Understanding the Polishing Belt Machine A Essential Tool in Surface Finishing

In the realm of manufacturing and metal finishing, the polishing belt machine plays a pivotal role in achieving high-quality surface finishes. This versatile tool is designed to enhance the aesthetics and functionality of various materials, including metals, plastics, and composites. In this article, we will explore the features, benefits, and applications of polishing belt machines, highlighting their significance in various industries.

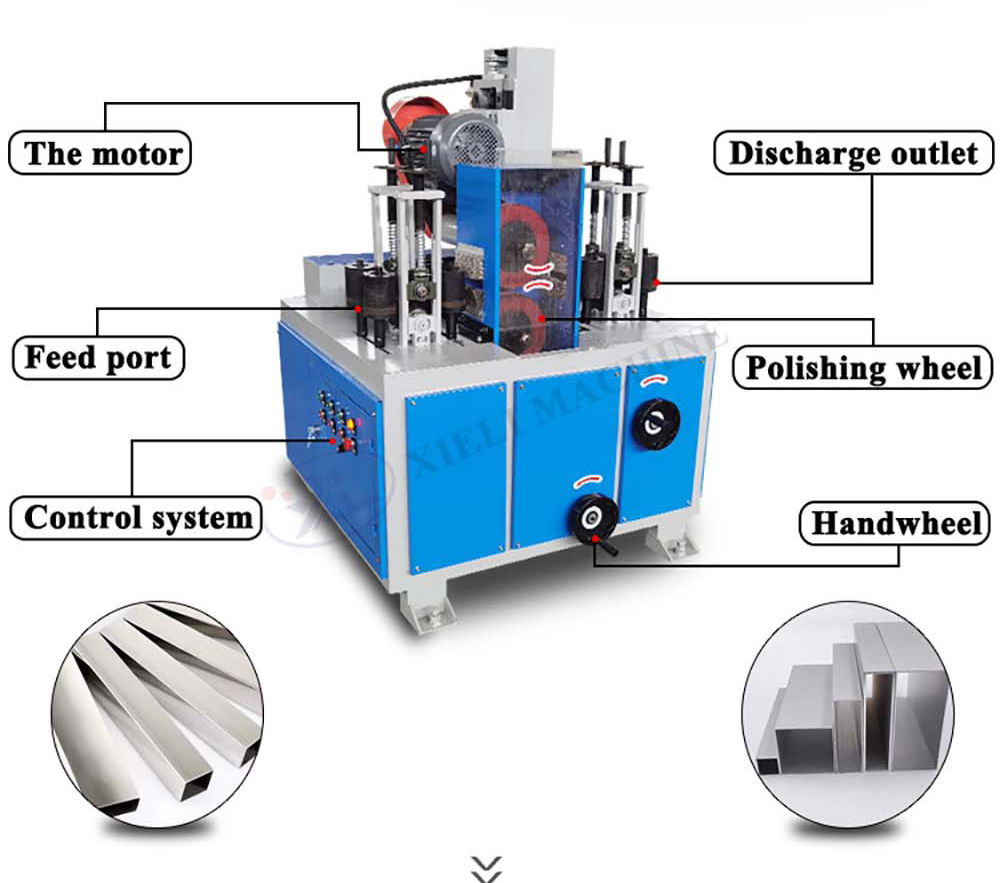

What is a Polishing Belt Machine?

A polishing belt machine is specifically engineered to smooth, polish, and prepare surfaces for further treatment or final use. It utilizes an abrasive belt made of various materials, including cloth, paper, or synthetic compounds, to abrade the workpiece surface. The operation typically involves moving the workpiece against a moving belt, which is powered by a motor. The contact between the belt and the surface removes imperfections, such as scratches, oxidation, and debris, resulting in a polished finish.

Key Features

1. Versatility Polishing belt machines are available in various sizes and configurations, making them suitable for different applications. Whether it is for small parts or large components, there exists a model tailored to meet specific requirements.

2. Adjustable Speed Many machines come with adjustable speed settings, allowing operators to choose the optimal speed according to the material being polished and the desired finish. This feature enhances control and consistency in the polishing process.

3. Ease of Use Modern polishing belt machines are designed with user-friendliness in mind. Features such as digital displays, automatic tensioning systems, and easy belt replacement mechanisms make operation straightforward, minimizing the learning curve for new users.

4. Durability Constructed from robust materials, polishing belt machines are built to withstand continuous operation. The quality of the components ensures longevity and reliable performance over time.

Benefits of Using a Polishing Belt Machine

polishing belt machine

1. Quality Finish The primary advantage of a polishing belt machine is its ability to produce a superior finish that enhances the aesthetic appeal and functionality of products. A well-polished surface is not only visually appealing but also resistant to corrosion and wear.

2. Increased Efficiency Compared to manual polishing methods, these machines significantly speed up the finishing process. This efficiency translates to higher productivity and reduced labor costs, which are critical factors for businesses looking to optimize operations.

3. Consistency Machines provide uniform results, ensuring that every product meets the desired specifications. This consistency is particularly important in industries where precision and quality control are paramount.

4. Reduced Waste With precise control over the polishing process, there is less material waste compared to traditional methods. This not only leads to cost savings but also contributes to sustainability practices in manufacturing.

Applications of Polishing Belt Machines

Polishing belt machines find application in various industries, including

- Metalworking Used for polishing metal components, such as automotive parts, hardware, and decorative items. - Woodworking Effective in finishing wooden surfaces to create smooth, elegant finishes on furniture and cabinetry. - Plastic and Composites Manufacturing Ideal for refining plastic parts and composite materials, enhancing their appearance and performance.

- Jewelry Making Essential in the jewelry industry for achieving lustrous finishes on precious metals and gemstones.

Conclusion

In summary, the polishing belt machine is an indispensable tool in achieving high-quality finishes across a broad spectrum of materials and industries. Its versatility, efficiency, and ability to deliver consistent results make it a favored choice among manufacturers and craftsmen. As technology advances, we can expect further enhancements in the design and functionality of these machines, solidifying their place in the future of surface finishing processes. Whether for industrial use or artisanal applications, the polishing belt machine stands out as a key instrument in transforming rough materials into polished masterpieces.