Centerless Grinder Manufacturers The Backbone of Precision Grinding Industry

In the realm of manufacturing, precision is paramount. Among the myriad of machinery utilized for this purpose, centerless grinders stand out for their unique ability to produce highly accurate cylindrical workpieces. Centerless grinder manufacturers play a critical role in the production and advancement of this essential equipment, ensuring that industries, from automotive to aerospace, can maintain the high standards required in today's competitive landscape.

Centerless grinding is a machining process that uses abrasive cutting to remove material from a workpiece. Unlike traditional grinding methods that require the workpiece to be mounted between centers, centerless grinding allows for the material to be held in place by two wheels—the grinding wheel and the regulating wheel. This process enhances efficiency and versatility, making it a preferred choice in various applications.

The first step in understanding the significance of centerless grinder manufacturers is recognizing their commitment to innovation. These manufacturers invest heavily in research and development to improve grinding technology. With advancements in CNC (computer numerical control) and automation, modern centerless grinders are becoming increasingly sophisticated, offering enhanced precision and speed. Features like touch screen controls, automatic loading and unloading systems, and real-time monitoring capabilities are becoming standard in high-end models.

Quality assurance is another critical focus for centerless grinder manufacturers. The components of centerless grinders must meet stringent tolerances, as even the slightest deviation can impact the final product's quality. Manufacturers employ a variety of testing techniques, such as vibration analysis and thermal imaging, to ensure that their machines operate flawlessly. By adhering to international standards like ISO 9001, these manufacturers guarantee that their grinders meet the quality and performance expectations of their clients.

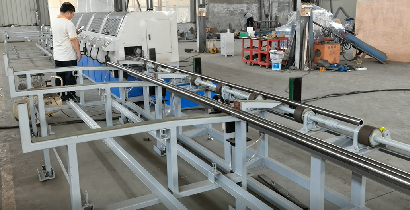

centerless grinder manufacturers factory

Furthermore, the importance of customization in the centerless grinding industry cannot be overstated. Different applications require specific grinding parameters, and manufacturers are increasingly offering tailored solutions to meet the unique needs of their customers. Whether it is the diameter of the grinding wheel, the type of workpiece material, or the desired surface finish, centerless grinder manufacturers strive to accommodate a diverse range of specifications.

Sustainability has also become a significant consideration in the manufacturing of centerless grinders. As industries worldwide pivot towards environmentally friendly practices, manufacturers are exploring ways to reduce waste and energy consumption. This includes developing machines that require less coolant and produce less debris, as well as employing energy-efficient motors and systems that minimize electricity usage.

Additionally, the globalization of the manufacturing industry has opened new avenues for centerless grinder manufacturers. With supply chains reaching around the world, these manufacturers are not only servicing local markets but also exporting advanced machinery to countries with burgeoning manufacturing sectors. This expansion brings about challenges, such as navigating different regulations and standards, but it also provides opportunities for growth and innovation.

In conclusion, centerless grinder manufacturers are indispensable players in the precision grinding landscape. Through their dedication to innovation, quality assurance, customization, sustainability, and global outreach, they ensure that the machinery they produce meets the evolving needs of diverse industries. As technology continues to advance, these manufacturers will remain at the forefront, driving the future of manufacturing with their state-of-the-art grinding solutions.