The Value of SS Pipe Polishing Machines in Modern Manufacturing

In the realm of modern manufacturing, the significance of maintaining high standards of product finish cannot be overstated. One essential tool that has emerged as a game changer in this domain is the stainless steel (SS) pipe polishing machine. These machines are specifically designed to enhance the surface quality of stainless steel pipes, ensuring that they meet the stringent requirements of various industries, including automotive, aerospace, food processing, and pharmaceuticals.

Understanding the Functionality of SS Pipe Polishing Machines

SS pipe polishing machines perform a crucial function in the manufacturing process. They utilize a combination of mechanical and chemical processes to refine the surface of stainless steel pipes, removing imperfections such as scratches, oxidation, and weld marks. By doing this, these machines not only improve the aesthetic appearance but also enhance the corrosion resistance and overall durability of the pipes.

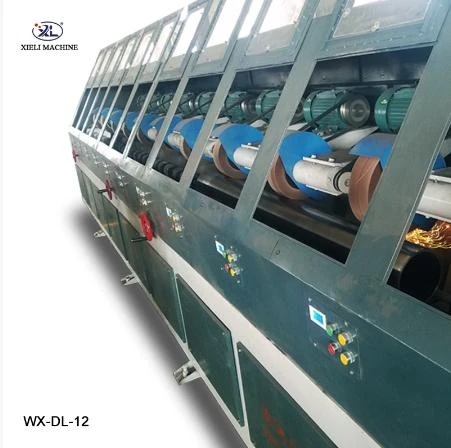

Typically, these machines operate through several stages, including grinding, buffing, and polishing, often using abrasives of varying grits. Advanced SS pipe polishing machines are equipped with automated features that allow for precise control over the polishing process, ensuring uniform finishes and reducing human error. This level of automation not only boosts productivity but also ensures consistency in quality, a critical factor in industries where safety and reliability are paramount.

Key Benefits of Using SS Pipe Polishing Machines

1. Enhanced Surface Quality The primary advantage of employing SS pipe polishing machines is the significant improvement in surface quality. A polished surface reduces the likelihood of corrosion and increases the lifespan of the pipes. Moreover, a smooth finish enhances the flow of fluids in pipelines, making it especially vital in industries like oil and gas.

ss pipe polishing machine quotes

2. Increased Production Efficiency Automated SS pipe polishing machines significantly reduce the time required for manual polishing, thus increasing overall production efficiency. By streamlining the polishing process, manufacturers can meet high demand without compromising quality or increasing labor costs.

3. Consistency and Precision The precision offered by these machines ensures that every pipe meets the same standards, eliminating variations that occur with manual polishing. This consistency is crucial, as even minor discrepancies in pipe surface quality can lead to failures in critical applications.

4. Cost-Effectiveness While the initial investment in a high-quality SS pipe polishing machine may be substantial, the long-term savings on labor and material costs, coupled with increased production capacity, make these machines a cost-effective solution. Manufacturers can reduce waste and optimize their resources more effectively.

5. Regulatory Compliance Many industries are governed by strict regulations regarding product quality and safety. SS pipe polishing machines enable manufacturers to adhere to these standards more easily. A smooth and polished surface on stainless steel pipes can help meet industry specifications, which is essential to avoid costly recalls and enhance brand reputation.

Conclusion Investing in the Future of Manufacturing

As industries continue to evolve, the demand for high-quality stainless steel pipes remains strong. Investing in SS pipe polishing machines is not just a choice—it's a necessity for manufacturers aiming to stay competitive in a rapidly changing market. By improving surface finish, increasing production efficiency, and ensuring compliance with industry standards, these machines provide manufacturers with a powerful tool to enhance their operational capabilities.

In conclusion, the rise of SS pipe polishing machines is a testament to the ongoing pursuit of excellence in manufacturing. As technology advances and industries become more demanding, these machines will undoubtedly play a pivotal role in shaping the future of stainless steel pipe production, driving innovation, efficiency, and quality to new heights. Therefore, for any manufacturer serious about their competitive edge, integrating SS pipe polishing machines into their production lines is a strategic move that will yield dividends for years to come.