In the industrial sector, precision and presentation are critical—not just for aesthetic appeal but also for performance, safety, and durability. Surface finishing plays a major role in these areas, and that’s where polishing machines come into the picture. Whether working with wood or metal, the right equipment can dramatically improve productivity, product lifespan, and overall quality. Understanding the range and investment value of these machines—such as the wood polish machine price, types of surface polishers, and their specific industrial functions—is vital for manufacturers and workshop operators.

Advanced Equipment Drives Efficiency When Considering Wood Buffing Machine Price

In industries dealing with large volumes of wood-based components, finishing machines are not a luxury—they’re a necessity. While some may initially hesitate over the wood buffing machine price, the cost is often quickly offset by gains in labor efficiency, surface consistency, and reduced waste. These machines are engineered to handle heavy-duty tasks like smoothing uneven textures, removing micro-imperfections, and enhancing the natural grain appearance of the wood. In environments such as furniture manufacturing, cabinetry production, and timber construction, investing in a high-quality buffing unit leads to measurable improvements in output and quality control.

Achieving High-Precision Finishes with the Right Surface Polishing Machine

Precision is the currency of modern industry, and few tools deliver it better than a reliable surface polishing machine. Rather than performing repetitive manual labor, operators can rely on these machines to automate surface refinement at scale. Whether it’s preparing wood panels for coating or refining composite materials used in interiors or equipment housing, surface polishers help maintain consistent standards. One of the strongest industrial benefits lies in how these machines eliminate human error in repetitive sanding or polishing tasks, thereby ensuring uniformity in gloss, smoothness, and edge rounding across batches of production.

Redefining Quality Standards with a Metal Surface Polishing Machine in Industrial Lines

Heavy-duty industries—such as automotive, aerospace, or fabrication—require a seamless finish for both performance and compliance purposes. Investing in a metal surface polishing machine elevates a manufacturer’s ability to meet these demands. Mid-sized operations benefit from improved turnaround times, while larger manufacturers see stronger returns on consistency and precision. These machines are optimized to handle stainless steel, aluminum, brass, and other alloys, ensuring that every component emerges burr-free and ready for final assembly or coating. The return on investment is evident not only in visual results but also in improved bonding properties and corrosion resistance of treated surfaces

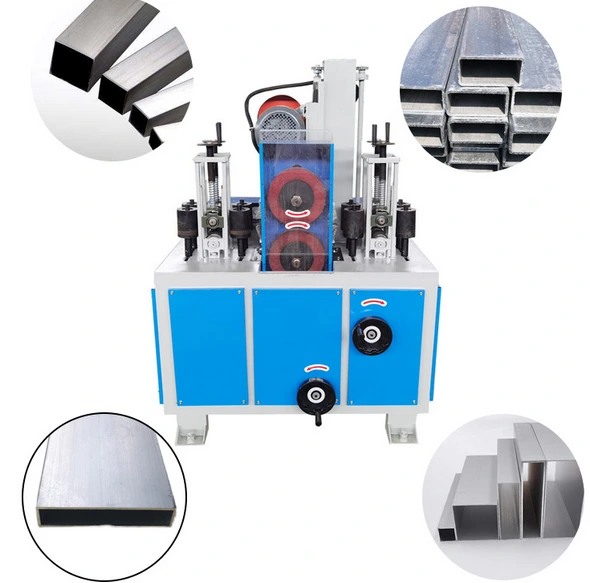

Flat Surface Polishing Machine Enhances Production in Panel and Sheet Industries

In fabrication environments that rely heavily on panel structures or flat material profiles, the flat surface polishing machine is indispensable. Whether polishing engineered wood panels, composite board surfaces, or metallic sheets, these machines bring an unmatched uniformity to the final product. They’re particularly valuable in the production of wall cladding, metal facades, and furniture panels where visible surfaces must meet stringent aesthetic and tactile quality benchmarks. Industrial workshops gain speed and precision while ensuring surface smoothness, crucial for applying films, laminates, or protective coatings.

Versatility and Automation for Mass Production

Across both wood and metal sectors, polishing machinery supports not just surface improvement but also overall workflow automation. Conveyor systems, variable speed settings, dust extraction units, and programmable pressure settings all help tailor operations to unique product types. This adaptability means that one setup can often serve multiple product lines, maximizing investment value.

Reducing Operational Downtime through Quality Machinery

Durability and minimal maintenance are key reasons why industries choose well-engineered polishers. Machines with high thermal stability and advanced motor technologies operate longer under high loads without risk of breakdowns, minimizing costly interruptions in production.

Safety and Compliance in Industrial Surface Treatment

Industrial safety protocols increasingly prioritize dust suppression and operator ergonomics. Modern polishing systems are designed with enclosure systems, efficient debris collection, and low-noise operation, aligning with occupational health standards without compromising performance.

Industrial Polishing Machines FAQs

Q: What factors affect the wood polish machine price in industrial applications?

A: Pricing typically depends on machine size, automation level, power rating, and the number of working heads. Heavy-duty models with programmable settings and integrated dust collectors are more expensive but offer long-term operational benefits.

Q: How does the wood buffing machine price compare to manual polishing costs?

A: While the wood buffing machine price may seem high upfront, automated systems significantly reduce labor costs, increase throughput, and ensure a consistent finish—making them more economical in the long run.

Q: Are surface polishing machines suitable for both wood and metal materials?

A: Some universal models support interchangeable heads and pressure settings for different materials. However, dedicated metal surface polishing machines are recommended for harder alloys, while wood applications benefit from more delicate buffer configurations.

Q: What are the maintenance requirements for a flat surface polishing machine?

A: Regular cleaning of abrasive belts or pads, lubrication of moving parts, and inspection of electrical components are essential to ensure smooth operation and extend machine lifespan.

Q: How can I select the right polishing machine for my industrial needs?

A: Start by assessing the material type, production volume, desired finish quality, and available space. Then compare technical specs such as motor power, feed speed, and adjustable pressure to ensure the equipment aligns with your production demands.