Understanding Metal Surface Polishing Machine Quotes A Comprehensive Guide

In the industrial sector, the demand for high-quality metal surface finishing techniques is paramount. Among the various finishing processes, metal surface polishing stands out as a critical operation to achieve the desired aesthetic and functional properties of metal components. Whether you are in the automotive, aerospace, or manufacturing industries, investing in the right metal surface polishing machine is essential. This article aims to shed light on the intricacies of obtaining quotes for metal surface polishing machines, helping you make an informed purchasing decision.

The Importance of Metal Surface Polishing

Metal surface polishing not only enhances the appearance of metal parts but also improves their durability and resistance to corrosion. A well-polished surface reduces friction, which can prolong the lifespan of components in various applications. For industries that require stringent quality standards, such as aerospace and medical devices, investing in advanced polishing technology is indispensable.

Types of Metal Surface Polishing Machines

Before obtaining quotes, it is crucial to understand the different types of metal surface polishing machines available

1. Manual Polishing Machines These are typically less expensive and allow for hands-on control. However, they may require skilled operators to achieve optimal results. 2. Automatic Polishing Machines Designed for high-volume production, these machines often provide consistent and uniform results but come at a higher price point. Features such as programmable settings and advanced robotics are common in these models. 3. CNC Polishing Machines Computer Numerical Control (CNC) machines allow for precise polishing based on digital designs. They are ideal for complex shapes and tight tolerances, albeit with a significant initial investment. 4. Ultrasonic Polishing Machines Utilizing high-frequency sound waves, these machines offer precision polishing for intricate parts, often used in the jewelry and electronics industries.

Factors Influencing Quotes

When acquiring quotes for metal surface polishing machines, several factors come into play that influence the overall price

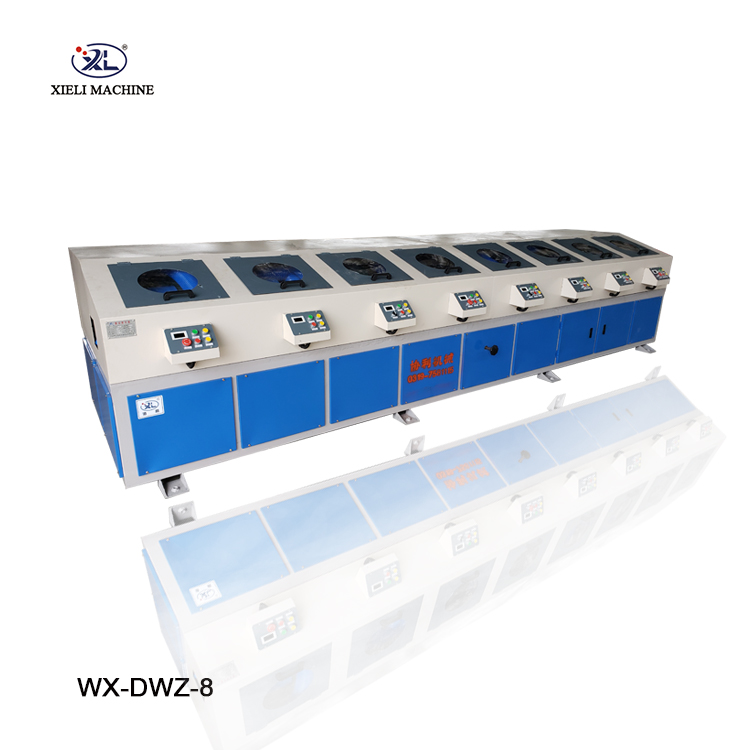

metal surface polishing machine quotes

1. Machine Type As described above, the type of machine significantly affects the price. Manual machines will generally be more affordable than automated or CNC options.

2. Specifications and Features The capabilities of the machine, such as speed, size, and the materials it can handle, will impact the quote. Machines with advanced features like programmable controls or interchangeable parts often come with a higher price.

3. Brand and Manufacturer Established brands with a reputation for quality and customer support may charge a premium. However, investing in renowned brands can often lead to lower long-term maintenance costs.

4. Volume and Customization If you need a machine tailored to specific production volumes or unique processing requirements, custom solutions will incur additional costs.

5. Market Trends and Economic Factors The market dynamics, including demand for metal polishing equipment and raw material costs, can cause fluctuations in pricing. Staying informed about these trends can help you negotiate better prices.

Requesting and Comparing Quotes

To obtain accurate quotes, it is advisable to approach multiple suppliers. Provide them with detailed specifications regarding your polishing needs. This may include material types, production volume, required finish quality, and any other specific requests. Once you receive the quotes, compare them not just on price, but also on the value provided - such as warranty, after-sales service, and ease of use.

Conclusion

Investing in a metal surface polishing machine is a significant decision that can greatly influence the quality of your products and manufacturing efficiency. Understanding the types of machines available and the factors that affect pricing can help you navigate the quoting process more effectively. By sourcing quotes from various suppliers and thoroughly evaluating your options, you can ensure that you make a well-informed purchase that meets your operational needs and budget constraints. Whether you choose a manual, automatic, or CNC machine, the right choice will undoubtedly enhance your metal finishing processes and propel your business towards success.