-

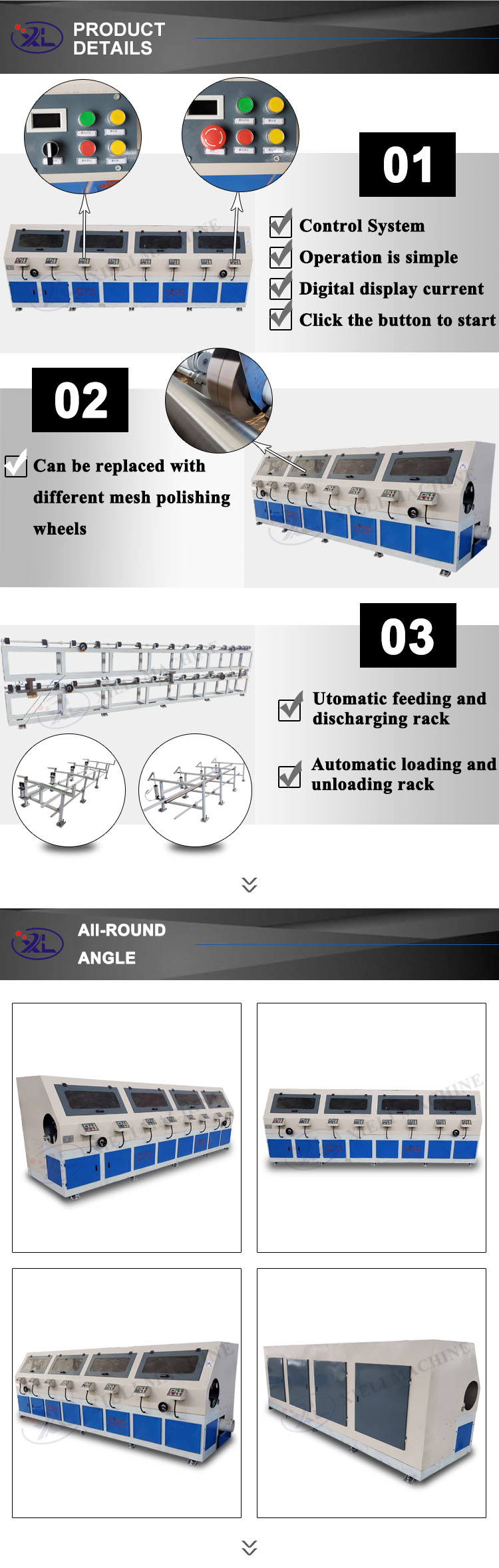

Products Detail

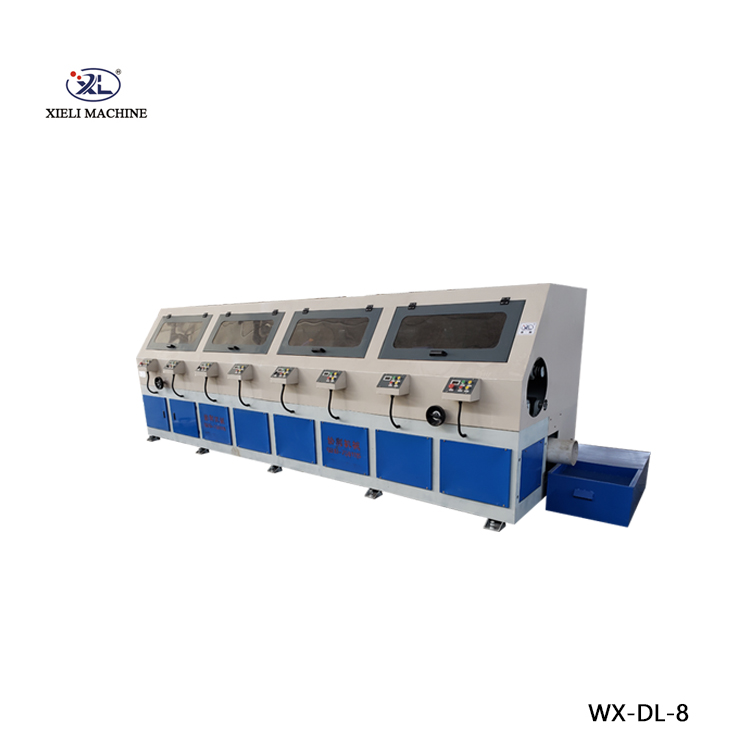

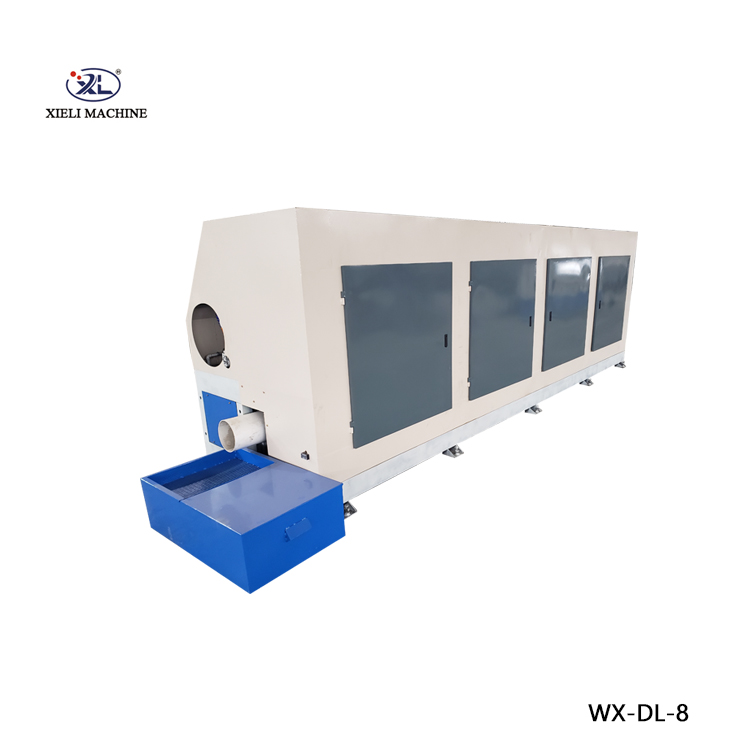

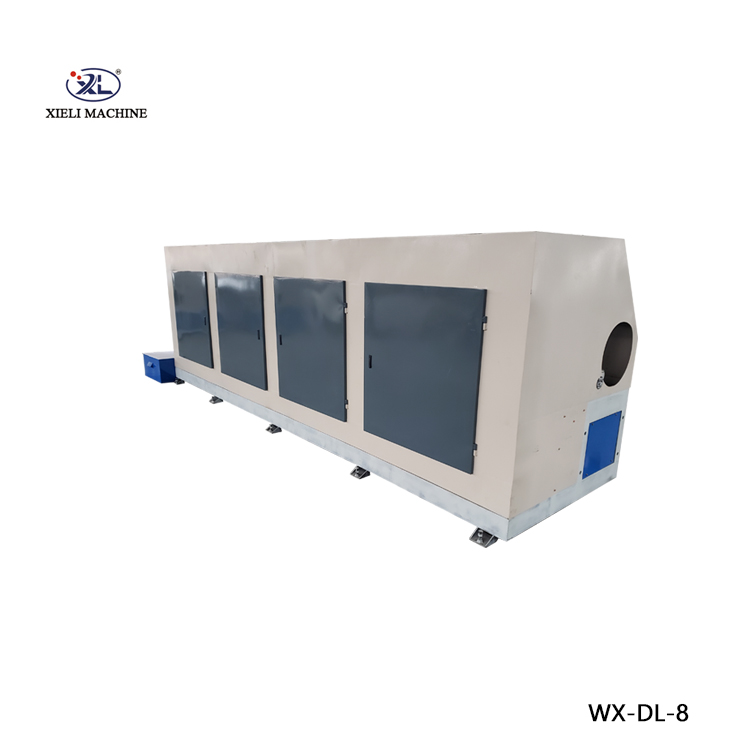

WX-DL series large diameter hydraulic tube polishing machine

Main purpose and scope of application:

Round pipe polishing machine is mainly used for the derusting and polishing of hardware manufacturing, vehicle accessories, hydraulic cylinder, steel and wood furniture, instrument machinery, standard parts and industries before and after electroplating, from rough polishing to fine polishing. A variety of brown and white corundum grinding wheels and polishing wheels such as, Chiba wheel, hemp wheel, nylon wheel, wool wheel, cloth wheel, PVA, etc. can be installed in the round tube polishing machine. The guide wheel has stepless speed control, which is simple and convenient to operate. The steel structure is optimized to make the performance more stable. The reserved fan port can be equipped with a dust removal fan or a wet dust removal system, which can be matched with an automatic feeding and unloading mechanism according to the length of the processed parts. This device It can be equipped with grinding wheel to grind pin and remove oxide skin (peeling off) on the surface of round steel and pipe with serious defects.

Main specification parameters:

(Special polishing equipment can be customized according to user requirements)

Project

Model

WX-DL-2

WX-DL-4

WX-DL-6

WX-DL-8

WX-DL-10

Input voltage(v)

380V(Three phase four wire)

Input power(kw)

13.2

22.2

30.7

38.7

46.7

Polishing wheel

specification(mm)

250/300*40/50*32(Width can be assembled)

Guide wheel

specification(mm)

110

Polishing wheel

speed(r/min)

3000

Guide wheel speed(r/min)

Stepless speed regulation

Machining diameter(mm)

20-360

Processing efficiency(m/min)

0-8

Surface roughness (um)

Ra 0.02

Processing length(mm)

Determined by bracket length (0.3-12)

