The Advantages of OEM Centerless Grinders A Focus on Tiger Stripe Technology

In the world of precision manufacturing, the need for high-quality grinding solutions is paramount. Centerless grinders have emerged as a crucial tool in the shaping and finishing of products, allowing for high-speed, efficient processing of various materials. Among the innovations in this field is the application of Tiger Stripe technology in OEM (Original Equipment Manufacturer) centerless grinders. This article explores the benefits of OEM centerless grinders infused with Tiger Stripe technology, their working principles, and their impact on modern manufacturing.

Understanding Centerless Grinding

Centerless grinding is a machining process that involves removing material from the outer diameter of a workpiece. Unlike traditional grinding, where the part is held in place, centerless grinding employs a system that supports the workpiece between two wheels—a grinding wheel and a regulating wheel. This configuration allows for the continuous feed of parts without the need for additional fixtures or setups, making it ideal for high-volume production.

The Role of OEM in Grinding Technology

Original Equipment Manufacturers (OEMs) are critical players in providing advanced machinery tailored to the needs of specific industries. In the realm of centerless grinders, OEMs focus on integrating cutting-edge technologies to enhance performance, reliability, and overall efficiency. By leveraging innovations such as automation, advanced materials, and precision engineering, OEMs can create bespoke solutions that meet the diverse needs of various applications.

Introducing Tiger Stripe Technology

Tiger Stripe technology is a noteworthy advancement in the field of centerless grinding. Characterized by its unique surface design resembling the stripes of a tiger, this technology involves a special grinding wheel formulation that enhances the grinding process. The benefits of Tiger Stripe technology can be summed up as follows

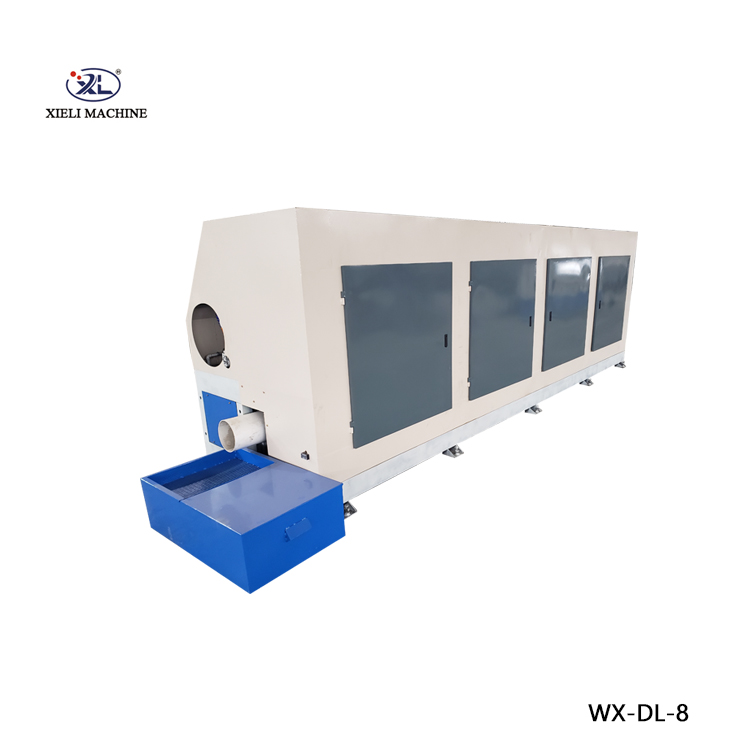

oem centerless grinder tiger stripe

1. Enhanced Surface Finish The unique patterns created during the grinding process result in improved surface finishes on workpieces. This is particularly important in industries where aesthetics and precision are crucial, such as automotive and aerospace manufacturing.

2. Increased Grinding Efficiency Tiger Stripe technology allows for more efficient material removal rates. The innovative wheel design promotes better chip removal, reducing the chances of overheating and extending the life of the grinding wheel.

3. Reduced Setup Time OEM centerless grinders incorporating Tiger Stripe technology require fewer adjustments and setups, minimizing downtime. This is especially beneficial in high-throughput environments, ensuring that production lines remain efficient and cost-effective.

4. Versatility Across Materials This technology has shown promise across a range of materials, including metals, plastics, and composites. The adaptability of Tiger Stripe technology makes it a valuable asset for manufacturers dealing with multiple substrates, reducing the need for specialized machinery.

5. Consistency and Repeatability The precision engineering behind OEM centerless grinders ensures that every part produced maintains a high level of consistency. This repeatability is essential for industries that demand tight tolerances and uniformity in their products.

Conclusion

As manufacturing processes continue to evolve, the reliance on advanced grinding solutions becomes increasingly important. OEM centerless grinders featuring Tiger Stripe technology represent a significant leap forward in machining capabilities. By offering enhanced surface finishes, increased efficiency, reduced setup times, versatility across materials, and consistent results, these machines are poised to meet the demands of modern industry head-on.

Investing in OEM centerless grinders equipped with Tiger Stripe technology not only ensures high-quality production but also supports the overarching goal of manufacturing excellence. As companies strive to innovate and remain competitive, leveraging such advancements in grinding technology will be key to their success. In this challenging landscape, the Tiger Stripe technology in OEM centerless grinders stands out as a vital tool for driving forward the future of precision manufacturing.