Choosing the Right Pipe Polishing Machine Supplier

In today’s manufacturing landscape, the demand for high-quality polished pipes has soared. Industries ranging from construction to automotive need pipes that not only fulfill functional requirements but also boast aesthetic appeal. As a result, the role of pipe polishing machine suppliers has become pivotal in ensuring that businesses acquire machinery that meets their specific needs. This article will guide you through the key considerations when choosing a supplier for pipe polishing machines.

Understanding Your Needs

Before you start looking for a supplier, it is critical to understand your specific requirements. Different types of pipes—whether they're stainless steel, aluminum, or carbon steel—require various polishing techniques and machines. Assess the types of pipes you need to polish, the volume of production, and the desired finish quality. A clear understanding of these factors will enable you to communicate effectively with potential suppliers and evaluate their offerings accurately.

Researching Suppliers

Once you have a clear understanding of your needs, begin researching potential suppliers. Look for companies that specialize in pipe polishing machines and have a good reputation in the industry. Online directories, industry trade shows, and forums are excellent resources for finding credible suppliers. Pay attention to customer reviews and testimonials, as they can provide insights into the reliability and efficiency of the machines offered.

Evaluating Quality and Technology

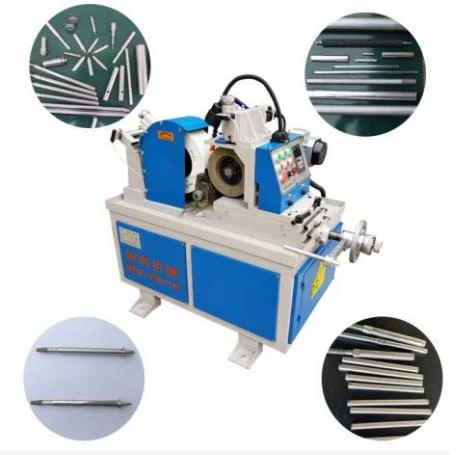

Quality should be the foremost criterion when selecting a pipe polishing machine supplier

. The best suppliers utilize the latest technologies to ensure that their machines provide consistent performance and superior finish quality. Look for features like automated controls, adjustable polishing speeds, and multiple finishing options.Additionally, ensure that the suppliers adhere to stringent quality control processes and industry standards. Well-established suppliers often have their machines tested by independent third-party entities, providing you with more assurance about their quality.

After-Sales Support and Service

pipe polishing machine supplier

Another critical factor is the level of after-sales support and service offered by the supplier. Pipe polishing machines are significant investments, and having reliable support can be a game-changer when it comes to maintenance and troubleshooting. Opt for suppliers that offer comprehensive after-sales services, including installation, training, and ongoing technical support. Check whether they provide service contracts, availability of spare parts, and response times for on-site support.

Customization and Flexibility

Every business has unique requirements, and the ability to customize a machine can set a supplier apart. Ask potential suppliers whether they offer customized solutions to meet specific needs. This might include changes in machine size, additional polishing heads, or tailored software for more precise control over polishing operations. A supplier willing to work with you on customization demonstrates flexibility and a commitment to meeting customer expectations.

Cost Considerations

While price should not be the only factor in your decision-making process, it is undoubtedly an important one. Compare the pricing of different suppliers, and ensure that the quotations encompass all potential costs, including shipping, installation, and ongoing operational expenses. Be wary of overly cheap machines, as they might compromise on quality or durability. Instead, focus on finding a supplier who offers the best value for the quality of machinery provided.

Building a Relationship

Finally, consider the long-term relationship you can build with your supplier. A good relationship can lead to better support, favorable pricing, and collaborative opportunities for improvement. Look for suppliers who are open to communication, value your business, and are interested in your long-term success.

Conclusion

Choosing the right pipe polishing machine supplier is a critical decision that can significantly impact your production efficiency and product quality. By understanding your needs, researching potential suppliers, evaluating their technology and support services, and considering customization options, you can make a well-informed choice. Investing time in this decision can ultimately lead to smoother operations and a stronger competitive edge in the marketplace.