The Evolution and Significance of China’s Centerless Grinder Machines

In the modern manufacturing landscape, the demand for precision and efficiency has propelled the development of various machining technologies. Among these, centerless grinding stands out as a vital process for shaping and finishing workpieces in various industries. China has emerged as a significant player in this field, producing advanced centerless grinding machines that cater to the diverse needs of both domestic and international markets.

What is Centerless Grinding?

Centerless grinding is a machining process that removes material from a workpiece without the need for centering the object. Instead of using a fixed spindle to hold the workpiece, the centerless grinder uses two wheels a grinding wheel and a regulating wheel. The grinding wheel, positioned above the workpiece, removes material as the object is fed through the machine. The regulating wheel controls the speed of the workpiece's movement and keeps it aligned throughout the grinding process. This method offers several advantages, including higher productivity, tighter tolerances, and the ability to process long and slender parts efficiently.

The Growth of Centerless Grinder Manufacturing in China

China's centerless grinder machine manufacturing sector has seen remarkable growth over the past few decades. With the country's rapid industrialization and technological advancements, Chinese manufacturers have been able to combine traditional craftsmanship with modern technology. They have invested heavily in research and development to innovate and refine their products, ensuring that they meet international standards.

Today, Chinese centerless grinders are known for their reliability, precision, and cost-effectiveness. Manufacturers, such as Jainnher Machine Co., Ltd., have gained recognition for offering a wide range of centerless grinding machines that serve various applications, from automotive components to precision engineering parts. The ability to customize these machines has also allowed manufacturers to cater to specific customer requirements, enhancing their competitiveness in global markets.

Key Advantages of Chinese Centerless Grinder Machines

1. Cost-Effectiveness One of the most significant advantages of Chinese centerless grinding machines is their affordability. Chinese manufacturers can produce high-quality machines at lower prices compared to their counterparts in Western countries. This cost advantage is particularly appealing to small and medium-sized enterprises that are looking to invest in efficient machining solutions without breaking the bank.

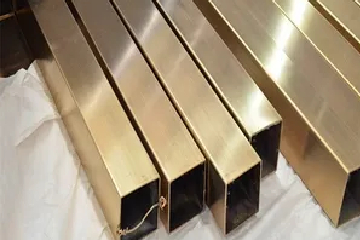

china centerless grinder machines

2. Advanced Technology Many Chinese manufacturers have adopted state-of-the-art technologies, such as CNC (Computer Numerical Control) and automated systems, to improve the precision and efficiency of their centerless grinders. These advancements contribute to enhanced productivity and reduced operational costs, making them increasingly popular among manufacturers worldwide.

3. Customization Chinese companies often offer a high degree of customization to meet the specific needs of clients. This flexibility allows manufacturers to modify machine features, such as the size of the grinding wheel or the overall machine configuration, resulting in tailored solutions that enhance operational efficiency.

4. Training and Technical Support Along with machine sales, many Chinese manufacturers provide comprehensive training and technical support, ensuring that clients can maximize the potential of their centerless grinders. This commitment to customer service fosters long-term relationships and repeat business.

The Future Outlook

The future of centerless grinding in China looks promising. As industries continue to adopt advanced machining processes to meet the demands of a competitive market, Chinese centerless grinder manufacturers are well-positioned to grow further. Continued investments in automation, AI technologies, and machine learning will likely lead to even more efficient and precise grinding machines.

Moreover, with the increasing emphasis on environmentally friendly manufacturing practices, Chinese manufacturers are also exploring sustainable options, such as energy-efficient motors and eco-friendly hydraulic systems, paving the way for greener production solutions.

Conclusion

As the manufacturing industry continues to evolve, the role of centerless grinder machines becomes increasingly crucial. China’s ability to produce high-quality, cost-effective, and technologically advanced centerless grinding machines highlights its significant position in the global market. As we look to the future, the continuous innovations and enhancements in this sector will undoubtedly shape the landscape of precision manufacturing both in China and around the world.