The Rise of Affordable Centerless Cylindrical Grinding Machines

In the world of precision engineering, centerless cylindrical grinding machines have emerged as essential tools for high-volume production, offering unmatched efficiency and accuracy. However, the steep costs associated with acquiring these machines often limit their use to large-scale operations. Recently, there has been a surge of interest in cheap centerless cylindrical grinding machines, leading to a revolution in manufacturing processes for small to medium-sized enterprises.

Understanding Centerless Grinding

Centerless grinding is a machining process that relies on the precise positioning of the workpiece between two grinding wheels a regulating wheel and a grinding wheel. Unlike traditional cylindrical grinding, where the workpiece is held between centers, centerless grinding does not require any clamping or fixturing, resulting in faster processing times and improved throughput. This method is particularly effective for producing small cylindrical parts with tight tolerances, making it invaluable in industries such as automotive, aerospace, and medical device manufacturing.

Affordable Solutions

The recent trend toward budget-friendly centerless cylindrical grinding machines is largely driven by advancements in technology and increased competition among manufacturers. Several companies recognized the need for more accessible machinery that doesn't compromise on quality. As a result, industries can now find cost-effective options without sacrificing performance.

These machines are typically designed with simplified features that retain core functionalities while cutting down on unnecessary complexity, which ultimately lowers production costs. By utilizing modern manufacturing techniques, such as CNC automation and intelligent controls, manufacturers have been able to produce reliable machines that cater to the needs of smaller businesses.

Key Benefits of Cheap Centerless Cylindrical Grinding Machines

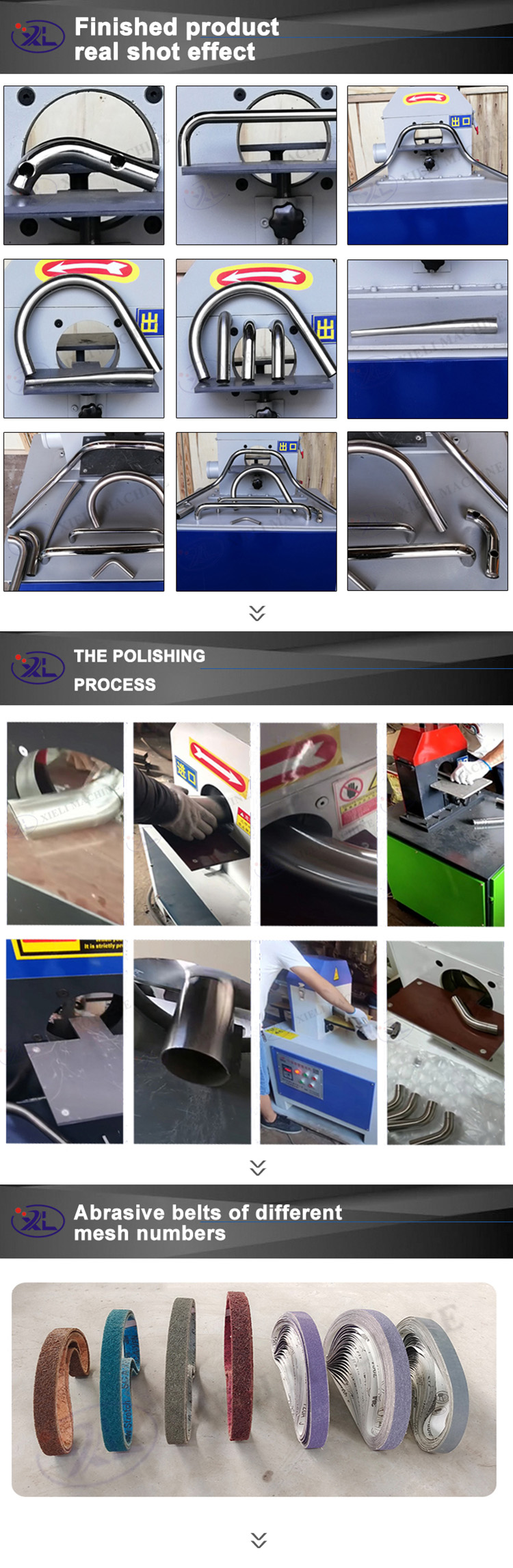

cheap centerless cylindrical grinding machine

1. Cost Efficiency The most apparent advantage of budget-friendly centerless grinding machines is their lower purchase price, making them an attractive option for businesses with limited capital. This access encourages innovation and competitiveness among smaller firms.

2. Space-Saving Design Many of these machines come in compact sizes, making them suitable for facilities with limited shop floor space. This adaptability allows even small operations to integrate centerless grinding into their production line without extensive renovations.

3. Ease of Use Affordable models often feature user-friendly interfaces, allowing operators to quickly learn and adapt to the system. The reduced learning curve increases productivity and reduces downtime.

4. Versatility Low-cost centerless grinding machines can often handle a variety of materials, including metals and plastics, making them suitable for diverse applications. This versatility is crucial for firms that work on multiple projects simultaneously.

5. Enhanced Productivity The high-speed capabilities of these machines make them ideal for high-volume production runs. Increased throughput translates to lower per-unit costs, which is vital for maintaining competitiveness in the market.

Conclusion

The emergence of cheap centerless cylindrical grinding machines is reshaping the landscape of precision machining. By providing accessible, efficient, and versatile grinding solutions, these machines empower small and medium-sized enterprises to improve their manufacturing processes significantly. As technology continues to advance and prices remain competitive, the adoption of centerless grinding is expected to rise, further democratizing access to this essential machining process. This shift not only fosters innovation but also strengthens industry competitiveness, paving the way for a dynamic and resilient manufacturing future.