In modern manufacturing environments, precision and efficiency are the twin engines driving competitive advantage. Whether it’s for automotive parts, architectural fixtures, or medical components, achieving a flawless metal finish is no longer just an aesthetic consideration—it’s a fundamental performance requirement. Industrial-grade polishing machinery plays a crucial role in ensuring that raw or semi-finished metal surfaces meet the required standards of smoothness, reflectivity, and uniformity. Among the most indispensable tools in this space are pipe surface polisher and sheet polishing machines, tailored to handle various material types, shapes, and application needs across high-demand sectors.

Enhancing Cylindrical Surface Finish with a Pipe Surface Polisher in High-Volume Operations

In sectors where stainless steel tubes, alloy pipes, or cylindrical bars are mass-produced, manufacturers often integrate a pipe surface polisher into their assembly line. These machines are engineered to deliver consistent surface textures across lengths of pipe, reducing manual labor and eliminating inconsistencies caused by human error. The use of multi-head abrasive belts and adjustable pressure settings ensures precise control over material removal rates. Moreover, the pipe polisher enhances downstream processing by removing imperfections that could compromise welding, coating, or sealing performance. This level of refinement is especially critical in oil and gas, food-grade piping, and pharmaceutical tubing applications.

Industrial Applications Benefit from the Stainless Steel Sheet Polishing Machine in Productivity and Finish

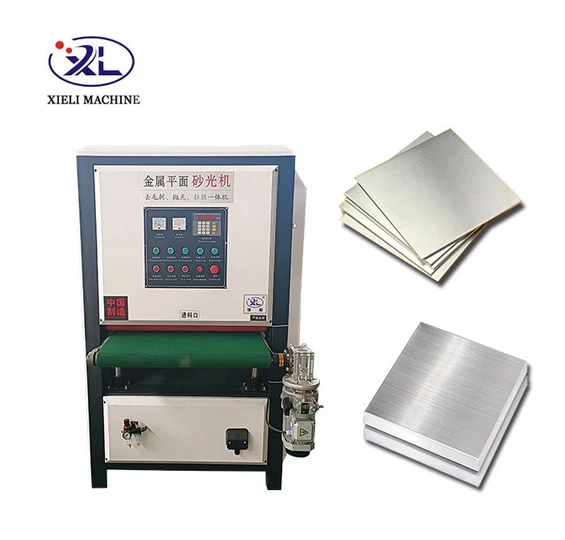

When working with flat surfaces such as panels, brackets, and enclosure covers, a stainless steel sheet polishing machine becomes a core asset in the fabrication line. Positioned after cutting and forming stages, these machines deliver uniform, scratch-free surfaces that comply with industry-specific standards like ASTM or ISO for metal finishing. Not only does a stainless steel sheet polishing machine minimize processing time, but it also ensures tight tolerances on finish depth and texture, especially when products must meet sanitary or decorative expectations. Manufacturers in the kitchen equipment, elevator, and pharmaceutical industries regularly use these machines to enhance both appearance and hygiene standards.

Using a Sheet Metal Polishing Machine to Standardize Surface Quality Across Large Workpieces

Large-format or irregularly shaped metal sheets present unique challenges for surface treatment. A sheet metal polishing machine tackles this complexity by utilizing variable-speed rollers, automated brushing systems, and intelligent feedback controls. These features enable consistent polishing even on oversized or asymmetrical sheet metal components. In industries such as aerospace or heavy machinery, surface uniformity on critical components can influence not only appearance but also functionality and wear resistance. By adopting a sheet metal polishing machine, factories can standardize their production outputs, reduce post-processing defects, and enhance operational efficiency.

Delivering Mirror Finishes with Precision Using an SS Sheet Buffing Machine in Professional Fabrication

A high-gloss or mirror-like finish is often required in architectural panels, automotive trim, and decorative hardware. Achieving such finishes requires the advanced performance of an ss sheet buffing machine, which utilizes multi-stage buffing pads, polishing waxes, and micro-abrasives. These machines ensure optimal results without over-heating or distorting the thin stainless steel surfaces. Additionally, the ss sheet buffing machine is designed with integrated cooling and dust collection systems, making it a safe and clean solution for factories where environmental and operator safety regulations are strictly enforced. This machine is essential when a flawless reflective finish is not just preferred—but required.

Leveraging SS Sheet Polishing Machine Technology for Long-Term Operational Savings

Reducing operational downtime and material waste is a top priority in metalworking plants, and the ss sheet polishing machine plays a vital role in achieving this goal. Unlike manual grinding or polishing methods, these machines offer repeatable, programmable cycles that eliminate variability and boost throughput. The integration of digital controllers and automatic abrasive replenishment systems allows operators to manage large production runs with minimal supervision. Over time, the efficiency gains from using an ss sheet polishing machine translate into tangible savings in labor, energy consumption, and scrap reduction, making it an essential investment for industrial-scale production facilities.

Key Features to Look for in Industrial Polishing Equipment

When selecting polishing machinery for industrial use, critical features include automated feed mechanisms, adjustable pressure settings, integrated dust extraction systems, and compatibility with different abrasives. High-quality machines also provide programmable logic controllers (PLCs) for process automation and safety interlocks for operator protection.

Maintenance Considerations for Sheet and Pipe Polishers

Regular maintenance is essential to maintain performance. This includes replacing worn abrasives, checking for motor alignment, inspecting belts, and cleaning dust filters. Most modern machines come with diagnostic tools that alert operators to maintenance needs before failures occur.

Common Industrial Applications for Polishing Equipment

Applications include preparing stainless steel surfaces for laser welding, enhancing reflectivity for solar panel components, smoothing sharp edges on fabricated enclosures, and polishing food-processing equipment to meet hygiene standards.

Pipe Surface Polisher and Sheet Polishing Machines FAQs

Q: What industries benefit the most from using a pipe surface polisher?

A: Industries such as plumbing, aerospace, pharmaceuticals, and oil and gas rely on these machines to ensure uniform, contamination-free pipe surfaces suitable for high-performance applications.

Q: How does a stainless steel sheet polishing machine improve efficiency in metal fabrication?

A: It automates the polishing process, delivers consistent results, and reduces labor costs, while also enhancing the final product’s aesthetics and performance characteristics.

Q: Is a sheet metal polishing machine suitable for all metal types?

A: While primarily designed for stainless steel, many machines can be adjusted to work on aluminum, brass, and other alloys with proper abrasive selection.

Q: What’s the difference between an ss sheet buffing machine and a polishing machine?

A: Buffing machines focus on creating ultra-smooth or mirror finishes using soft abrasives and polishing compounds, whereas polishing machines typically use coarser abrasives for initial surface leveling and smoothing.

Q: How long does it take to replace abrasives on an ss sheet polishing machine?

A: Most systems are designed for quick-change operation, with replacement typically taking 10–15 minutes, minimizing downtime during large-scale production cycles.