The Importance of Polishing Belt Machine Services

In the modern manufacturing landscape, precision and quality are paramount. Industries across the board rely on various machinery and equipment to ensure their products meet stringent standards. One such vital piece of equipment is the polishing belt machine. These machines play an essential role in enhancing the surface finish of materials, providing the sleek, refined appearance that consumers expect. However, like any machinery, they require regular maintenance and servicing to operate effectively. This article explores the significance of polishing belt machine services and how they contribute to operational efficiency.

Understanding Polishing Belt Machines

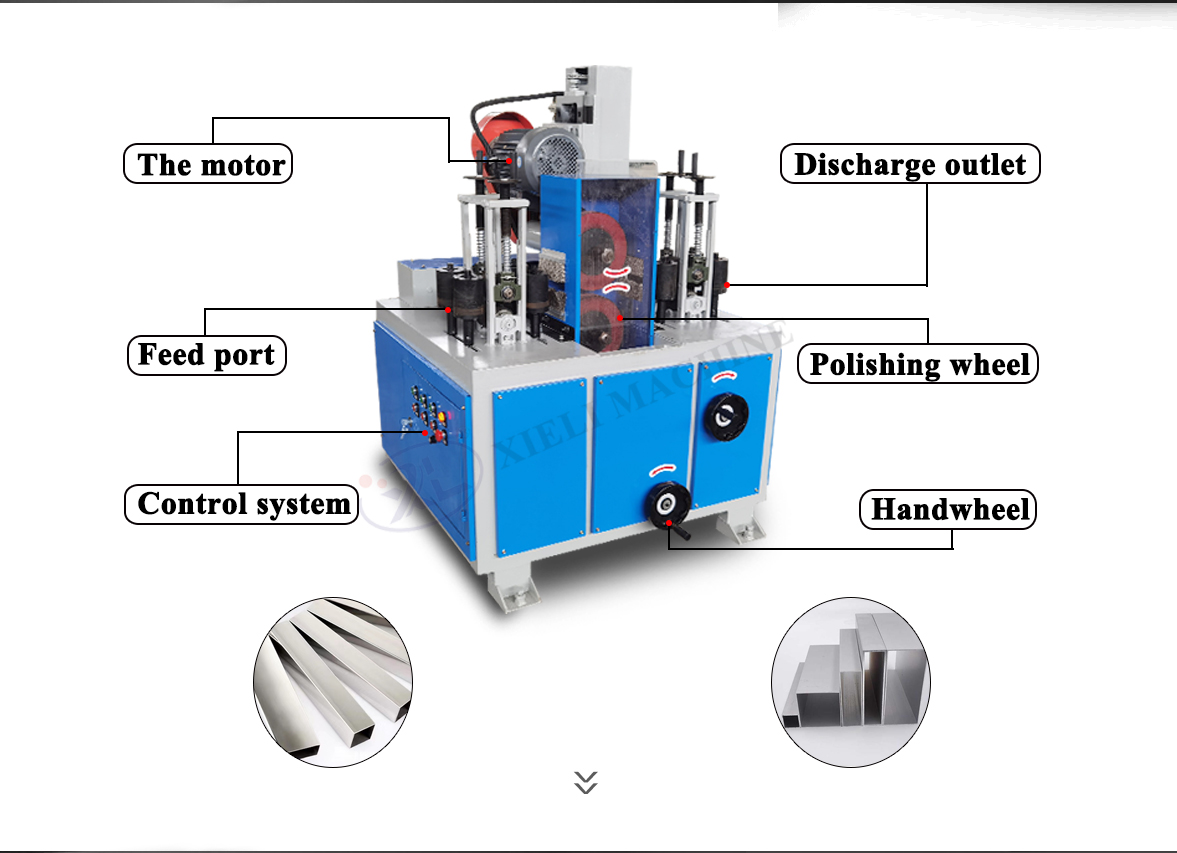

Polishing belt machines are designed to polish and finish surfaces using abrasive belts. They can be used on various materials, including metals, plastics, and wood, making them versatile tools in manufacturing sectors such as automotive, aerospace, and furniture production. The primary function of these machines is to remove imperfections, scratches, and oxidation from surfaces, thereby producing a smooth and aesthetically pleasing finish.

The Need for Regular Service

Just like any machinery, polishing belt machines experience wear and tear over time. Regular servicing is crucial to ensure they function optimally. Neglecting maintenance can lead to several issues, including reduced performance, increased downtime, and even costly repairs or replacements. Servicing involves inspecting the belts, motors, and other components for signs of wear and tear, ensuring that everything operates smoothly.

Regular service checks are also essential for identifying potential problems before they escalate. For instance, if a belt shows signs of excessive wear, it can be replaced proactively, avoiding interruptions in production. Additionally, cleaning and calibrating the machine contribute to more uniform polishing results, which enhance product quality.

Benefits of Professional Services

polishing belt machine service

Engaging professional services for polishing belt machines offers numerous advantages. Trained technicians possess the expertise to diagnose issues accurately and perform necessary repairs efficiently. They understand the intricacies of various models and can provide tailored services to fit specific needs.

Moreover, professional servicing can enhance the lifespan of the machine. By using the right techniques and quality replacement parts, service providers can help maintain the machine's efficiency and longevity. This proactive approach not only saves costs in the long run but also ensures that production remains uninterrupted.

Cost-Efficiency and Productivity

Investing in polishing belt machine services can lead to significant cost savings. Well-maintained machines consume less energy and operate more efficiently, which directly impacts production costs. Furthermore, reliable machinery leads to increased productivity. With less time spent on repairs and more time in operation, businesses can meet production deadlines more effectively.

Additionally, high-quality polished finishes reduce the need for rework or touch-ups on products, saving valuable time and resources. Finally, consistent quality builds customer trust and satisfaction, further enhancing a company’s reputation in the industry.

Conclusion

In conclusion, polishing belt machine services are an indispensable aspect of modern manufacturing. They ensure that these essential tools operate at peak performance, delivering the high-quality finishes that consumers demand. Regular maintenance, conducted by professionals, not only enhances the efficiency and longevity of the machines but also contributes to overall cost savings and improved productivity. To thrive in a competitive marketplace, businesses must prioritize the servicing of their polishing belt machines and recognize the value these services bring to their operations.