Februari . 15, 2025 19:47

Back to list

inner wall polishing machine service

In the realm of industrial manufacturing, the quest for superior finishing techniques is paramount. Within this context, the inner wall polishing machine stands as an essential tool that significantly enhances the quality and efficiency of production processes. These machines, which focus on the intricate polishing of inner surfaces, play a crucial role in industries ranging from automotive to aerospace, where precision and smoothness are imperative.

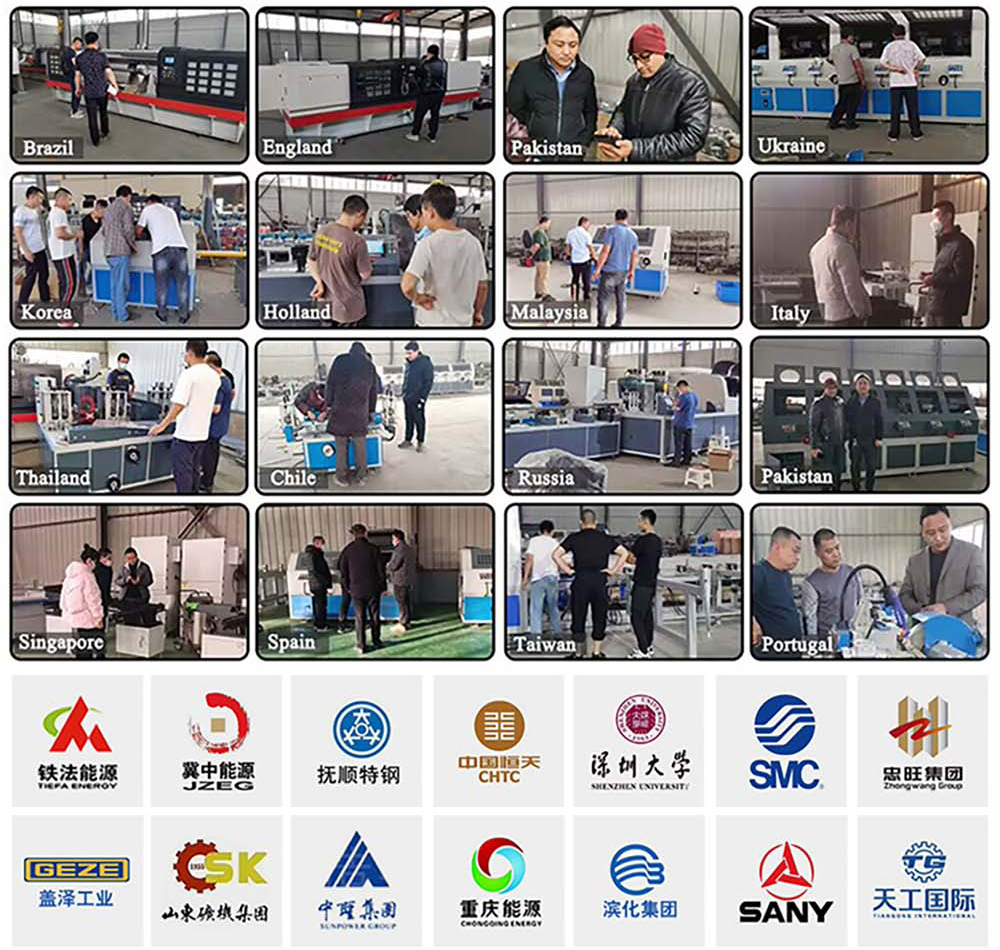

Trustworthiness in service provision is thus a key consideration for businesses relying on inner wall polishing machines. It is recommended to partner with service providers who not only possess significant industry experience but also maintain a transparent service record. Accreditation from recognized industry bodies often serves as a reliable indicator of quality. Furthermore, testimonials and case studies from other industrial entities can provide additional reassurances regarding the reliability and expertise of service providers. Incorporating digital innovations into these machines further elevates their effectiveness. Advanced models now boast features such as IoT integration, allowing for real-time monitoring and predictive maintenance. This feature reduces unexpected breakdowns and assists in planning service schedules, thereby maximizing machine uptime. Additionally, some advanced machines come equipped with AI-powered systems that adapt the polishing process based on real-time feedback, ensuring unparalleled consistency and quality in finishes. Investing in an inner wall polishing machine is a strategic decision for any manufacturing entity aiming to enhance production capability and product quality. By aligning with expert service providers and embracing technological advancements, businesses can significantly optimize their operational efficiency. Such strategic moves not only improve product attractiveness but also engender trust among clients and partners, positioning the business as a leader within its industry. In conclusion, the inner wall polishing machine is not just a tool but a pivotal component in the precision manufacturing landscape. With a focus on continuous improvement through expert service and cutting-edge technology, businesses can assure their place at the forefront of innovation, delivering impeccable products that stand the test of time.

Trustworthiness in service provision is thus a key consideration for businesses relying on inner wall polishing machines. It is recommended to partner with service providers who not only possess significant industry experience but also maintain a transparent service record. Accreditation from recognized industry bodies often serves as a reliable indicator of quality. Furthermore, testimonials and case studies from other industrial entities can provide additional reassurances regarding the reliability and expertise of service providers. Incorporating digital innovations into these machines further elevates their effectiveness. Advanced models now boast features such as IoT integration, allowing for real-time monitoring and predictive maintenance. This feature reduces unexpected breakdowns and assists in planning service schedules, thereby maximizing machine uptime. Additionally, some advanced machines come equipped with AI-powered systems that adapt the polishing process based on real-time feedback, ensuring unparalleled consistency and quality in finishes. Investing in an inner wall polishing machine is a strategic decision for any manufacturing entity aiming to enhance production capability and product quality. By aligning with expert service providers and embracing technological advancements, businesses can significantly optimize their operational efficiency. Such strategic moves not only improve product attractiveness but also engender trust among clients and partners, positioning the business as a leader within its industry. In conclusion, the inner wall polishing machine is not just a tool but a pivotal component in the precision manufacturing landscape. With a focus on continuous improvement through expert service and cutting-edge technology, businesses can assure their place at the forefront of innovation, delivering impeccable products that stand the test of time.

Latest news

-

Premium Centerless Grinder Coolant OEM Solutions & China SupplierNewsMay.18,2025

-

High-Efficiency Pipe Inside Polishing Machine OEM & China SupplierNewsMay.18,2025

-

Sanworld Steel Tube Polishing Machine - OEM Precision & DurabilityNewsMay.18,2025

-

Top-Rated CNC Centerless Grinder Suppliers High Precision & Custom SolutionsNewsMay.17,2025

-

Precision Pipe Grinding Machines High-Efficiency & Discount Deals in ChinaNewsMay.17,2025

-

Precision CNC Centerless Grinders for Sale OEM & Bulk DealsNewsMay.17,2025