Custom 2024x24 Centerless Grinder Revolutionizing Precision Machining

In the realm of precision machining, the importance of high-quality grinding equipment cannot be overstated. Among the most crucial machines in this industry is the centerless grinder. Specifically, the Custom 2024x24 Centerless Grinder has emerged as a game-changing solution for manufacturing operations seeking efficiency, accuracy, and versatility.

What is a Centerless Grinder?

A centerless grinder is a type of grinding machine that does not use a spindle to hold the workpiece in place. Instead, it relies on the interaction between a grinding wheel and a regulating wheel to control the position of the workpiece during the grinding process. This unique design enables continuous operation, allowing for the grinding of multiple parts without the need for constant set-up changes.

The Advantages of the Custom 2024x24 Centerless Grinder

The Custom 2024x24 Centerless Grinder is designed to accommodate specific needs of various industries. Here are several key advantages that make it a practical investment

1. Precision Engineering The centerless grinder features advanced engineering, ensuring that workpieces are machined to exact specifications. The machine is equipped with high-quality grinding wheels that provide superior surface finishes and maintain tight tolerances.

2. Increased Throughput With its continuous grinding operation, the Custom 2024x24 dramatically increases throughput compared to traditional grinding methods. This is particularly beneficial for businesses that require large batches of identical parts to be produced in a timely manner.

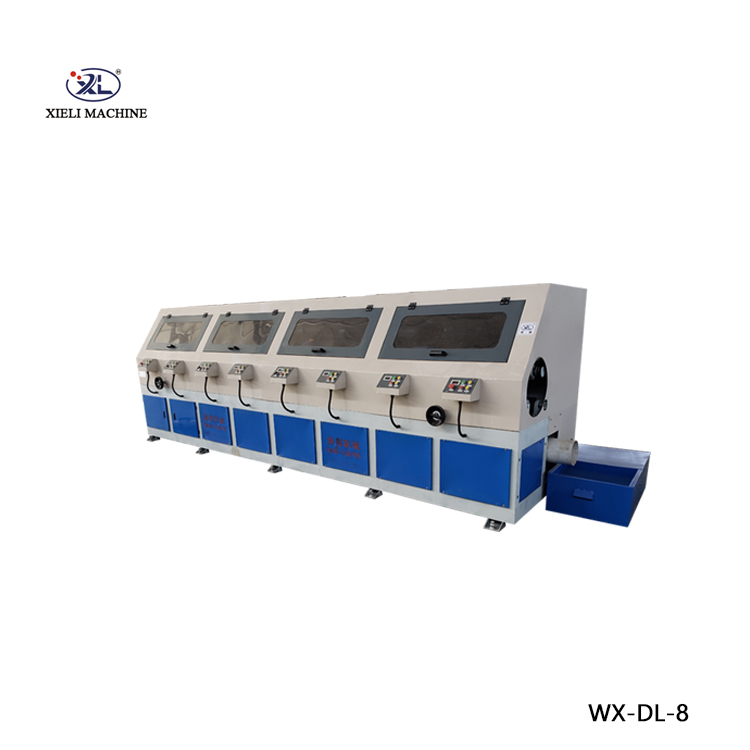

custom 24x24 centerless grinder

3. Customizability As the name suggests, the Custom 2024x24 is tailored to meet the specific needs of its users. Whether you require adjustments in wheel size, motor power, or operational speed, this grinder can be configured to fit your precise requirements.

4. Versatility The Custom 2024x24 is not only suitable for a wide range of materials but also for various sizes and shapes of workpieces. From small, delicate components to larger, heavier parts, this machine can handle it all, making it a valuable asset for diverse manufacturing environments.

5. Reduced Setup Time One of the significant challenges in machining is the time lost during setups. Custom 2024x24 minimizes this downtime through quick changeover capabilities, allowing operators to switch from one operation to another with minimal disruption to workflow.

6. Cost-Effectiveness While the initial investment may be considerable, the long-term savings gained from increased productivity, reduced labor costs, and lower material waste make the Custom 2024x24 a cost-effective choice for many companies.

Industry Applications

The Custom 2024x24 Centerless Grinder is utilized in various industries including automotive, aerospace, medical devices, and more. In the automotive sector, for example, it can efficiently grind components like valve stems and shafts, ensuring they meet stringent quality standards. In medical device manufacturing, the precision offered by this machine ensures that components are both functional and safe for use.

Conclusion

In conclusion, the Custom 2024x24 Centerless Grinder stands out as a leading solution for precision grinding needs in today’s demanding manufacturing landscape. Its unique design, combined with advanced technology and custom features, allows businesses to achieve unparalleled accuracy and efficiency. As industries continue to evolve, investing in such cutting-edge machinery will undoubtedly play a crucial role in maintaining competitive edges, ensuring quality output, and fostering innovation in precision machining techniques. Whether you are looking to enhance your productivity or improve the quality of your products, the Custom 2024x24 Centerless Grinder is a worthy consideration.