The Importance of ODM Stainless Steel Plate Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, the pursuit of high-quality finishes and precision engineering is paramount. Among the innovative machinery that support these goals, ODM stainless steel plate polishing machines play a crucial role. These machines have transformed how industries approach metal finishing, enhancing both aesthetic appeal and functional performance of stainless steel products.

Understanding ODM Technology

ODM stands for Original Design Manufacturer, a business model that allows companies to design and produce products based on specific customer requirements. In the context of stainless steel plate polishing machines, ODM technologies enable manufacturers to tailor machines specifically to their unique processes, enhancing efficiency and output quality. This customization is significant in an industry where standardization may not meet all client needs.

Applications of Stainless Steel Plate Polishing Machines

Stainless steel is a material favored for its corrosion resistance, strength, and aesthetic qualities. Industries such as construction, automotive, and food processing frequently utilize stainless steel components. Polishing machines ensure that these parts meet the high standards demanded by various applications.

These machines effectively remove surface imperfections, weld seams, and scratches, which can otherwise detract from the quality of stainless steel products. Moreover, polished surfaces exhibit enhanced resistance to corrosion and contamination, which is particularly critical in industries like food processing and healthcare.

Key Features and Benefits

ODM stainless steel plate polishing machines are equipped with advanced features that improve functionality. Grit-responsive polishing rollers, automated feeding systems, and programmable logic controllers (PLC) allow for precise control over the polishing process. Such features contribute to a consistent finish while reducing the likelihood of defects.

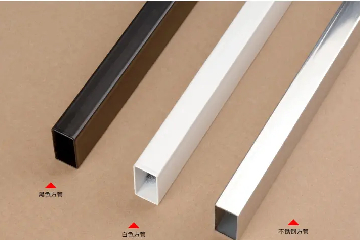

odm stainless steel plate polishing machine

The benefits of investing in ODM polishing machines extend beyond just aesthetic improvements. A polished surface can significantly enhance the lifespan of stainless steel products by minimizing the accumulation of contaminants and reducing wear. Consequently, manufacturers experience lower operational costs due to decreased downtime and enhanced efficiency.

Customization for Unique Needs

One of the standout advantages of ODM technology is the customization it offers. Companies often have specific polishing requirements based on their product lines. ODM manufacturers work closely with clients to create machines that match their operational needs, from the size and shape of the stainless steel plates to the desired finish.

This level of customization enables manufacturers to become more agile and responsive to market demands. For example, a company specializing in creating custom automotive parts can collaborate with an ODM to develop a machine that optimizes the polishing process for intricately designed components without compromising on quality.

Environmental Considerations

With an increasing emphasis on sustainability in manufacturing, many modern ODM stainless steel plate polishing machines are designed with environmental considerations in mind. These machines often incorporate features that reduce waste and energy consumption, aligning with the growing trend towards eco-friendly manufacturing practices.

For instance, recycled materials may be used in construction, and advanced technology can enable optimal use of polishing compounds, thereby minimizing environmental impact. Investing in such machinery not only improves operational efficiency but also enhances a company's reputation as a socially responsible organization.

Conclusion

In conclusion, ODM stainless steel plate polishing machines are essential tools in modern manufacturing. They deliver high-quality finishes, ensure durability, and enable customization that meets specific industry needs. As companies continue to seek out innovative solutions to enhance productivity and sustainability, the role of these advanced machines will only grow in importance. Embracing such technology can provide manufacturers with a competitive edge in an increasingly demanding market, ultimately leading to greater customer satisfaction and business success.