The Importance of OEM Inner Wall Polishing Machines in Modern Manufacturing

In the current landscape of manufacturing and production, the pursuit of quality and precision has never been more critical. One of the pivotal tools in achieving such high standards is the OEM (Original Equipment Manufacturer) inner wall polishing machine. This specialized machinery plays a vital role in various industries, including automotive, aerospace, and electronics, where the flawless finish of inner surfaces is paramount.

Understanding OEM Inner Wall Polishing Machines

At its core, an OEM inner wall polishing machine is designed to smooth and polish the inner surfaces of cylindrical components. These components can include pipes, tubes, and other machined parts that require a high level of finish to ensure performance and longevity. The polishing process reduces surface roughness and enhances the component's aesthetic appeal while also making it more resistant to corrosion and wear.

The term OEM refers to manufacturers who provide their products directly to other companies. In this context, an OEM polishing machine may either be produced by the company or licensed from another entity. This allows companies to maintain control over their supply chain and ensures that the machinery meets specific industry standards and requirements.

The Benefits of Inner Wall Polishing

There are several advantages to utilizing inner wall polishing machines in production. First and foremost is the improvement in product quality. A polished inner wall reduces friction and turbulence within any fluid system, leading to enhanced efficiency, especially in hydraulic systems. This is crucial in industries such as automotive engineering, where the performance of fuel lines and lubrication systems directly impacts engine efficiency and lifespan.

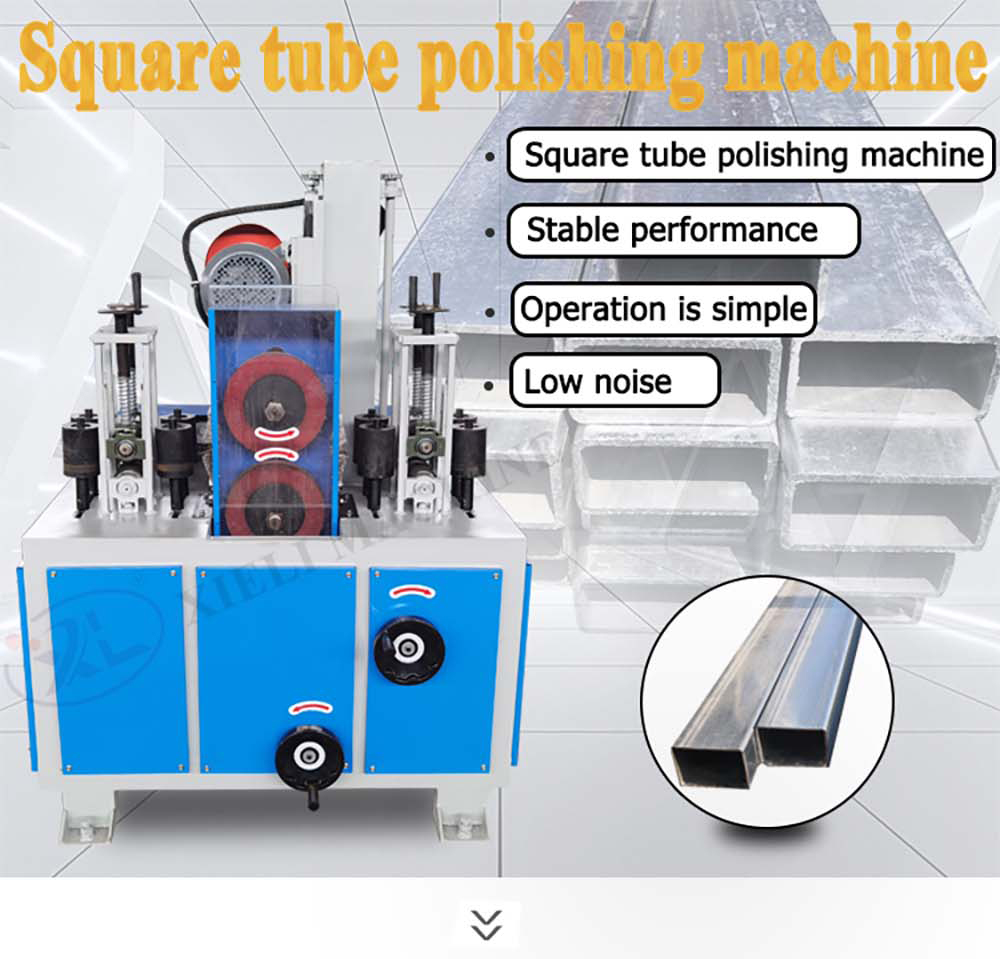

oem inner wall polishing machine

Moreover, polishing can significantly extend the lifespan of components. By eliminating surface imperfections, manufacturers can prevent issues related to corrosion and fatigue. This results in lower maintenance costs and minimizes the likelihood of operational downtimes, ultimately contributing to a more profitable manufacturing process.

Technological Advancements in Polishing Machines

Modern OEM inner wall polishing machines are equipped with advanced technologies that enhance their capabilities. Many of these machines now feature automated systems that not only control the polishing process but also monitor it in real-time. This automation leads to higher consistency in results and allows operators to produce high-volume runs with minimal risk of human error.

Additionally, new polishing techniques, such as ultrasonic and robotic polishing, have emerged in the market. Ultrasonic polishing employs high-frequency vibrations to remove material from the inner walls, achieving a superior finish in less time compared to traditional methods. Robotic polishing systems offer unparalleled precision and can operate in environments that may be hazardous for human workers, further emphasizing the versatility of modern polishing machines.

Investment in Quality

Investing in an OEM inner wall polishing machine is not merely a decision centered on cost; it reflects a commitment to quality and efficiency. While the initial outlay may be significant, the long-term benefits in terms of reduced maintenance costs, improved product performance, and increased customer satisfaction can far outweigh these expenses.

In conclusion, the role of OEM inner wall polishing machines in modern manufacturing cannot be overstated. As industries continue to evolve and the demand for quality remains high, these machines provide a necessary solution for ensuring that inner surfaces meet the required standards. By embracing the advancements in polishing technology and recognizing the importance of professional-grade equipment, manufacturers can significantly enhance their production capabilities and maintain a competitive edge in the market. Thus, the future of manufacturing is not only about output volume but also about the quality of each component produced, and OEM inner wall polishing machines are at the forefront of this transformation.