Exploring the Benefits of Multi-Head Automatic Polishing Machines

In the realm of industrial manufacturing, efficiency and precision are paramount. As businesses strive to enhance product quality while minimizing operational costs, the demand for advanced machinery has never been higher. Among these innovations, multi-head automatic polishing machines have emerged as game changers for companies across various sectors.

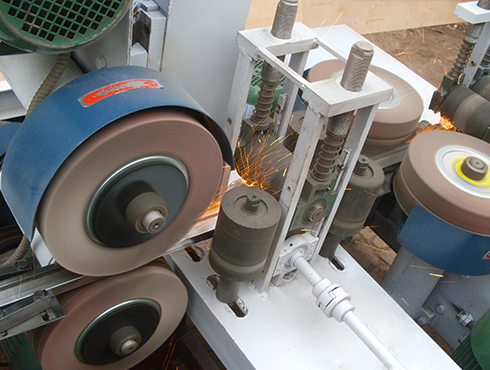

Multi-head automatic polishing machines are designed to streamline the polishing process by integrating multiple polishing heads, allowing for simultaneous operation. This technology significantly reduces processing time compared to traditional single-head machines. For manufacturers dealing with large volumes of products, the efficiency gained from using multi-head systems can lead to substantial improvements in output and productivity.

One of the standout features of these machines is their ability to provide uniformity in the polishing process. Achieving a consistent finish is crucial, especially in industries such as automotive, aerospace, and electronics, where product aesthetics and surface integrity are vital. Multi-head machines ensure that each item receives the same level of polish, minimizing the risk of defects and enhancing product quality.

multi-head automatic polishing machine companies

Moreover, the automation of the polishing process mitigates human error and reduces labor costs. With minimal operator intervention required, companies can allocate human resources to other critical areas of production, optimizing workflows and boosting overall efficiency. Advanced automation also interfaces with software for real-time monitoring, allowing manufacturers to track performance metrics and make informed decisions swiftly.

In addition to efficiency gains, investing in a multi-head automatic polishing machine can significantly enhance the versatility of a manufacturing operation. These machines can be configured to accommodate a variety of materials, including metals, plastics, and composites. This adaptability allows companies to expand their product lines and cater to diverse customer needs without significant alterations to their existing setups.

The initial investment in multi-head automatic polishing machines may seem substantial; however, the long-term benefits often outweigh the costs. Reduced processing time, increased product quality, and lower labor expenses contribute to a favorable return on investment.

In conclusion, multi-head automatic polishing machine companies are at the forefront of revolutionizing manufacturing operations. By integrating advanced technology into the polishing process, these machines offer unparalleled efficiency, consistency, and adaptability. For manufacturers looking to stay competitive in an ever-evolving market, embracing this technology could be the key to unlocking new levels of success and innovation.