In the realm of industrial manufacturing, the quest for superior finishing techniques is paramount. Within this context, the inner wall polishing machine stands as an essential tool that significantly enhances the quality and efficiency of production processes. These machines, which focus on the intricate polishing of inner surfaces, play a crucial role in industries ranging from automotive to aerospace, where precision and smoothness are imperative.

Users with firsthand experience with these machines often highlight their impressive capabilities in refining inner surfaces to a mirror-like finish. This superior finish is not only visually appealing but also crucial for ensuring optimal performance and longevity of various mechanical components. For example, in the aerospace industry, the inner surfaces of components such as cylinders and conduits require a high degree of finish to minimize friction and wear, thereby enhancing the efficiency of airflow and other mechanical processes.

Professionals emphasize the importance of selecting the right machine based on specific operational needs. The spectrum of inner wall polishing machines varies from manual devices to fully automated systems that integrate with existing production lines. Experts with extensive knowledge in this domain often recommend machines that feature adjustable speed settings and various abrasive media, which allow businesses to tailor the polishing process according to material types and desired finish levels. Such versatility not only bolsters the machine's applicability across diverse tasks but also extends its service life, providing a cost-effective solution for businesses.

Authoritative sources underscore the significance of regular service and maintenance regimes to ensure the prolonged efficiency and accuracy of these machines. Routine checks and timely replacement of worn parts, such as belts and polishing heads, are vital in maintaining optimal operational conditions. Neglecting these aspects can lead to subpar finishes and increased downtime, ultimately affecting a company’s bottom line. Service providers with specialized training offer invaluable services, ensuring that each machine operates at peak performance. They bring an in-depth understanding of the machine's intricacies, recommending best practices tailored to the specific needs of each manufacturing environment.

inner wall polishing machine service

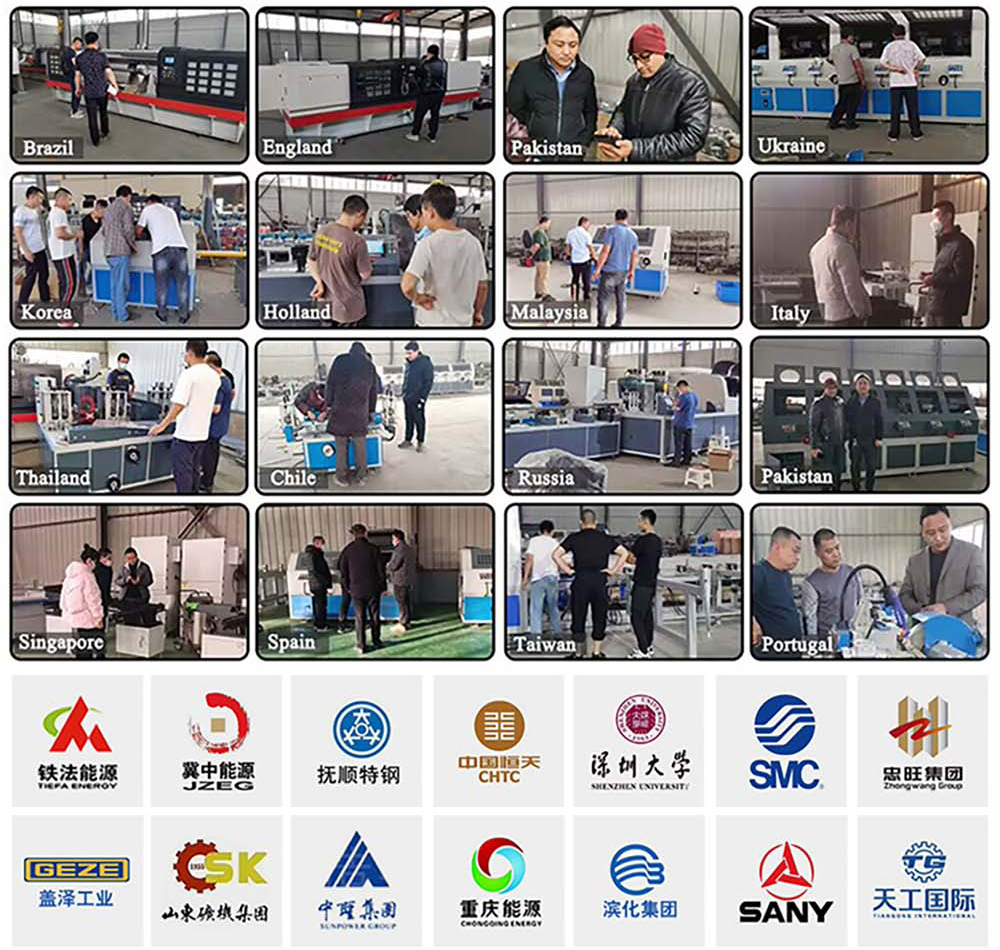

Trustworthiness in service provision is thus a key consideration for businesses relying on inner wall polishing machines. It is recommended to partner with service providers who not only possess significant industry experience but also maintain a transparent service record. Accreditation from recognized industry bodies often serves as a reliable indicator of quality. Furthermore, testimonials and case studies from other industrial entities can provide additional reassurances regarding the reliability and expertise of service providers.

Incorporating digital innovations into these machines further elevates their effectiveness. Advanced models now boast features such as IoT integration, allowing for real-time monitoring and predictive maintenance. This feature reduces unexpected breakdowns and assists in planning service schedules, thereby maximizing machine uptime. Additionally, some advanced machines come equipped with AI-powered systems that adapt the polishing process based on real-time feedback, ensuring unparalleled consistency and quality in finishes.

Investing in an inner wall polishing machine is a strategic decision for any manufacturing entity aiming to enhance production capability and product quality. By aligning with expert service providers and embracing technological advancements, businesses can significantly optimize their operational efficiency. Such strategic moves not only improve product attractiveness but also engender trust among clients and partners, positioning the business as a leader within its industry.

In conclusion,

the inner wall polishing machine is not just a tool but a pivotal component in the precision manufacturing landscape. With a focus on continuous improvement through expert service and cutting-edge technology, businesses can assure their place at the forefront of innovation, delivering impeccable products that stand the test of time.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.