Understanding Centerless OD Grinder Quotation Exporters

In the realm of manufacturing and precision machining, centerless grinding has emerged as a critical process. This technique is exceptionally valued for its ability to produce high-accuracy cylindrical parts without the constraints associated with traditional grinding methods. As industries continue to expand, the demand for centerless OD (outer diameter) grinders has noted a significant uptick, leading to an increase in exporters specializing in this equipment. Understanding the dynamics surrounding centerless OD grinder quotation exporters is essential for businesses looking to enhance their machining capabilities.

What is Centerless Grinding?

Centerless grinding is a method used to grind cylindrical parts without the need for a chuck or collet to hold the workpiece. Instead, the part is supported on a work rest blade between a grinding wheel and a regulating wheel. This unique setup allows for continuous operation and the production of parts with tight tolerances and smooth finishes. Industries such as automotive, aerospace, and medical devices rely on centerless grinding due to its efficiency and precision.

The Role of Exporters in Centerless OD Grinding

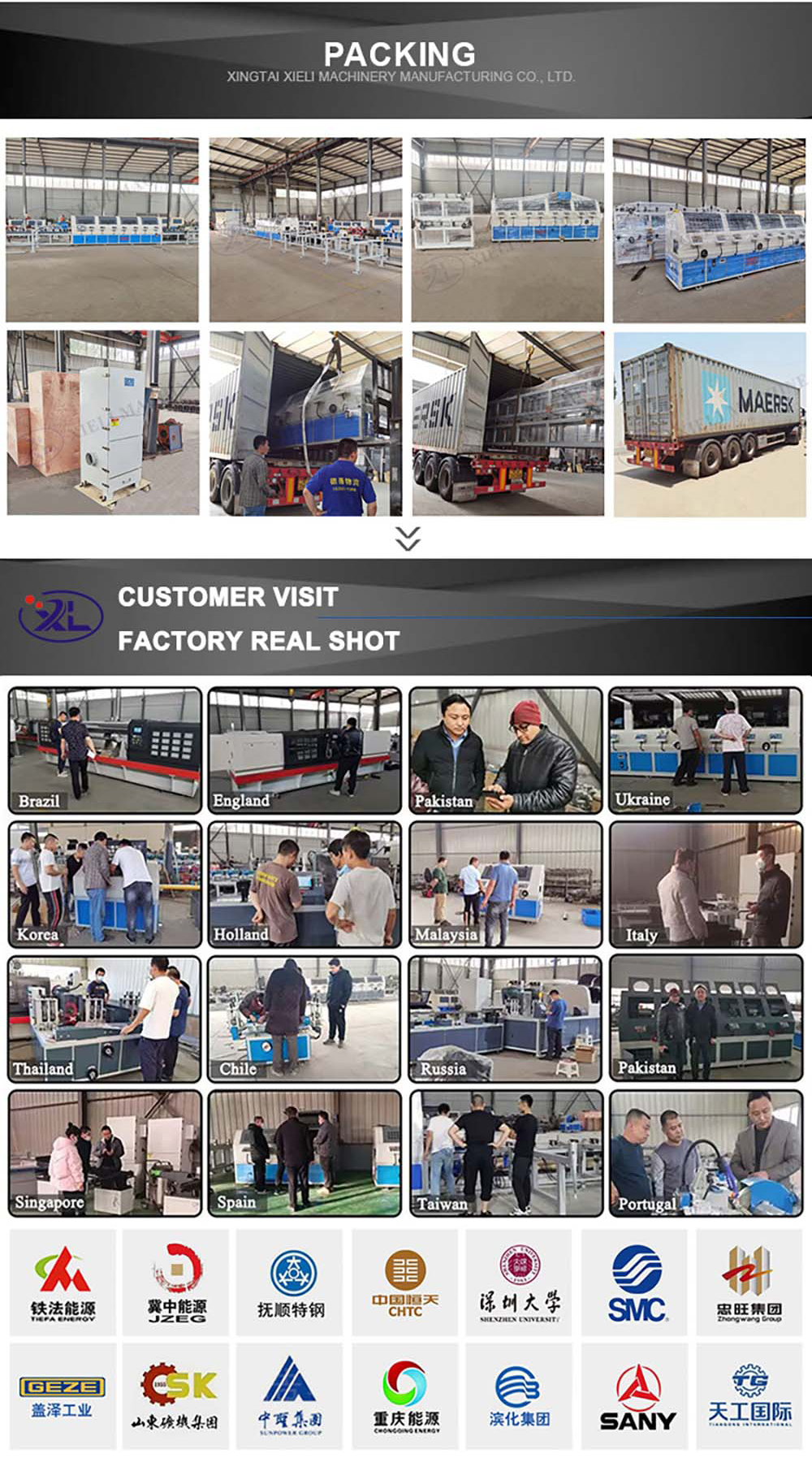

Exporters play a pivotal role in disseminating centerless OD grinders to various markets around the globe. These firms are responsible for sourcing high-quality machinery from manufacturers and distributing them to end-users. Their expertise extends beyond mere selling; they often provide essential services, including maintenance, training, and technical support, ensuring that buyers can maximize the productivity of their equipment.

Factors Influencing Quotations

When seeking a quotation for centerless OD grinders, several factors must be considered

1. Machine Specifications The specific requirements of the manufacturing process play a significant role in determining the type of grinder needed. Variations in size, capacity, and features will affect pricing.

centerless od grinder quotation exporters

2. Volume and Order Size Bulk orders may qualify for discounts, while smaller orders could lead to different pricing structures. Exporters often provide tiered pricing to accommodate varying order sizes.

3. Shipping and Handling International shipping can dramatically influence the final cost. Exporters must consider logistics, including transport methods, customs duties, and insurance when preparing quotes.

4. Market Demand Supply and demand dynamics can lead to fluctuations in pricing. As the demand for precision machinery rises, so too can the costs associated with it.

5. Service and Support Comprehensive after-sales support can add value to a quotation. Exporters who provide robust service agreements may justify higher prices due to the added peace of mind for the buyer.

Choosing the Right Exporter

Selecting an exporter for centerless OD grinders requires careful consideration. Businesses should look for exporters with a strong reputation, proven track records, and positive customer reviews. It's also beneficial to evaluate their technical expertise and level of customer support. Furthermore, transparency in quotations and a willingness to discuss terms are indicators of a reliable exporter.

Conclusion

The landscape of centerless OD grinder quotation exporters is continually evolving, driven by technological advancements and growing industrial requirements. For businesses in need of precision grinding solutions, understanding the nuances of this market is crucial. By taking into consideration the factors that influence quotations and choosing the right exporter, manufacturers can enhance their operational capabilities and remain competitive in an increasingly demanding market. As the global market continues to grow, the role of exporters will remain integral, ensuring that businesses have access to the tools they need to succeed.