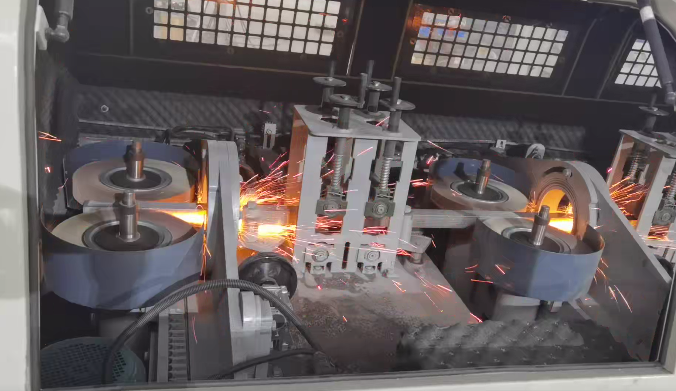

Centerless Grinder Training Supplier Enhancing Precision and Efficiency

In the world of manufacturing, precision is paramount, and centerless grinding is one of the key processes that enables the production of high-quality components. Centerless grinders are essential machines in industries such as automotive, aerospace, and medical device manufacturing, where tight tolerances and surface finish are critical. To ensure that operators are equipped with the necessary skills and knowledge to maximize the capabilities of these machines, the role of a centerless grinder training supplier becomes increasingly important.

A dedicated centerless grinder training supplier offers comprehensive training programs geared towards helping operators understand the intricacies of centerless grinding. These programs typically cover essential topics such as machine setup, operation, troubleshooting, and maintenance. By addressing both theoretical knowledge and practical skills, training suppliers ensure that participants grasp the fundamental principles of centerless grinding and how to apply them effectively on the shop floor.

One significant advantage of partnering with a reputable training supplier is access to experienced instructors. These professionals often have extensive backgrounds in manufacturing and engineering, allowing them to provide insights that go beyond standard training. With real-world examples and hands-on experience, trainees can develop a robust understanding of best practices and innovative techniques that can enhance productivity and product quality.

centerless grinder training supplier

Moreover, a good training program will incorporate the latest advancements in centerless grinding technology. As the industry evolves, it is crucial for operators to be familiar with modern machinery and software that can increase efficiency and reduce downtime. Training suppliers often collaborate with machinery manufacturers to ensure that their curriculums are up-to-date with current trends and advancements in the field.

The benefits of training extend beyond individual operators. For organizations, investing in proper training for centerless grinders can lead to significant improvements in overall performance. Well-trained employees are less likely to make errors that could lead to waste or rework, thus contributing to cost savings and enhanced production capabilities. Furthermore, a knowledgeable workforce can foster an environment of continuous improvement, where employees are encouraged to identify problems and seek innovative solutions.

In conclusion, engaging with a centerless grinder training supplier is a strategic investment for companies aiming to enhance their machining processes. By providing comprehensive training that focuses on both theory and practice, these suppliers equip operators with the skills needed to optimize the performance of centerless grinders. This not only boosts individual proficiency but also elevates the entire organization's efficiency and competitiveness in the market. As manufacturing continues to advance, continuous training in critical areas like centerless grinding will remain a vital component of success.