The world of manufacturing has undergone a transformation with the advent of advanced machining tools, and among these, the centerless grinder stands out as a pinnacle of precision and efficiency. With myriad industries relying on the accuracy and speed of centerless grinding, it’s essential to delve into the true capabilities and robust advantages offered by this machinery.

Centerless grinders, a subclass of external grinding machines, are engineered to remove material efficiently from a workpiece. Unlike traditional cylindrical grinders, centerless grinders do not require the workpiece to be mechanically constrained. What this means for manufacturers is a significant enhancement in production speed and a notable decrease in labor costs. Instead of being held between centers, the workpiece is situated between a grinding wheel and a regulating wheel. This design eliminates the need for axial positioning and workpiece centering, making the process inherently faster and more adaptable to high-volume production lines.

Experience dictates that the seamless operation of a centerless grinder pivots on the precise alignment and condition of both wheels. An expert operator appreciates that the feed rate, blade angle, and wheel speed are paramount for achieving unparalleled accuracy. It is this mastery of the intricate balance between speed and precision that distinguishes professional operators from their peers. With routine maintenance and exacting attention to the wheel dressing, a centerless grinder can execute complex projects with remarkable consistency and minimal variation.

Esteemed for its utility in various sectors, the centerless grinder is indispensable in industries ranging from automotive to aerospace, and even in consumer electronics.

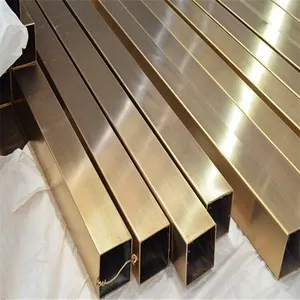

The reliability of centerless grinding in producing rods, tubes, bearings, and shafts cannot be overstated. Its prowess is further exemplified in its ability to work with a vast array of materials—whether soft alloys or hard metals. This versatility ensures that the centerless grinder remains a staple in modern manufacturing processes.

centerless grinder

In terms of cutting-edge advancements, manufacturers have continued to refine the technology, incorporating sophisticated control systems and enhanced automation. These improvements not only elevate the precision capabilities of the machines but also significantly boost throughput. The integration of real-time monitoring and adjustments ensures the longevity of the equipment and maintains the highest standards of product quality.

When considering the authority and over-arching trustworthiness of a centerless grinder, it's pertinent to consider both the historical reliability of these machines and their proven track record in enhancing manufacturing output. Industry leaders who invest in centerless grinding technology are often rewarded with reduced downtime, increased production rates, and a distinctive edge over competitors reliant on more traditional grinding methods.

In sum, centerless grinders embody the perfect amalgamation of precision engineering and practical efficiency. Their continued evolution reflects the manufacturing industry's push towards optimizing production processes while maintaining uncompromised quality standards. For enterprises aiming to excel in high-demand markets, investing in a centerless grinder is not just a choice—it's a pathway to elevated excellence and sustained success.

For More Details Pls Contact Us

Fiberglass Reinforced Plastic (FRP), also known as fiber-reinforced plastic, is a composite material widely used across various industries.