Centerless Valve Grinder for Sale An Overview of Manufacturers and Market Trends

In the world of precision engineering and automotive manufacturing, the need for high-quality grinding tools is paramount. Among these tools, centerless valve grinders have emerged as indispensable machinery for achieving precise tolerances in the production of engine components. This article delves into the significance of centerless valve grinders, the leading manufacturers in the industry, and current market trends.

Understanding Centerless Grinding

Centerless grinding is a manufacturing process that allows for the efficient grinding of workpieces without the need for a fixed center. This technique is particularly beneficial for producing cylindrical components – including valves for various engines. The centerless grinder consists of two wheels, the grinding wheel and the regulating wheel, which work together to provide the necessary precision and orientation for the workpiece.

The advantages of centerless grinding include high throughput, reduced cycle times, and the ability to grind multiple parts simultaneously. For industries focusing on mass production, such as automotive and aerospace, having a reliable centerless grinder can significantly enhance productivity and ensure that traditional difficulties of misalignment and wear are minimized.

Leading Manufacturers

The centerless valve grinder market is populated by several prominent manufacturers, each offering unique features and specifications designed to meet specific industry needs.

1. Cincinnati Milacron Renowned for its durable and high-performance machines, Cincinnati Milacron offers models equipped with advanced CNC technology, enhancing precision and automation in the grinding process.

2. Royal Master Grinders This company specializes in high-quality centerless grinding machines and has gained a reputation for its customizable solutions. Their grinders are particularly known for their compact designs and efficiency.

3. Koyo Machinery Koyo provides a range of centerless grinding machines that cater to varied applications. Their machines are recognized for delivering consistent quality in high-precision environments.

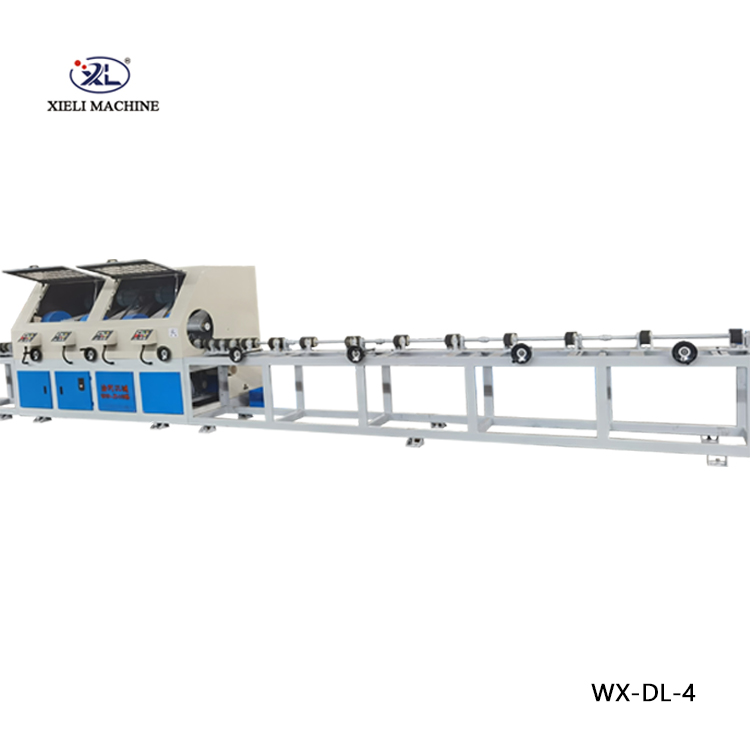

centerless valve grinder for sale manufacturers

4. Acme Manufacturing Focusing on the integration of automation with centerless grinding, Acme's machines are designed to streamline production processes while maintaining superior tolerances.

5. Tschudin A Swiss manufacturer famous for its slick designs, Tschudin’s grinders are engineered for high precision and are often used in both high-volume production and specialized projects.

Market Trends

As industries evolve, so do the demands on grinding technologies. The current market for centerless valve grinders exhibits several notable trends

- Automation and Industry 4.0 The incorporation of automation technology and smart manufacturing principles is reshaping the pathways of valve production. Many new models are equipped with advanced software and IoT capabilities, allowing for real-time monitoring and enhanced operational efficiency.

- Sustainability With increasing focus on sustainable manufacturing practices, manufacturers are innovating to produce machines that minimize waste and energy consumption. Eco-friendly grinding fluids and recyclable materials are gaining importance in the design and production of centerless grinders.

- Customization and Flexibility There is a growing demand for adaptable grinding machines capable of accommodating various valve shapes and sizes. Manufacturers are responding by offering customizable features that allow operators to adjust grinding parameters quickly and efficiently.

- Quality over Quantity As industries move toward quality-centric production, the need for exceptionally precise grinders is paramount. This trend has led to a surge in demand for high-end machines that ensure exact tolerances and surface finishes.

Conclusion

The centerless valve grinder market is vibrant, driven by technological advancements and the diverse needs of manufacturing industries. As production demands evolve, the focus on automation, sustainability, and customization in grinder design will continue to play a crucial role in shaping the industry. Companies looking to invest in new centerless valve grinders should carefully evaluate the various manufacturers available, assessing their offerings to ensure they choose a solution that aligns with their operational goals and quality standards.