The Significance of SS Pipe Polishing Machines in Modern Manufacturing

In recent years, the manufacturing sector has witnessed significant advancements, particularly in processes that enhance the aesthetics and functionality of metal products. One such process is pipe polishing, which plays a crucial role in the finishing stages of stainless steel (SS) pipe production. As industries seek higher standards of quality and efficiency, the demand for dependable SS pipe polishing machine manufacturers has grown substantially.

Understanding SS Pipe Polishing Machines

SS pipe polishing machines are specialized devices designed to improve the surface finish of stainless steel pipes. Polishing is essential not only for aesthetic reasons but also for compliance with various industry standards. A smooth surface finish can significantly enhance corrosion resistance, improve fluid dynamics, and facilitate easier cleaning and maintenance.

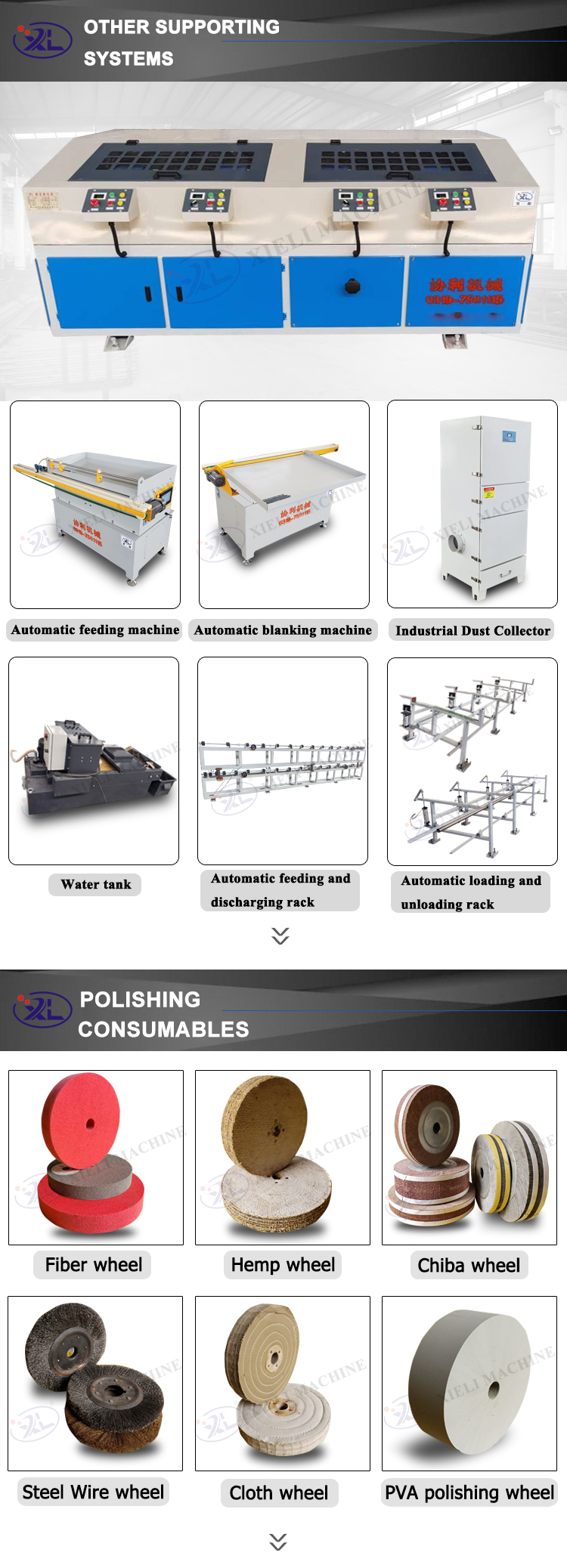

These machines utilize various methods—including mechanical buffing, vibratory polishing, and electro-polishing—to achieve desired finishes. The choice of method often depends on the specific requirements of the end product and its intended application. Mechanical buffing is effective for high-gloss finishes, while vibratory polishing is ideal for removing scale and rough edges. Electro-polishing, on the other hand, is particularly valued in sanitary applications due to its ability to smooth microscopic imperfections that can harbor bacteria.

The Role of Manufacturers

As the demand for high-quality SS pipe polishing machines continues to grow, manufacturers specializing in this equipment have emerged as key players in the market. These manufacturers are tasked with the design and production of innovative solutions that improve efficiency and reduce operational costs for pipe producers.

Leading manufacturers focus on several core aspects to enhance their product offerings

1. Quality and Durability High-quality materials and robust construction ensure the machines can withstand the rigors of daily operations. Manufacturers often utilize stainless steel components and advanced engineering techniques to enhance durability.

2. Technology Integration Modern SS pipe polishing machines incorporate the latest technological advancements, including automation, IoT capabilities, and precision control systems. Automation enhances productivity and consistency, while IoT integration allows for real-time monitoring and diagnostics, streamlining maintenance processes.

ss pipe polishing machine manufacturer

3. Versatility Manufacturers understand the varying needs of different industries. Therefore, they often design machines that can handle a range of pipe sizes and materials, allowing companies to adapt their workflows with ease. Customization options are also available, catering to specific customer preferences.

4. Sustainability With an increasing focus on environmental responsibility, many manufacturers are implementing sustainable practices in their production processes. This includes energy-efficient designs, reduced waste generation, and the ability to recycle consumables used during polishing.

Challenges and Solutions

Despite the advancements in SS pipe polishing technology, manufacturers face several challenges. The evolving market demands more efficient, cost-effective solutions while ensuring compliance with stringent quality standards. To address these challenges, manufacturers must invest in continuous research and development.

One prominent solution involves engaging in collaborative efforts with end-users to better understand their needs and feedback. This approach facilitates the development of tailored machines that not only meet but exceed industry expectations. Additionally, offering comprehensive training and support ensures customers can maximize the potential of their SS pipe polishing machines, leading to improved outcomes.

The Future of SS Pipe Polishing Machines

Looking forward, the future of SS pipe polishing machines appears promising. As industries like construction, automotive, and food processing continue to expand, so will the applications for polished stainless steel pipes. The integration of smart technology, artificial intelligence, and data analytics is likely to transform the way these machines operate, leading to even greater efficiency and precision.

Moreover, as sustainability continues to be a focal point for manufacturers, innovations aimed at minimizing environmental impact will become increasingly important. This includes not only energy-efficient designs but also the development of biodegradable polishing compounds and processes that minimize waste.

Conclusion

SS pipe polishing machines are integral to the production of high-quality stainless steel products. As the market continues to evolve, manufacturers must remain agile and responsive to the changing needs of their customers. By focusing on quality, innovation, versatility, and sustainability, they can ensure their machines contribute effectively to the efficiency and success of the manufacturing sector. Consequently, the SS pipe polishing industry is poised for significant growth and transformation in the coming years, benefiting manufacturers and consumers alike.