Understanding the Best Centerless Grinder Regulating Wheels

Centerless grinding is a precision machining process that is widely used in manufacturing to produce high-accuracy, high-tolerance cylindrical parts. One of the critical components of a centerless grinder is the regulating wheel, which plays a vital role in controlling the speed, feed rate, and size of the workpiece during the grinding operation. This article explores the importance of selecting the best centerless grinder regulating wheels to optimize performance and achieve superior grinding results.

What Are Regulating Wheels?

Regulating wheels, also known as feed wheels, are used in centerless grinding machines to control the rotation and movement of the workpiece. The design and material of the regulating wheels significantly affect the grinding process, influencing factors such as grip, stability, and the overall efficiency of the machinery. The correct type of regulating wheel can improve productivity, enhance the quality of the finished product, and reduce operational costs.

Types of Regulating Wheels

The choice of regulating wheels varies based on the specific application and the material being processed

. Generally, they can be categorized into two main types1. Rubber Regulating Wheels These wheels provide excellent traction and are often used for grinding softer materials. They are preferred when there is a need for high friction between the wheel and the workpiece, ensuring efficient feeding and control.

2. Metal Regulating Wheels Typically used for harder materials, these wheels are more durable and can withstand higher forces. They provide excellent dimensional accuracy but may require a more sophisticated setup to ensure proper grinding.

Factors to Consider When Choosing Regulating Wheels

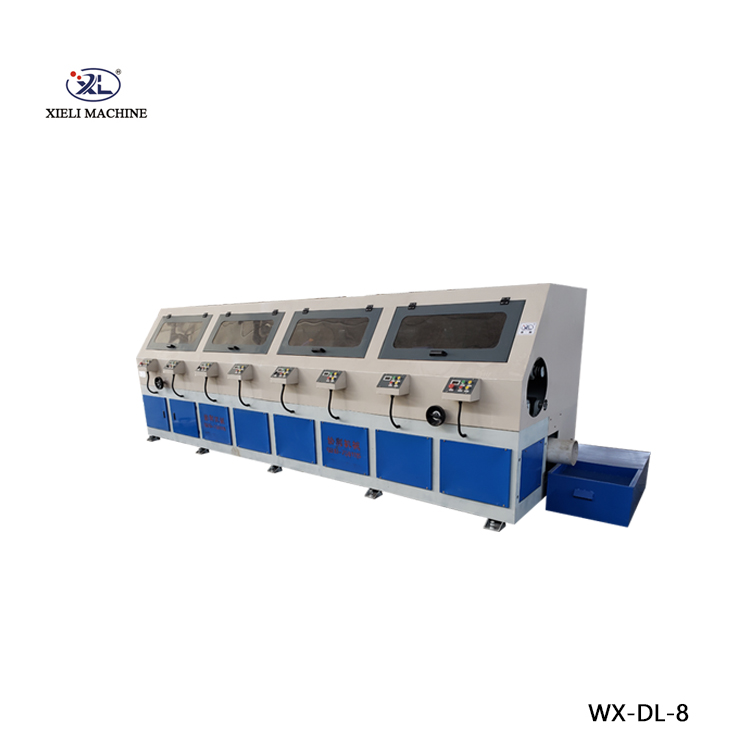

best centerless grinder regulating wheels

When selecting the best regulating wheels for centerless grinding, several factors must be taken into account

1. Material Compatibility The material of the regulating wheel should be compatible with the workpiece material. For instance, rubber wheels are ideal for softer metals, while metal wheels work best for harder alloys.

2. Wheel Hardness The hardness of the wheel affects how it grips the workpiece. Softer wheels provide higher friction but may wear faster, while harder wheels may last longer but provide less grip.

3. Size and Shape The diameter and width of the regulating wheel should match the specifications of the centerless grinder. An incorrectly sized wheel can lead to operational issues and poor grinding results.

4. Surface Finish The finish of the regulating wheel surface can impact the efficiency of the grinding process. A smooth surface may reduce friction, while a textured surface could enhance grip.

5. Operating Conditions Consider the specific environmental conditions in which the grinding operation will take place. Factors such as moisture, temperature, and the presence of coolants can influence the choice of material and wheel design.

Conclusion

Choosing the right regulating wheels for centerless grinders is crucial to achieving optimal grinding performance. By understanding the different types of wheels available and the factors that influence their performance, manufacturers can select products that enhance efficiency, improve the quality of finished parts, and reduce overall operational costs. Investing in high-quality regulating wheels ultimately leads to better machining results, making it a vital consideration in the centerless grinding process. Selecting the right wheel can significantly impact productivity in any manufacturing setting, emphasizing the need for careful analysis and selection based on specific application requirements.