Dry fan dust removal

optional

Wet water cycle dust removal

optional

Grinding head

feeding mode

Digital display electromagnetic hydraulic control

Passive guide wheel adjustment method

Manual/electric/automatic optional

Machine tool total weight about(kg)

2000

3000

4000

5000

6000

Equipment dimension(m)

1.3*1.2*1.5

2.6*1.2*1.5

3.9*1.2*1.5

5.2*1.2*1.5

6.5*1.2*1.5

Ko te miihini whakakoi ngongo a tawhio noa kia rite ki nga tauira tauira ki te wehewehe, mai i te tapeke o nga wira whakakoi ka taea te wehea ki te ngawarix me te maha-teihana a tawhio noa ngongo miihini whakakoi, ko te miihini miihini ngawari he kotahi noa te roopu o te miihini whakakoi wira, he maha nga teihana miihini miihini kei roto i nga roopu 2 o nga roopu oro.

The main function of the single station and multi-station round pipe polishing machine is the same, and it can be used to prevent and polish the surface layer of the workpiece such as seamless steel pipe, galvanized pipe, iron bar, aluminum alloy pipe, etc., but the single station round pipe polishing machine has only one set of polishing wheels, and it will develop a polishing treatment for the workpiece once through the tube, which is generally used for workpiece rust removal and rough polishing.

Or the development of polishing processing for small workpieces of long and thin shaft parts, the equipment is characterized by lightweight organization and faster polishing speed.

The name of the outer circle polishing machine

Circular polishing machine is also known as centerless polishing machine, centerless circular polishing machine, circular tube polishing machine, slender shaft polishing machine.

Second, the classification of circular polishing machine

According to the shape of the workpiece can be divided into plane polishing machine, ball polishing machine, square tube polishing machine, strip polishing machine. According to its polishing process, it can be divided into a single group of cylindrical polishing machine and multiple groups of vertical cylindrical polishing machine and multiple groups of horizontal polishing machine. Third, the use of circular polishing machine

Cylindrical polishing machine is mainly used for hardware production, vehicle parts, steel and wood furniture, appearance machinery, standard parts and other industries before and after electroplating rust and polishing, is a good choice for round pipe, round rod, slender shaft polishing. The workpiece processed by the circular tube polishing machine has high brightness and does not affect the original size of the workpiece, which is especially suitable for the high-gloss polishing of the workpiece processed by the centerless grinder.

Fourth, the characteristics of the circular polishing machine

The round tube polishing machine has high working efficiency, good surface roughness of the workpiece and stable function. The machine guide wheel speed frequency conversion control (optional), so no matter the size of the workpiece diameter, length, can get the ideal processing efficiency.

Centerless cylindrical polishing machine (grinder) with high efficiency, high finish, easy to operate, can choose all kinds of grinding tools and other characteristics. This machine is mainly used in: hardware, electroplating, steel and wood furniture, standard parts, auto and motorcycle parts and other production industries. It is suitable for grinding and polishing the outer surface of various shafts, rods and pipe fittings. Ultra-long stainless steel tube, boiler tube, high-precision tube, titanium alloy rod; Construction machinery hydraulic rod, automobile and motorcycle shock absorber rod, valve rod, oil field pumping rod; Polishing and grinding of all kinds of metal/non-metal rods, tubes, plastics, rubber tubes, spinning machine rods and wire rods.

-

Need Our Services And Quotes?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

- Awherika

- Albanian

- Amharic

- Arapi

- Arameni

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosniana

- Bulgarian

- Katarana

- Cebuano

- Haina

- Haina (Taiwan)

- Korihika

- Koroatiana

- Czech

- Teniana

- Tatimana

- Ingarihi

- Esperanto

- Estonian

- Finnish

- Wīwī

- Frisian

- Kariri

- Georgian

- Tiamana

- Kariki

- Gujarati

- Haiti Creole

- Hausa

- hawaii

- Hiperu

- Kao

- Miao

- Hungarian

- Tiorangi

- igbo

- Initonia

- Irish

- Itari

- Hapanihi

- Hawaana

- Kannada

- Kazakh

- Khmer

- Rwandan

- Koreana

- Kurdish

- Kyrgyz

- Reipa

- Latina

- Latvian

- Lithuanian

- Luxembourgish

- Makeronia

- Maori

- Malay

- Malayalam

- Marite

- Maori

- Mareti

- Mongolian

- Myanmar

- Nepali

- Norewai

- Norewai

- Occitan

- Pashto

- Pahia

- Porohia

- Potiti

- Punjabi

- Romanian

- Ruhia

- Hamoa

- Scottish Gaelic

- Serbian

- Ingarihi

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Paniora

- Hatana

- Swahili

- Huitene

- Tagalog

- Tajik

- Tamil

- Tatara

- Telugu

- Thai

- Turiki

- Turkmen

- Iukereiniana

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Awhina

- Yiddish

- Zulu