polishing head, abrasive materials (such as belts or pads), a feed system, and a control mechanism. The polishing head is where the action happens, as it moves along the length of the tube, applying the abrasive material to achieve the desired finish. The feed system ensures that the tube is moved steadily through the machine, while the control mechanism allows operators to adjust the speed, pressure, and duration of the polishing process, ensuring consistent results across different batch sizes.

Advantages of Using OEM Polishing Machines

1. Customization OEM polishing machines can be designed tailored to specific applications. Manufacturers can work closely with OEM providers to create machines that can handle various tube sizes, materials, and finishes, thus meeting specific industry standards and client needs.

oem steel tube polishing machine

2. Enhanced Product Quality The polishing process not only improves the aesthetic quality of the steel tubes but also enhances their functionality. A smoother surface finish reduces friction during installation and operation, thus extending the lifespan of the tubes and reducing maintenance costs.

3. Increased Efficiency With advancements in technology, modern OEM steel tube polishing machines offer automated solutions that significantly reduce manual labor and associated costs. Automation implies quicker turnaround times, allowing manufacturers to increase production output without compromising quality.

4. Consistency One of the significant advantages of using OEM machines is their ability to maintain uniformity across batches. Consistent polishing ensures that all products meet quality standards, which is crucial for businesses aiming to establish a reputable brand in competitive markets.

5. Environmental Considerations Many modern polishing machines are designed with eco-efficiency in mind. They use advanced filtering and recycling systems to minimize waste produced during the polishing process, making them a more sustainable choice for manufacturers.

Conclusion

In summary, OEM steel tube polishing machines represent a vital aspect of contemporary manufacturing processes. Their ability to produce high-quality, polished steel tubes is essential across various industries where reliability and performance are paramount. As manufacturers face increasing demands for precision and efficiency, investing in OEM polishing solutions becomes not just beneficial but necessary for maintaining a competitive edge in today’s market. With ongoing technological advancements, these machines are poised to evolve further, enhancing their capabilities and meeting the ever-changing needs of the manufacturing sector.