The Role of Tube Buffing Machine Exporters in Global Trade

In today’s manufacturing landscape, the quest for quality and efficiency has never been more critical. As industries around the world strive to produce superior products while maintaining cost-effectiveness, the demand for advanced machinery has surged. Among these machines, tube buffing machines stand out as essential tools for achieving high-quality finishes on metal tubes. Exporters specializing in tube buffing machines play a vital role in facilitating this demand, impacting industries across the globe.

Understanding Tube Buffing Machines

Tube buffing machines are specialized equipment designed to polish and buff metal tubes to enhance their surface finish. These machines utilize various techniques, such as mechanical buffing with the use of abrasive pads or polishing compounds, to remove imperfections, improve aesthetics, and provide corrosion resistance. The application of tube buffing machines extends across various sectors, including automotive, aerospace, construction, and home appliances. As such, their importance in modern manufacturing cannot be overstated.

The Global Demand for Tube Buffing Machines

The growing global demand for high-quality metal products has led to an increase in the need for tube buffing machinery. Emerging markets, particularly in Asia and Africa, are expanding their manufacturing capabilities, necessitating advanced equipment for competitive production. Furthermore, the push towards sustainability and innovation in manufacturing processes has propelled the need for machines that not only enhance product quality but also optimize resource usage.

Exporters of tube buffing machines are well-positioned to meet this demand, providing advanced solutions tailored to various industry requirements. They enable manufacturers worldwide to access cutting-edge technology that they might not have the capacity or resources to develop internally.

The Export Dynamics of Tube Buffing Machines

The exporters of tube buffing machines often operate in a dynamic and complex global trade environment. They must stay abreast of international trade regulations, tariffs, and market trends that can impact their operations. Building strong relationships with manufacturers, suppliers, and logistics providers is essential for navigating this landscape successfully.

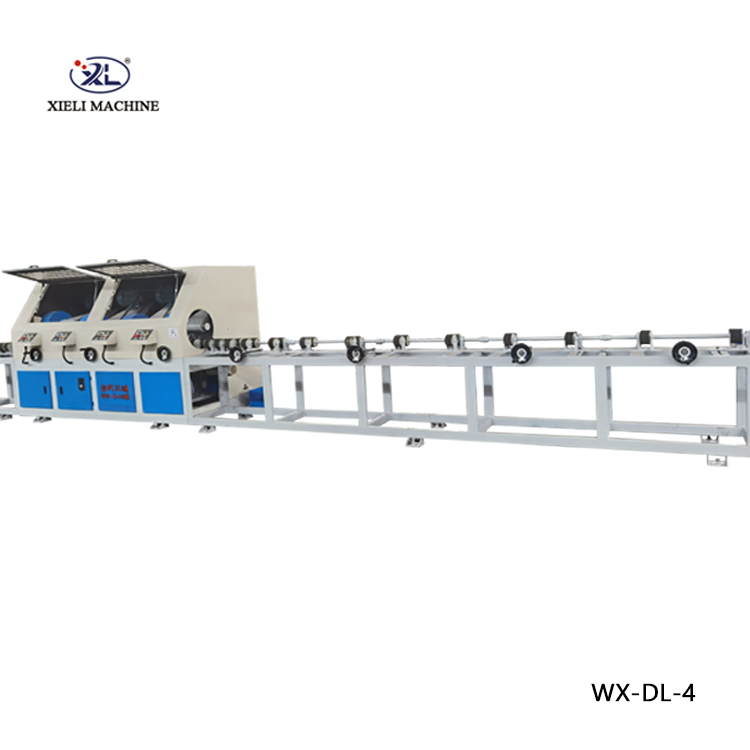

tube buffing machine exporters

Exporters typically specialize in different types of buffing machines. Some focus on high-end, automated systems equipped with state-of-the-art technology, while others may provide more cost-effective solutions for smaller operations. This diversity allows them to cater to a broad spectrum of clients, from small workshops to large industrial operations.

Challenges Faced by Exporters

While the opportunities in the tube buffing machine export market are plentiful, exporters also face challenges. One significant hurdle is the rapid pace of technological advancement. Staying competitive requires constant investment in research and development, which can strain resources, particularly for smaller exporters.

Additionally, exporters must contend with varying quality standards and customer expectations in different regions. Understanding these nuances is crucial for establishing trust and credibility in foreign markets. Providing comprehensive after-sales support and demonstrating a commitment to quality can significantly enhance an exporter’s reputation and customer retention.

The Future of Tube Buffing Machine Exporters

Looking ahead, the role of tube buffing machine exporters will likely evolve as new technologies emerge. Integration with automation, such as robotics and artificial intelligence, is becoming increasingly prevalent. Exporters who can offer such advanced solutions will likely find themselves at the forefront of the industry.

Moreover, global trends towards sustainability and eco-friendly practices will influence the development and export of tube buffing machines. Machines that minimize waste and energy consumption will not only appeal to environmentally-conscious buyers but will also align with industry's future direction.

In conclusion, tube buffing machine exporters play a pivotal role in the global manufacturing landscape, enabling businesses to achieve high standards of quality and efficiency. As industries continue to evolve, these exporters will undoubtedly be instrumental in driving innovation and meeting the diverse needs of manufacturers worldwide. Their capacity to adapt and grow will determine their position in an increasingly competitive market, underscoring the importance of their work in the global economy.