Centerless Grinder Rebuilders Exporting Precision and Quality

In the world of manufacturing, precision is paramount. One of the most critical tools in this realm is the centerless grinder. This machine plays a vital role in producing cylindrical parts with exacting tolerances, making it indispensable in various industries, from automotive to aerospace. For manufacturers looking to optimize their operations, the role of centerless grinder rebuilders cannot be overstated, especially those involved in exporting these finely-tuned machines.

Understanding Centerless Grinding

Centerless grinding is a method of removing material from a workpiece. Unlike traditional grinding, where the workpiece is held between two centers, the centerless grinding process requires no such fixtures. Instead, the workpiece is held in place by a combination of the grinding wheel, the regulating wheel, and the workblade. This setup allows for continuous operation and the processing of parts in a highly efficient manner.

While centerless grinders are built to endure rigorous operations, wear and tear are inevitable. This is where the expertise of centerless grinder rebuilders comes into play. These professionals specialize in refurbishing and restoring older machines to extend their lifespan and improve performance, ultimately contributing to a manufacturer's bottom line.

The Role of Centerless Grinder Rebuilders

Centerless grinder rebuilders are highly skilled technicians who understand the complexities of these sophisticated machines. Their services typically involve disassembling the grinder, assessing and replacing worn-out components, and recalibrating the machine to meet original specifications. This meticulous process ensures that the grinder will operate as efficiently and effectively as a new unit, at a fraction of the cost.

The rebuilding process not only revitalizes the machine's functionality but also significantly extends its economic life. For companies that rely on high-stakes manufacturing processes, investing in rebuilding services rather than purchasing new machinery can lead to substantial cost savings. Moreover, the refurbished machines can maintain the precision and quality expected in today's competitive market.

Exporting Quality Machines

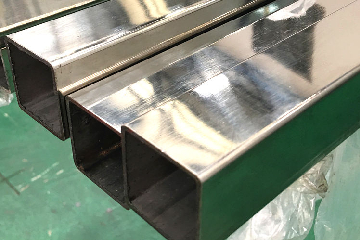

centerless grinder rebuilders exporter

The global market for centerless grinders is vast, and many rebuilders have established themselves as key exporters of these machines. By adhering to stringent quality standards and leveraging advanced technologies, these companies have positioned themselves as leaders in the industry.

Exporting centerless grinders involves navigating a complex landscape of regulations, shipping logistics, and customer expectations. Rebuilders must ensure that their machines comply with the export laws of their home country as well as the import regulations of the destination country. This requires a deep understanding of international standards and the ability to adapt their offerings accordingly.

Additionally, centerless grinder rebuilders must maintain a strong focus on quality assurance. Each refurbished machine must undergo rigorous testing and quality control processes to ensure that it meets the high standards expected by international clients. Rebuilders who prioritize quality not only strengthen their reputation but also foster long-term relationships with clients across the globe.

Innovations in the Industry

The centerless grinding industry continues to evolve, with technological advancements playing a significant role in shaping its future. Modern rebuilders are increasingly incorporating automation and digital technologies into their operations. For instance, the integration of computer numerical control (CNC) systems enables more precise and consistent grinding processes, which are highly sought after in various sectors.

Moreover, the trend towards sustainable manufacturing practices is also making its mark on the industry. Rebuilders are now incorporating eco-friendly materials and processes, focusing on minimizing waste and energy consumption. As businesses worldwide become more environmentally conscious, partnering with rebuilders who prioritize sustainability can be a critical factor for manufacturers.

Conclusion

Centerless grinder rebuilders play a crucial role in enhancing the efficiency and longevity of grinding machines. As the demand for precision manufacturing continues to grow, these specialists not only contribute to the sustainability of existing equipment but also position themselves as valuable partners in the global marketplace. By prioritizing quality, innovating with technology, and adhering to rigorous standards, centerless grinder rebuilders are set to thrive in an increasingly competitive landscape. Their commitment to excellence ensures that manufacturers can continue to rely on these essential tools to drive productivity and innovation in their operations.