The Significance of CE Certification for Square and Rectangle Tube Polishing Machines

In the modern manufacturing sector, machinery such as tube polishing machines plays a vital role in producing high-quality metal products. Among the various styles of tube polishing machines, those designed for square and rectangle tubes are particularly essential in industries that require precise finishes for structural and decorative purposes. However, the efficiency and safety of these machines significantly depend on compliance with industry standards, most notably CE certification.

Understanding CE Certification

CE certification signifies that a product meets the essential health, safety, and environmental protection requirements set forth by the European Union (EU). This mark not only reflects the manufacturer’s commitment to quality but also ensures that the product complies with EU legislation, which is crucial for market access within Europe. For manufacturers of tube polishing machines, obtaining CE certification is not just a regulatory requirement; it also enhances marketability and adds to the credibility of their products.

Importance of Tube Polishing Machines

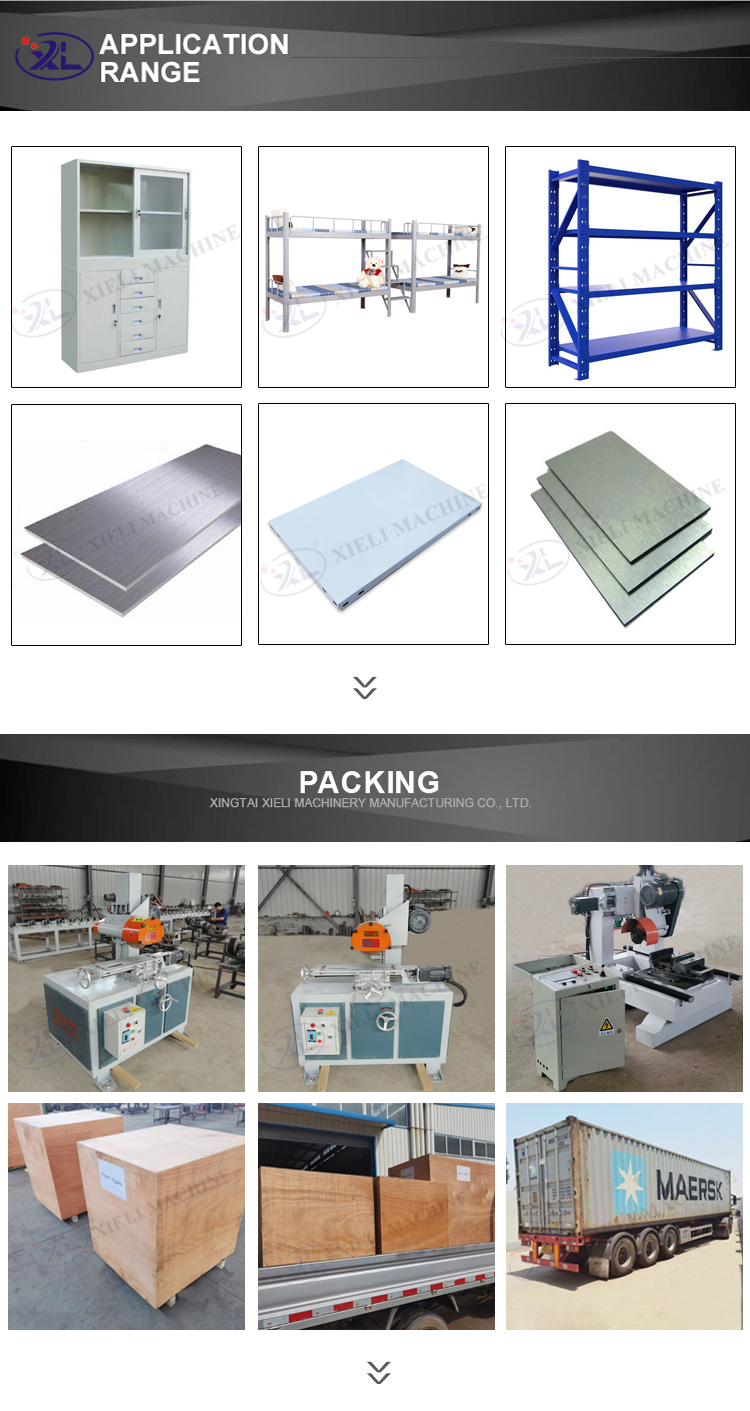

Square and rectangle tube polishing machines are used in a variety of applications, ranging from automotive components to architectural structures. These machines are designed to achieve a high-quality surface finish, which is essential for both aesthetic and functional purposes. A polished surface can enhance corrosion resistance, reduce friction, and improve the overall appearance of the finished product. Given the increasing demand for quality and safety in manufacturing, the role of these machines cannot be understated.

The Polishing Process

The tube polishing process involves several steps to ensure a smooth, mirror-like finish. Initially, the tubes are cleaned to remove any contaminants. They are then subjected to abrasive polishing, which can include a range of mechanical methods such as buffing or grinding. Finally, a finer finish is applied using various polishing compounds. The entire process must be conducted with precision to ensure that the dimensions of the tubes remain unchanged while achieving the desired finish.

ce certification square rectangle tube polishing machine

Benefits of CE Certification

1. Market Access CE certification opens doors to the European market. Manufacturers without this certification may find it challenging to sell their machines in EU countries, which can limit their business opportunities.

2. Enhanced Safety CE certification ensures that the polishing machines meet stringent safety requirements. This reduces the risk of accidents and injuries in the workplace, making it safer for operators.

3. Quality Assurance Machines that are CE certified typically undergo rigorous testing and quality checks. This guarantees that they will perform reliably and effectively, thereby meeting customer expectations.

4. Increased Competitiveness In a highly competitive market, having the CE mark can distinguish a manufacturer’s products from those of competitors. This certification can serve as a strong selling point when pitching to potential customers.

5. Regulatory Compliance Compliance with EU regulations is crucial for avoiding legal penalties and ensuring long-term sustainability. CE certification simplifies the process of meeting these regulations.

Conclusion

As industries increasingly focus on quality, safety, and environmental responsibility, the importance of CE certification for manufacturing equipment like square and rectangle tube polishing machines cannot be overlooked. This certification represents a commitment to upholding the highest standards, ensuring that products are not only efficient but also safe for use. For manufacturers, investing in CE certification is a strategic step that can lead to increased market access, enhanced safety, and improved competitiveness. As the demand for precision-polished tubes continues to grow, those manufacturers that prioritize and achieve CE certification will likely lead the way in innovation and quality in the tube manufacturing industry.