The Importance of Stainless Steel Tube Polishing Machines

In today's industrial landscape, stainless steel has become a cornerstone material due to its unique combination of strength, corrosion resistance, and aesthetic appeal. One of the critical processes in enhancing the properties of stainless steel is the polishing of tubes. This is where stainless steel tube polishing machines come into play, significantly contributing to both the functionality and visual appeal of various products.

Understanding Stainless Steel Polishing

Polishing stainless steel tubes involves a series of processes aimed at achieving a smooth surface finish. This is vital for several reasons. Firstly, a polished surface reduces the likelihood of corrosion and contamination, making the tubes safer for transport and storage. Secondly, a polished finish is crucial for aesthetic purposes in sectors ranging from construction to food processing, where hygiene and appearance are paramount.

Polishing is not merely about creating a shiny surface; it plays a vital role in ensuring the durability and longevity of the stainless steel products. Well-polished tubes have lower friction coefficients, which can be particularly beneficial in various applications, including automotive, aerospace, and manufacturing.

The Role of Polishing Machines

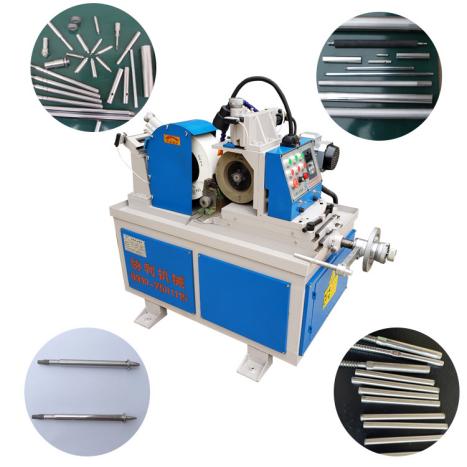

Stainless steel tube polishing machines automate the polishing process, resulting in more consistent finishes than manual methods. These machines employ various technologies, including abrasive belts, brushes, and even advanced robotic systems, to achieve the desired results. The automation of polishing not only enhances efficiency but also reduces labor costs and minimizes the risk of human error.

There are different types of polishing machines designed for specific needs. For example, some machines are designed for high-volume production lines, while others might cater to smaller businesses or custom jobs. The choice of machine often depends on factors such as the diameter of the tubes, the level of polish required, and the type of stainless steel being used.

Key Features of Modern Polishing Machines

Modern stainless steel tube polishing machines come equipped with numerous features that enhance their functionality and user-friendliness

. These features often includestainless steel tube polishing machine product

1. Adjustable Speed Settings Users can control the speed of the polishing process to achieve the desired finish, accommodating different stainless steel grades and tube specifications.

2. Multi-Axis Flexibility Advanced machines can polish tubes in various orientations, allowing for a more comprehensive finish, especially in hard-to-reach areas.

3. Integrated Dust Collection Systems These systems help maintain cleanliness and safety in the workspace by trapping the metal particles created during the polishing process.

4. User-Friendly Interfaces Many machines are equipped with digital controls and easy-to-read displays, allowing operators to monitor and adjust settings with ease.

5. Robust Construction High-quality materials and construction ensure that these machines can withstand industrial conditions while requiring minimal maintenance.

Applications Across Industries

The polished stainless steel tubes produced by these machines find applications in a variety of industries. In the food and beverage industry, for example, polished tubes are essential to maintain sanitary conditions and ensure compliance with health regulations. Similarly, in the pharmaceutical industry, polished stainless steel is critical for equipment and machinery that come into contact with drugs and biological products.

In the automotive sector, polished stainless steel tubes are often used in exhaust systems and frames, both for appearance and performance reasons. Additionally, architecture and design sectors have begun utilizing polished stainless steel for its aesthetic qualities in railings, furniture, and decorative elements.

Conclusion

As industries continue to evolve, the demand for high-quality, polished stainless steel tubes is only expected to grow. Stainless steel tube polishing machines are at the forefront of this development, providing the efficiency and precision necessary to meet these demands. Investing in state-of-the-art polishing technology can significantly enhance product quality, ensuring durability, safety, and visual appeal in an increasingly competitive market. By recognizing the crucial role of these machines, manufacturers can harness the full potential of stainless steel, paving the way for innovation and excellence across various sectors.