The Global Market for Steel Tube Polishing Machines A Focus on Exporters

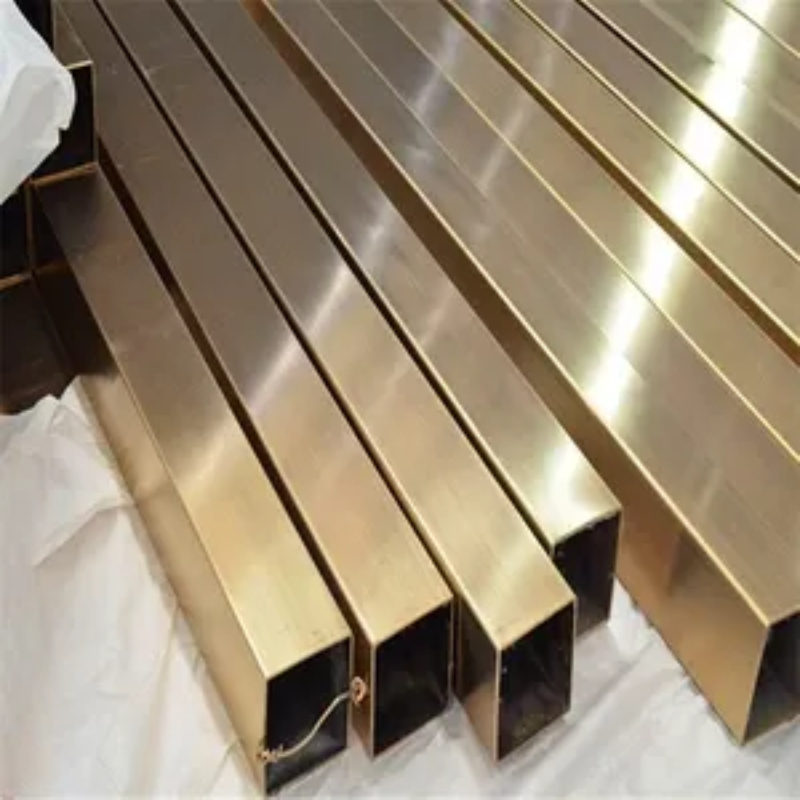

In the industrial landscape, steel tube polishing machines play a critical role in enhancing the aesthetic and functional qualities of steel products. These machines are essential for finishing processes, ensuring that steel tubes are smooth, free from defects, and ready for various applications in sectors such as construction, automotive, and manufacturing. As industries evolve and global demand for high-quality tubular products rises, the export market for steel tube polishing machines has gained significant momentum.

Understanding the Technology

Steel tube polishing machines employ advanced technology to achieve a polished finish on metal surfaces. These machines utilize various methods, including abrasive polishing, buffing, and chemical treatments, to remove imperfections and enhance surface qualities. The market is characterized by a range of machines, from manual setups to fully automated systems equipped with CNC (Computer Numerical Control) capabilities. This diversity caters to different production scales and operational needs, making them attractive to a wide array of industries.

Key Export Markets

The demand for steel tube polishing machines is not confined to any single region. Key exporters, primarily from countries like China, Germany, Japan, and the United States, are actively participating in the global market, responding to increasing international demand. As manufacturing hubs continue to emerge in developing nations, the need for efficient and reliable polishing machinery is expected to grow.

Asian countries, particularly China and India, have become significant players in the production and export of these machines. Their competitive pricing, combined with rapid technological advancements, makes them attractive in the global market. Chinese manufacturers, in particular, have established a reputation for producing cost-effective solutions without compromising quality.

Quality Standards and Innovation

steel tube polishing machine exporters

While pricing plays a crucial role, the quality of steel tube polishing machines is equally important for exporters. Stringent quality control measures and adherence to international standards are paramount in ensuring that products meet the expectations of clients across various industries. Many exporters invest heavily in research and development to innovate and improve their machines, ensuring enhanced performance and durability.

Technological advancements such as automation, IoT (Internet of Things) integration, and real-time monitoring systems are becoming commonplace in modern polishing machines. These innovations not only boost efficiency but also offer users the ability to gather valuable data for process optimization.

Challenges Faced by Exporters

Despite the positive outlook, exporters of steel tube polishing machines face several challenges. Fluctuations in raw material prices, trade tariffs, and geopolitical tensions can impact operational costs and market access. Furthermore, the rising trend toward sustainability is pushing companies to adapt their manufacturing processes to align with eco-friendly practices. Exporters are increasingly looking to incorporate energy-efficient technologies and reduce waste in machine production.

The Future Outlook

Looking ahead, the market for steel tube polishing machines is poised for growth. As industries pivot toward more sustainable and automated production processes, the demand for high-quality, efficient polishing machines will likely increase. Exporters who can leverage technology, maintain high-quality standards, and adapt to market shifts will find significant opportunities in the global arena.

In conclusion, the export landscape for steel tube polishing machines is vibrant, dynamic, and filled with potential. As various industries continue to expand and embrace technological innovations, collaborating with reliable exporters offers a pathway to achieving superior product quality and operational efficiency. The future for steel tube polishing machines and their exporters looks bright, driven by advancements in technology and a growing global market.