Understanding the OEM Table Top Centerless Grinder

In the realm of precision machining, the OEM Table Top Centerless Grinder stands out as a vital tool for manufacturers seeking efficiency and accuracy in their grinding processes. This equipment is designed to provide exceptional performance in a compact form, making it ideal for small workshops, educational institutions, and even larger manufacturing units looking to maximize their productivity.

What is a Centerless Grinder?

A centerless grinder is a type of cylindrical grinding machine that removes material from a workpiece to achieve a desired diameter and surface finish. Unlike traditional surface grinders, centerless grinders do not require the workpiece to be mounted between centers or chucks. Instead, the workpiece is supported by a combination of a grinding wheel and a work rest blade, allowing for continuous operation and increased throughput.

Key Features of the OEM Table Top Centerless Grinder

1. Compact Design One of the primary advantages of the OEM Table Top Centerless Grinder is its compact size. Designed to sit on a workbench or table, it occupies minimal floor space while still offering powerful grinding capabilities. This makes it suitable for small workshops and labs where space is at a premium.

2. User-Friendly Interface The grinder is equipped with an intuitive control panel that simplifies operation for users of all skill levels. Easy-to-understand settings and adjustments make it accessible for both beginners and experienced machinists.

3. Versatility The OEM Table Top Centerless Grinder can handle a variety of materials, including metals, plastics, and composites. It is suitable for grinding a wide range of workpiece shapes and sizes, making it a versatile addition to any machining operation.

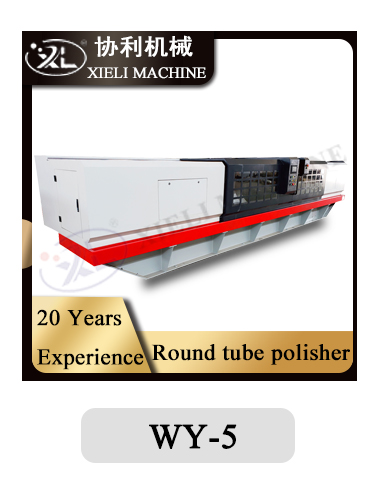

oem table top centerless grinder

4. Precision and Accuracy With precision bearings and motor controls, the OEM grinder ensures accurate alignment and consistent grinding results. This high level of accuracy is essential for industries where tight tolerances are required, such as aerospace, automotive, and medical device manufacturing.

5. Cost-Effectiveness Investing in an OEM Table Top Centerless Grinder can lead to significant cost savings over time. Its efficient design reduces material waste, while the high-speed operation increases productivity, allowing businesses to meet deadlines without sacrificing quality.

Applications of the Table Top Centerless Grinder

The OEM Table Top Centerless Grinder finds applications across various industries. It is commonly used for grinding small-diameter components such as rods, tubes, and pins. These components are often required in automotive parts, electrical connectors, and other precision instruments. Moreover, the tool is also an excellent choice for research and development projects where prototyping or experimental machining is essential.

Maintenance and Care

To ensure the longevity and optimum performance of the OEM Table Top Centerless Grinder, regular maintenance is crucial. Users should keep the machine clean and free of debris, check the alignment of the grinding wheel periodically, and ensure that all moving parts are lubricated. Following the manufacturer’s guidelines for oil changes and component replacements will also contribute to the machine’s durability and reliability.

Conclusion

The OEM Table Top Centerless Grinder is an indispensable asset to any production environment requiring precision grinding. With its compact design, user-friendly features, and versatility, it stands as a testament to innovative engineering in machining technology. Whether for small-scale operations or larger enterprises, this grinder not only enhances productivity but also ensures that components meet the stringent quality standards demanded by today’s industries. Investing in such a tool not only streamlines the grinding process but also propels businesses toward success in a competitive market.