Understanding the Costs of Centerless Grinding Machines in China

Centerless grinding machines play a pivotal role in the manufacturing and machining industries, especially for high-precision components. When it comes to sourcing these machines, China has become a significant player in the market due to its robust manufacturing capabilities and competitive pricing. This article explores the factors influencing the price of centerless grinding machines in China and provides insights for prospective buyers.

Factors Influencing Price

1. Machine Specifications The price of centerless grinding machines varies widely based on their specifications. High-end machines equipped with advanced technologies, such as CNC (Computer Numerical Control) and automation, will typically have higher price tags. Basic models, suitable for simpler applications, are available at lower costs.

2. Brand Reputation Well-established brands that are known for quality and reliability generally command higher prices. Companies that have built a reputation for durability and precision machining often attract customers willing to pay a premium for their products, while lesser-known brands offer more budget-friendly options.

3. Material and Construction Quality The materials used in building the machines affect their durability and precision. Machines made with high-grade steel and components tend to be more expensive but offer better longevity and performance. Weighing the initial cost against the potential for long-term savings is crucial.

4. Market Demand and Supply Prices are also influenced by market dynamics. Increased demand for precision machined components across various industries can lead to a rise in machinery costs. Conversely, an oversupply of machines may drive prices down. Keeping an eye on industry trends can help buyers make informed decisions.

5. Technological Advancements As technology evolves, so do manufacturing processes. Newer models of centerless grinding machines may feature enhanced automation, improved efficiency, or advanced monitoring systems. Such enhancements can justify a higher cost as they can lead to increased productivity and reduced operational downtime.

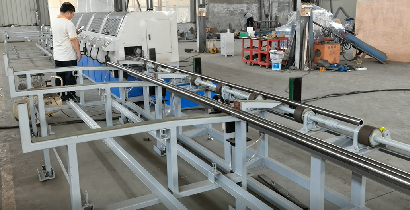

china centerless grinding machine price

6. After-Sales Support and Warranty The level of after-sales service and warranty offered by manufacturers can impact initial pricing. Companies that provide comprehensive service packages and extended warranties often charge more but can deliver peace of mind and long-term savings through reduced maintenance costs.

Price Range for Centerless Grinding Machines in China

In China, the prices for centerless grinding machines can range significantly based on the aforementioned factors. Entry-level machines may be available for as low as $10,000 to $20,000. Mid-range machines, which offer more features and better precision, typically fall within the $20,000 to $50,000 bracket. Higher-end models comprising advanced automation and superior engineering can exceed $50,000, with some specialized machines reaching prices well over $100,000.

Sourcing Options

When looking to purchase a centerless grinding machine from China, buyers have several sourcing options. Directly contacting manufacturers can often yield the best prices, as it eliminates intermediaries. Popular platforms such as Alibaba and Made-in-China provide extensive listings from various suppliers, allowing buyers to compare prices and specifications easily.

Conclusion

Investing in a centerless grinding machine is a significant decision that requires careful consideration of various factors influencing price. Buyers should assess their specific machining needs, budget, and the long-term value of the equipment. By understanding the dynamics of the market and the options available, including the price ranges from various manufacturers, businesses can make informed decisions that align with their operational goals.

As China continues to solidify its position as a leader in manufacturing, the accessibility and range of centerless grinding machines will likely keep evolving, offering more choices for industries reliant on precision machining. Thus, keeping abreast of new developments and prices can be immensely beneficial for manufacturers looking to optimize their production capabilities.