Metal Tube Polishing Machine Suppliers A Comprehensive Overview

In today's manufacturing landscape, the importance of aesthetics and functionality cannot be overstated. Particularly in industries where metal tubes are commonly used – such as automotive, aerospace, and furniture – the quality of surface finishing is critical. One of the most effective ways to achieve a high level of surface quality is through the use of metal tube polishing machines. Understanding the role, variety, and suppliers of these machines is essential for businesses aiming to enhance their products' appeal and performance.

What Are Metal Tube Polishing Machines?

Metal tube polishing machines are specialized equipment designed to finish the surfaces of metal tubes to a desired level of smoothness and shine. These machines utilize various polishing techniques, which can include mechanical buffing, abrasive polishing, and chemical processes. The goal is to remove imperfections, oxidation, and contaminants from the tube surfaces while achieving a reflective and attractive finish.

Types of Metal Tube Polishing Machines

There are several types of metal tube polishing machines available, each suited for different applications and requirements. Here are a few common varieties

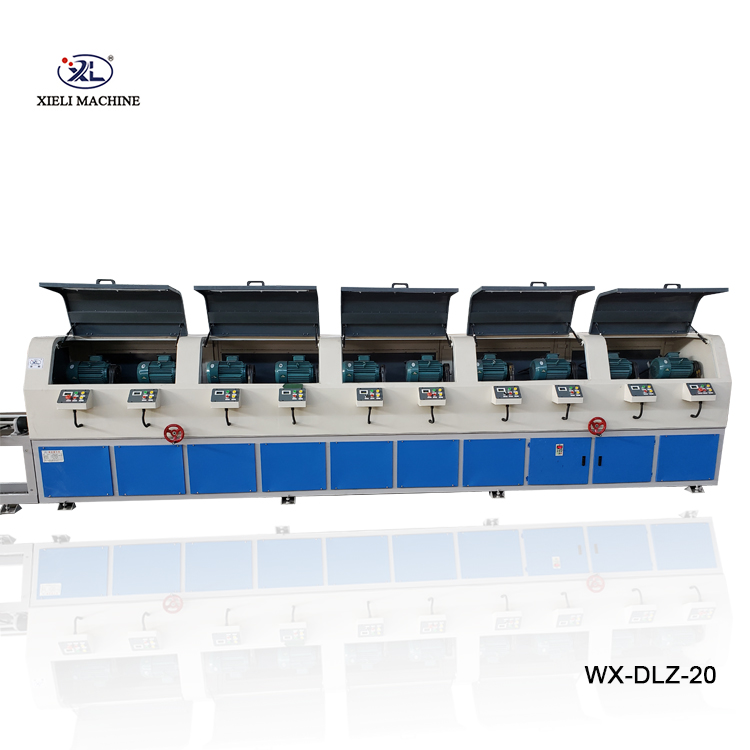

1. Automatic Polishing Machines These machines are designed for high-volume production. They operate with minimal manual intervention, ensuring consistency and efficiency. Automatic machines are ideal for manufacturers requiring large quantities of polished tubes in a short turnaround time.

2. Manual Polishing Machines While less common in mass production settings, manual machines offer more control and flexibility. They are often used for custom or specialized polishing needs and are preferred in smaller workshops.

3. CNC Polishing Machines These machines combine computer numerical control (CNC) technology with polishing capabilities. They can be programmed for intricate designs and are suitable for high-precision work, making them a favorite in industries where detail matters.

4. Buffing Machines Buffing machines are used specifically for achieving a high-gloss finish on metal tubes. They typically employ polishing compounds and wheels to produce a smooth surface, suitable for decorative purposes.

Key Suppliers of Metal Tube Polishing Machines

metal tube polishing machine suppliers

When searching for metal tube polishing machine suppliers, several names stand out in the industry due to their reputation for quality and reliability

1. KADIA Produktion GmbH Renowned for innovative polishing solutions, KADIA offers a range of machines specifically designed for different sizes and types of metal tubes. Their commitment to quality has made them a leading supplier in Europe and beyond.

2. Graco Inc. This company focuses on fluid handling technology, including advanced polishing systems for metal surfaces. Their equipment is known for durability and efficiency, making them a trusted name in various industries.

3. Rösler Oberflächentechnik GmbH A major player in the surface finishing sector, Rösler offers a wide array of polishing machines suitable for metal tubes. Their products are designed for efficiency and effectiveness, ensuring high-quality finishes.

4. Abrasive Finishing Systems This supplier specializes in abrasive polishing technology and offers tailored solutions for various metal polishing needs. Their expertise allows them to provide specific advice on machine selection based on individual client requirements.

5. Suhner Group With a diverse portfolio, Suhner specializes in professional polishing and abrasive solutions. Their metal tube polishing machines are built to provide high performance while accommodating different production scales.

Choosing the Right Supplier

Selecting the right supplier for metal tube polishing machines requires careful consideration of several factors

- Experience and Reputation Look for suppliers with a proven track record in the industry and positive customer reviews. - Product Range A supplier that offers a variety of machines can cater to diverse requirements, from small workshops to large-scale manufacturers. - Technological Compatibility It's essential to choose a supplier whose machines integrate well with your existing production processes. - Support and Service Consider suppliers that provide excellent customer support, including training and maintenance, to ensure the longevity of your investment.

Conclusion

In conclusion, the choice of a metal tube polishing machine supplier can significantly impact the quality of the final product. By understanding the types of machines available and the key players in the market, businesses can make informed decisions that enhance their production processes and product offerings. As industries continue to evolve, the demand for high-quality metal finishing will remain crucial, ensuring that metal tube polishing machines will play an integral role in manufacturing for years to come.