The Rise of Stainless Steel Square Pipe Polishing Machine Exporters

In today’s rapidly evolving manufacturing landscape, the demand for high-quality stainless steel products continues to surge. Among these products, stainless steel square pipes are widely utilized in various industries such as construction, automotive, and food processing. To meet this demand, the role of stainless steel square pipe polishing machines has become crucial. These machines are not only essential for enhancing the aesthetic appeal of stainless steel products but also for improving their durability and resistance to corrosion. As a result, the export market for stainless steel square pipe polishing machines is witnessing significant growth.

Importance of Polishing Machines

Polishing machines serve a vital function in the production of stainless steel square pipes. They remove surface imperfections and oxidation, leading to a smoother and shinier finish. This process not only enhances the appearance of the pipes but also increases their resistance to contaminants and rust, thereby extending their lifespan. Industries that rely on these pipes demand high standards, as stainless steel products often encounter harsh environments. Polishing machines equipped with advanced technology ensure that the pipes meet these rigorous specifications.

Key Features of Stainless Steel Square Pipe Polishing Machines

Modern polishing machines come with several advanced features that enhance their efficiency and effectiveness. One of the critical components is the abrasive technology used, which plays a significant role in determining the final finish of the stainless steel pipes. Available in various grades, these abrasives can be tailored according to specific requirements. Additionally, automation has transformed the polishing process; many machines are now equipped with robotics that not only improve speed but also ensure uniformity in the finished product.

Another significant feature is the ability to handle different pipe sizes and shapes. Some advanced polishing machines can process multiple sizes interchangeably, which is beneficial for manufacturers dealing with diverse product lines. Furthermore, energy efficiency has become a priority for both manufacturers and consumers, prompting the development of machines that consume less power while delivering superior performance.

The Export Market Landscape

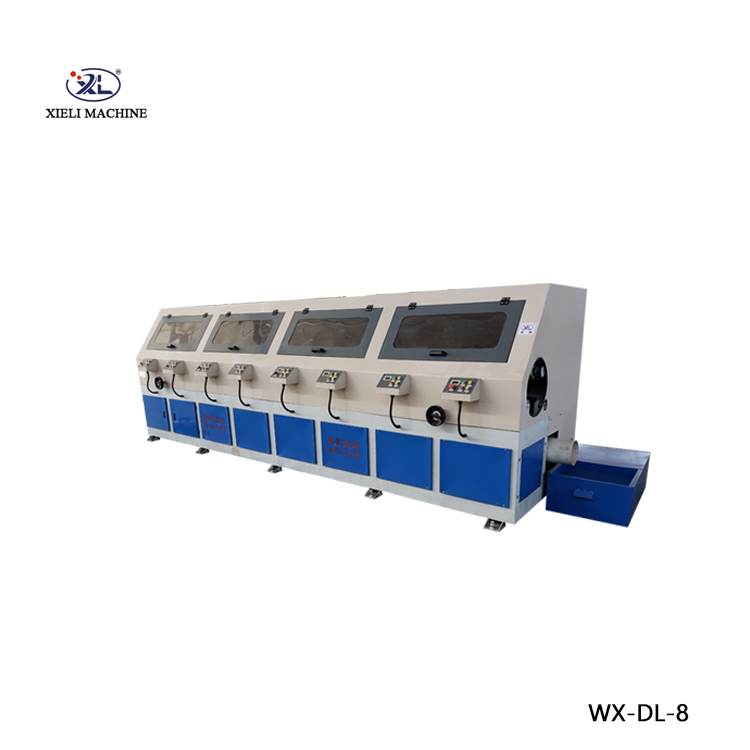

stainless steel square pipe polishing machine exporter

As demand for stainless steel square pipe polishing machines grows, so does the export market. Countries known for heavy industrialization, such as China, Italy, and Germany, have established themselves as prominent exporters in this arena. These countries leverage their advanced manufacturing capabilities and specialized expertise to produce high-quality machines that are sought after worldwide.

China has emerged as a key player in the export of polishing machines due to its competitive pricing and robust production capabilities. Manufacturers in China are investing in research and development to produce more efficient and durable machines, further solidifying their position in the market. European manufacturers, on the other hand, are known for their high-quality engineering and innovation. Their machines often come equipped with cutting-edge technology and are built for longevity, making them a preferred choice for businesses prioritizing quality over cost.

Challenges and Future Outlook

Despite the strong growth in the export market, there are several challenges that exporters face. Intense competition, particularly from emerging economies, demands continual innovation and improvement in product offerings. Additionally, fluctuating raw material costs can impact pricing strategies, making it necessary for exporters to adopt flexible pricing models to remain competitive.

Looking ahead, the future of stainless steel square pipe polishing machine exporters appears promising. With industries increasingly prioritizing sustainable practices, machines that promote energy efficiency and reduce waste will likely gain traction in the market. Furthermore, the rise of Industry 4.0 and the Internet of Things (IoT) presents an opportunity for manufacturers to integrate smart technologies into their machines, enabling real-time monitoring and predictive maintenance.

Conclusion

The export market for stainless steel square pipe polishing machines is poised for continued growth due to the increasing demand for high-quality stainless steel products across various sectors. With advancements in technology and a focus on efficiency and sustainability, exporters who adapt to these trends will likely thrive. As the industry evolves, staying informed and innovative will be key for businesses looking to establish a presence in this competitive market, ultimately contributing to the global manufacturing landscape.