Understanding Centerless Grinding Machines and Their Pricing

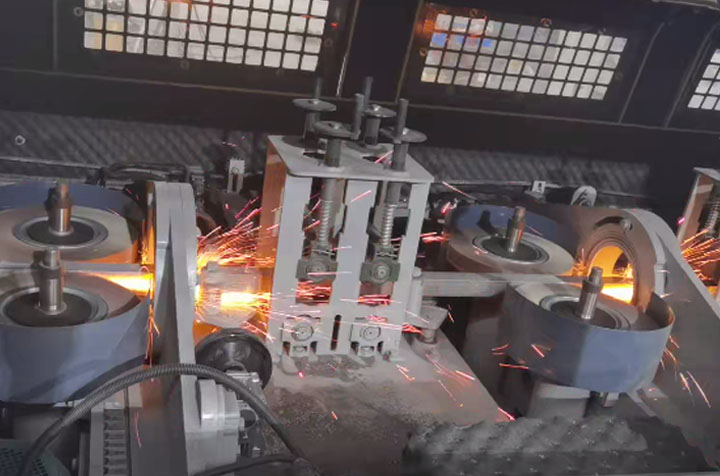

Centerless grinding machines are essential tools in the manufacturing industry, specifically in processes that require precision and efficiency. Unlike traditional grinding machines, which require the workpiece to be held in place by fixtures, centerless grinding uses a set of wheels to allow the material to be supported only at its ends. This method offers several advantages, including increased speed, greater efficiency, and the ability to grind longer workpieces.

Key Features of Centerless Grinding Machines

Before diving into the price range and factors affecting their cost, it’s important to understand the key features that generally come with centerless grinding machines. These machines are designed to handle various operations such as in-feed grinding, through-feed grinding, and above all, for producing high-precision cylindrical parts. Typical features might include

1. Adjustable Wheel Setup Centerless grinders often have adjustable wheels that can accommodate different part sizes. 2. Durable Construction Many machines are built with robust materials to ensure longevity and robustness under continuous operations. 3. Advanced Technology Modern centerless grinders may come equipped with CNC capabilities, allowing for higher precision and automated processes.

Pricing Overview

The price of centerless grinding machines varies significantly depending on several factors, including brand, specifications, and whether the machine is new or used. Generally, prices can range from a few thousand dollars for a basic used model to several hundred thousand dollars for high-end, feature-rich machines.

centerless grinding machine price pricelist

1. Entry-Level Machines Basic centerless grinding machines may start at around $10,000 to $25,000. These machines often provide the essential features required for small-scale operations or new businesses. 2. Mid-Range Options Mid-tier machines can range from $25,000 to $75,000. These models typically incorporate more features and technologies, offering better performance and precision, making them suitable for larger businesses with more complex grinding needs.

3. High-End Machines High-precision centerless grinders designed for industrial applications can exceed $100,000. These machines often incorporate advanced CNC technology, automation systems, and specialized features to handle intricate tasks more efficiently.

Factors Influencing Price

Several factors contribute to the pricing of centerless grinding machines

- Brand Reputation Established manufacturers often charge a premium for their machines due to a history of reliability and superior customer service. - Technology Level Machines with advanced controls, automation, and precise sensors will typically be priced higher than simpler models. - Machine Condition The condition of the machine (new vs. used) significantly impacts its price. While used machines can be more economical, they may come with risks related to maintenance and potential repairs. - Customization Customized machines that are tailored for specific applications generally come at a higher price due to the additional design and engineering work involved.

Conclusion

Investing in a centerless grinding machine is a critical decision for any manufacturing operation. While the variety of price points offers options for businesses of all sizes, it’s vital to consider the machine’s features, capabilities, and the specific grinding applications required. By carefully evaluating these factors, companies can make informed decisions that align with their operational needs and budget constraints. Whether for small-scale production or high-volume manufacturing, understanding the centerless grinding machine market is essential for optimizing production efficiency and quality.