The Importance of High-Quality Stainless Steel Square Pipe Polishing Machines

In the rapidly-evolving metal fabrication industry, the quality of equipment plays a crucial role in the overall outcome of production processes. Among various types of machinery, high-quality stainless steel square pipe polishing machines stand out for their importance in enhancing the aesthetic and functional properties of metal products. This article will explore the significance of these machines, their features, and the benefits they bring to manufacturers and end-users alike.

Understanding Stainless Steel Square Pipes

Stainless steel square pipes are widely used in various industries, including construction, automotive, and furniture manufacturing. Their durability, corrosion resistance, and aesthetic appeal make them a preferred choice for many applications. However, the production process of these pipes leaves them with rough edges and an unattractive finish that may not be suitable for customer demands. This is where polishing machines come into play.

The Role of Polishing Machines

Polishing machines are designed to enhance the surface finish of stainless steel square pipes. A well-polished surface not only improves the visual appeal of the product but also offers additional advantages, such as enhanced corrosion resistance and easier maintenance. The polishing process involves removing surface imperfections and achieving a smooth, shiny finish, which is particularly important for items that will be visible to consumers.

Key Features of High-Quality Polishing Machines

When selecting a stainless steel square pipe polishing machine, several key features should be considered

1. Versatility High-quality machines are designed to handle various sizes and thicknesses of square pipes. This versatility enables manufacturers to use a single machine for multiple projects, reducing costs and increasing efficiency.

2. Advanced Technology Modern polishing machines incorporate advanced technologies, such as automatic feeding systems and programmable controls, which allow for consistent polishing results without the need for extensive manual intervention.

3. Durability Given the harsh environments in which these machines often operate, it is vital that they are built with robust materials and components. A high-quality polishing machine will have a longer lifespan and require less maintenance, ultimately providing better return on investment.

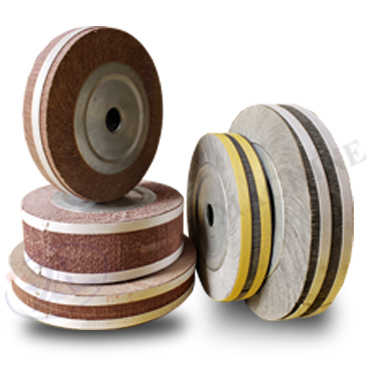

high quality stainless steel square pipe polishing machine

4. Precision Precision is essential in polishing operations to achieve the desired finish. High-quality machines provide consistent results, allowing manufacturers to meet strict quality standards while minimizing material waste.

5. Safety Features In industries where machinery is extensively used, safety cannot be overlooked. High-quality polishing machines come equipped with various safety features, such as emergency shut-off systems and protective guards, to ensure operator safety during use.

Benefits of Using High-Quality Polishing Machines

The implementation of high-quality stainless steel square pipe polishing machines can yield significant benefits for manufacturers

- Enhanced Product Quality The improved finish on polished pipes meets customer expectations more effectively, leading to higher satisfaction and repeat business.

- Increased Efficiency Faster processing times due to automation and advanced technology result in higher productivity levels, allowing manufacturers to increase their output without compromising quality.

- Cost-Effectiveness By investing in high-quality machinery, manufacturers can reduce long-term operational costs related to maintenance and repairs. Furthermore, the consistency in product quality reduces the likelihood of product returns due to defects.

- Competitive Edge In a competitive market, the ability to deliver high-quality products quickly and efficiently can differentiate a business from its competitors, opening up new market opportunities.

Conclusion

As industries continue to demand high-quality stainless steel products, the need for effective polishing solutions becomes increasingly clear. High-quality stainless steel square pipe polishing machines offer numerous benefits, including enhanced product quality, increased efficiency, and cost-effectiveness. Investing in such technology not only meets market demands but also sets a foundation for long-term business success. As manufacturers continue to innovate, the role of polishing machines will remain pivotal in producing top-notch stainless steel products that satisfy both personal and industrial needs.