The Revolution of Manufacturing OEM Centerless Belt Grinding and Polishing Machines

In the world of precision engineering and manufacturing, the demand for high-quality surface finishes and dimensional accuracy is greater than ever. One of the standout solutions in this arena is the OEM (Original Equipment Manufacturer) centerless belt grinding and polishing machine. These advanced machines have revolutionized the way manufacturers approach metal finishing, offering unparalleled efficiency, consistency, and precision.

Understanding Centerless Belt Grinding

Centerless belt grinding is a process that involves the removal of material from the outer surface of a workpiece using abrasive belts without the need for a dedicated setup that includes centers or fixtures. This process can significantly improve the overall efficiency of the grinding operation. With the workpiece being fed through a controlled abrasive system, the machine is capable of producing parts with minimal setup times and reduced labor costs.

One of the primary advantages of centerless grinding is its ability to process parts of varying sizes and shapes with remarkable consistency. Whether you're working with rods, tubes, or any cylindrical objects, these machines excel at achieving tight tolerances and a superior surface finish. The OEM designs incorporate innovative technologies that enhance the grinding process, ensuring that manufacturers can achieve optimum results with every run.

The Role of Polishing in Metal Finishing

Polishing is another crucial aspect of metal finishing that is seamlessly integrated into the functionality of these machines. While grinding removes material to provide a smooth surface, polishing further enhances that surface quality, achieving a mirror-like finish. This is particularly important in industries such as automotive, aerospace, medical, and decorative applications where aesthetics and performance are equally critical.

OEM centerless belt grinding and polishing machines come equipped with specialized polishing belts designed to work in tandem with the grinding process. This integration allows for a streamlined workflow where grinding and polishing can occur in a single operation, saving both time and resources. The automation of these processes minimizes human errors and ensures a consistent finish across all produced parts.

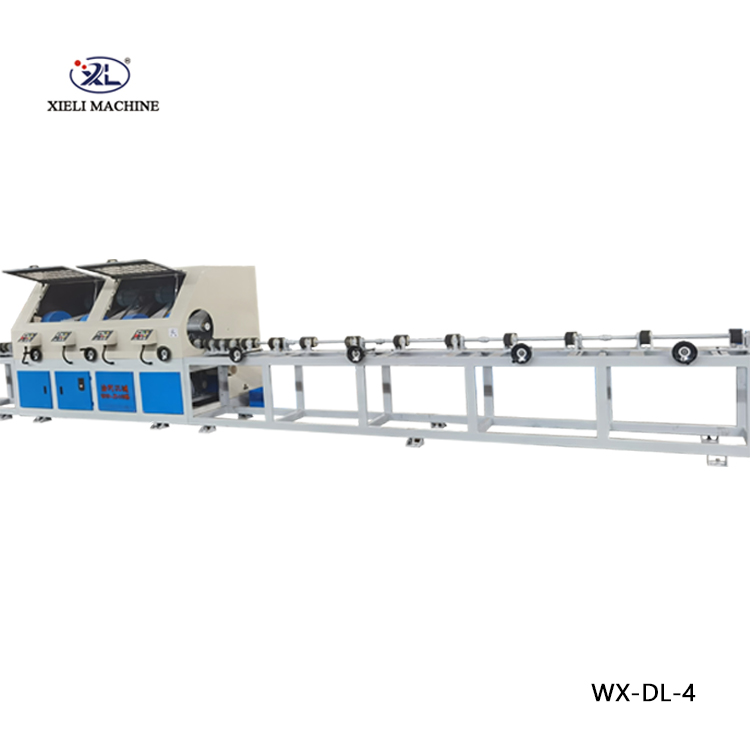

oem centerless belt grinding polishing machine

Customization and Versatility

Another significant benefit of OEM machines is their ability to be customized to meet specific operational needs. Manufacturers can tailor the machine settings, belt types, and polishing parameters according to the material being processed and the desired finish. This versatility is essential for companies involved in multiple industries, as it allows them to adapt quickly to changing market demands without investing in new equipment.

For businesses focused on reducing waste and enhancing efficiency, such customization options enable resources to be allocated more effectively. The right configuration can lead to reduced cycle times and improved throughput, which directly impacts the bottom line.

Sustainability and Industry 4.0

As industries become more conscious of their environmental impact, the efficiency of OEM centerless belt grinding and polishing machines contributes to sustainable manufacturing practices. These machines consume less energy and produce less waste than traditional methods, aligning with the industry's move towards greener operations.

Additionally, the integration of smart technologies into these machines, aligning with Industry 4.0 principles, allows for real-time monitoring and data collection. Manufacturers can gain insights into their processes, enabling predictive maintenance and further improving overall productivity.

Conclusion

The OEM centerless belt grinding and polishing machine represents a significant advancement in the manufacturing sector, combining efficiency, precision, and customization. Manufacturers looking to enhance their production capabilities, reduce waste, and deliver high-quality finished products should consider these machines as a core component of their operations. As industries continue to evolve with technological advancements, embracing innovative solutions like these will be key to staying competitive in a global market.