Understanding the Role of a Centerless Grinder Operator

In the realm of precision manufacturing, the role of a centerless grinder operator is crucial. This position involves the operation of specialized machinery that grinds and shapes materials without the need for a fixed center. Centerless grinding is predominantly utilized for manufacturing small components such as pins, shafts, and rollers, which require outstanding dimensional accuracy and surface finish.

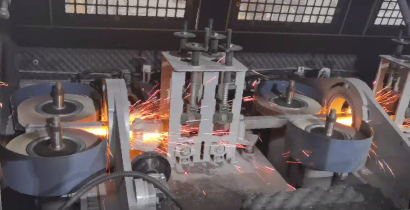

The process of centerless grinding differs fundamentally from traditional grinding methods. In a centerless grinder, the workpiece is held in place by two wheels. The grinding wheel performs the grinding action while the regulating wheel controls the feed and speed of the workpiece. This setup allows for high-volume production runs since parts can be fed through the machine continuously, making it highly efficient for manufacturers focusing on high precision.

A centerless grinder operator plays a vital role in ensuring the grinding process runs smoothly. Responsibilities include setting up the machine, adjusting the wheels, and monitoring the grinding process to maintain quality standards. Operators must possess a keen eye for detail as they frequently inspect parts for surface quality and dimensional accuracy. Knowledge of various materials and grinding techniques is essential, as different components may require distinct parameters to achieve optimal results.

centerless grinder operator company

Safety is another critical aspect of a centerless grinder operator's responsibilities. Operators must be adept in following safety protocols to prevent accidents, as the machinery operates at high speeds. Proper training and adherence to regulations are essential to mitigate risks associated with operating heavy machinery.

Furthermore, the role demands strong problem-solving skills. If a machine malfunctions or if parts do not meet specifications, the operator must troubleshoot issues efficiently. This could involve recalibrating the machine or making adjustments to the grinding process.

In conclusion, becoming a proficient centerless grinder operator requires a blend of technical skills, attention to detail, and a commitment to safety. The efficiency brought about by these operators not only enhances productivity but also ensures that the end products meet the rigorous quality standards expected in the manufacturing industry. As technology evolves, the operator's role will continue to adapt, making it an exciting field for those interested in precision engineering and manufacturing.