The Best Lidkoping Centerless Grinding Machine Revolutionizing Precision Engineering

In the realm of precision engineering, the lidkoping centerless grinding machine has emerged as a cutting-edge solution, successfully streamlining manufacturing processes across various industries

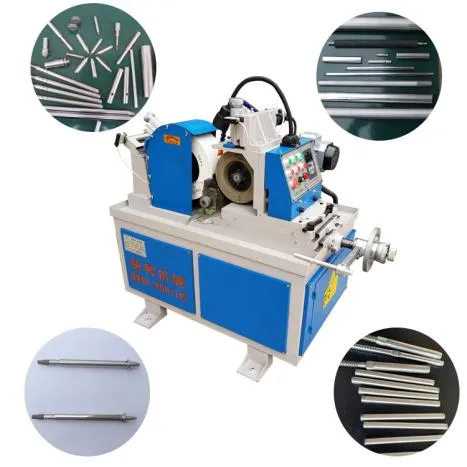

. Renowned for its efficiency and precision, this machine has become an indispensable tool for manufacturers focusing on high-volume production of cylindrical components.At the heart of the lidkoping centerless grinding machine is its unique design, which eliminates the need for a traditional workholding mechanism. Unlike conventional grinding machines that require fixtures to hold parts in place, the centerless approach allows workpieces to float freely between two grinding wheels. This innovative method significantly reduces setup time and enhances throughput, making it ideal for mass production scenarios.

One of the standout features of the lidkoping centerless grinding machine is its ability to achieve tight tolerances. Components can be ground to incredibly precise dimensions, often within microns. This level of accuracy is particularly crucial in industries such as automotive, aerospace, and medical device manufacturing, where even minute discrepancies can lead to significant functional issues. The lidkoping machine's advanced control systems enable operators to monitor and adjust grinding parameters in real time, ensuring consistent quality across batches.

best lidkoping centerless grinding machine

Another key advantage of the lidkoping centerless grinding machine is its versatility. It can effectively grind a variety of materials, including metals, polymers, and composites. This adaptability makes it suitable for different applications, from manufacturing shafts and pins to producing intricate parts for complex assemblies. The machine can handle various part sizes and shapes, catering to the diverse needs of modern manufacturing.

Moreover, advancements in technology have further enhanced the capabilities of lidkoping centerless grinding machines. Many models now come equipped with automated features, such as in-feed and through-feed systems, which allow for non-stop operation and reduced labor costs. The integration of smart manufacturing technologies, including IoT connectivity and data analytics, empowers operators to optimize machine performance and predictive maintenance, ultimately leading to reduced downtime and increased productivity.

In conclusion, the lidkoping centerless grinding machine stands out as a superior option for manufacturers aiming to enhance precision and efficiency. Its unique design, combined with state-of-the-art technology, positions it as a leader in the field of grinding machinery. As industries continue to evolve and demands for quality increase, the role of the lidkoping centerless grinding machine will undoubtedly become more prominent, driving advancements in manufacturing excellence. By embracing such innovative solutions, manufacturers can stay competitive in a rapidly changing market.